Radio frequency Drying Based on Finite Element Method

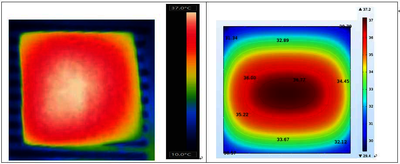

Radio frequency (RF) drying is a novel drying technology. During the RF drying process, the internal and external temperature of the food material is elevated simultaneously when traditional heating method relies on heat transfer from the surface to the inside, which greatly improving the drying speed. In order to better understand the RF drying process, this article built up a model for potato cubes in RF drying and studied its heat, mass and momentum transfer process. First, the potatoes were cut into a cube shape measuring 40 mm x 40 mm x 40 mm, and placed in a RF heater drying for 1 hour. The mass of the potato samples were measured every 5 minutes and the surface temperature distribution was taken using an infrared camera. Then, COMSOL Multiphysics® was used to build up a physical model and solve coupling heat and mass transfer equations in porous media for obtaining the temperature, vapor pressure and moisture distribution in potato cubes in RF drying. The simulation results of the numerical model were compared with the experimental results to verify the reliability of the model. Results shows the mass of potato cubes after drying decreased from 70.18g to 64.43g and the simulated final mass is 64.21g. The sample temperature at the corners rises first, and then the temperature in the middle exceeds the corners. The hot spot temperature rises up to 35°C in experiment and to 33°C in simulation. The electric field lines perpendicular to the plate around the sample will be adsorbed by the sample. As the moisture distribution inside the potato sample changes, the angle of the electric field line increases. The saturated concentration of water vapor increases with the increase of temperature, and the content of water vapor in the sample increases as drying proceeds. This study explains the mechanism of RF drying of porous media and provides an effective method for revealing the RF drying principle.

Download

- 张_presentation.pdf - 1.72MB

- 张_poster.pdf - 1.07MB

- 张_abstract.pdf - 0.05MB