Thermal Response of Encapsulants for Photovoltaic Applications

Photovoltaic (PV) devices on its operational life are exposed to the action of environmental conditions, which can produce damage either chemically or mechanically. For this reason, traditional PV panels are made of different materials including glass, encapsulant, solar cells, backsheet and aluminum frames. The glass and the encapsulant must offer a low thermal resistance and a high transmissivity in the spectral range where solar cells operate, whilst providing protection against weathering-induced and environmental damages. Particularly, the encapsulant is a polymer material used to provide mechanical stability (deformation and adhesion) and electrical insolation to the solar cells and its electrical interconnectors.

The aim of this work is to study the thermal response of the encapsulant in the context of indoor accelerated aging when embedded within glass-encapsulant-glass (G-E-G) structures and in small factor PV module (micro-module). For this purpose, several samples are placed within a chamber hosting a mercury-xenon arc lamp emitting most of its radiation in the ultraviolet (UV) spectral range. Upon illumination, the encapsulant suffers thermolysis due to the absorption of high energy photons and subsequent bond braking and free radical production, leading to the material degradation.

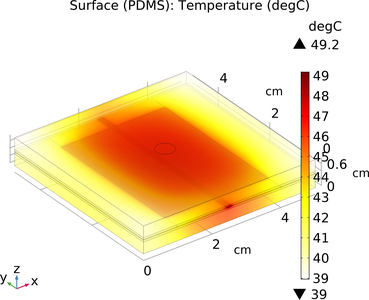

To assess the thermal description of the encapsulant, we created a 3D geometry of G-E-G structure and the micro-module. We used the Heat Transfer in Solids physics interface in COMSOL Multiphysics®, performing both a time-dependent and a stationary study. The input parameters in the heat equation such as heat capacity, thermal conductivity and density of materials were extracted experimental work in the literature. The heat generation due to photon absorption was included by coupling the heat equation with the Lambert-Beer’s equation. This law was applied as a Dirichlet boundary condition (BC) to the material dominating the heat generation, that is, the encapsulant in the case of the G-E-G structure and silicon in the case of the micro-module. Once photons are absorbed, heat is transferred to the neighbor materials though Fourier’s law of thermal conduction. In addition, the thermal convection on the glass surfaces and the emission of thermal radiation through the Stefan-Boltzmann’s law were also considered.

Simulations were run for specific combinations of the thermal parameters for ethylene-covinyl acetate (EVA) and polydimethyl siloxane (PDMS) encapsulant materials, by performing a sweep in the defined time-dependent and stationary study. It was found that the model reproduces experimental measurements of the surface temperature for the G-E-G structure, reaching ~50 °C in the stationary regime. In addition, the temperature distribution of the micro-module agrees with the thermal response of PV modules operating under illumination, showing that a PV module using different encapsulants leads to dissimilar temperature profiles.