Numerical Simulation of PCB-Coil-Layouts for Inductive Energy Transfer Systems

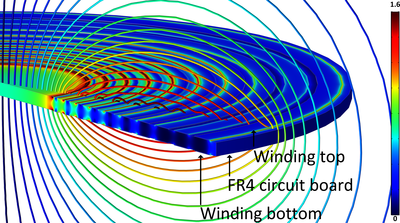

This paper presents the two dimensional (2D) Finite Element Method (FEM) COMSOL Multiphysics® model of a PCB-Coil layout. The model comprises of different coil layouts for sake of comparison. The scientific goal of the simulation is to find an optimized arrangement with a high quality factor of the coil. The case of application for the simulated coils are inductive contactless energy transfer systems with a low magnetic coupling. In recent years, contactless inductive energy transfer systems have become more and more popular. For an efficient system it is advisable to use a frequency which is, with respect to the system boundaries of inverter and rectifier, as high as the quality factor Q of the coil arrangement is increased with the higher frequency. The PCB coils developed in this simulation are used for inductive energy transfer in systems with small installation space and a low power transfer rate up to 100W.

How the COMSOL Multiphysics® Software is used: • AC/DC Module with Magnetic and Electric fields. • Study: For the study a Frequency Domain is selected, all results in this paper are based on a fixed frequency of 500 kHz. • Based on the 70µm PCB copper layer thickness compared to the 20cm air region, a user controlled mesh is used. To simulate the current density in the 70 µm copper layer a quadrilateral mesh with an element size of 14 µm is selected. • Different coil geometries are compared with each other with a parameterized sweep. • Final Paper: planned to confirm the optimum of different geometries with the Optimization Module.

Results: -The magnetic flux density depending on the distance measured from the PCB’s top etch layer for three different coil arrangements is presented. -Current density measured in the middle (35µm) of the top winding for three different coil Arrangements is presented. -Based on simulation results an optimized geometry is found.

Download

- maier_poster.pdf - 13.66MB

- maier_paper.pdf - 8.7MB

- maier_abstract.pdf - 0.03MB