Thermal Stratification Analysis of a Room-Integrated Large Hot Water Storage

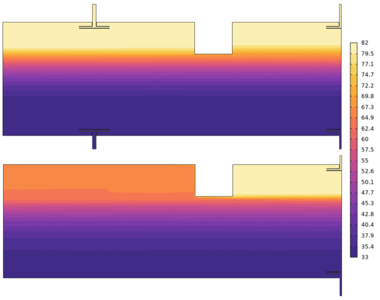

While common hot water storage geometries are slim and high, this work deals with the conversion of a preexisting cellar room into a hot water storage with an area of 550 m² and a height of only 2.9 m. Next to the poor area-to-height ratio, the room contains columns and bearers for static reasons which complicate the generation of a good thermal stratification. A possible advantage or disadvantage is that the bearers ensure that the upper half of the storage is divided into three separate “chambers” of 36 m length and 4.9 m width. This could lead to less mixing in the storage tank and complicates the in- and outlet positioning on the top. Therefore, a non-isothermal turbulent flow model was used in the COMSOL Multiphysics® Heat Transfer Module. At first, a 3D geometry was built by importing via LiveLink™ for Revit®. Whereas the geometry was kept simple, the big challenge has been to deal with the size of the geometry since the room has a length of 36 m and a width of 15.5 m. To simplify the geometry, we created a 2D model in place of the 3D geometry. With the use of symmetry conditions, this model was further reduced in size. To make sure the 2D model reflects the reality of a stratification process within a hot water storage tank, we began with a comparison of measurement data of a different existing storage with the first calculations. These model results agreed with the preliminary experimental results, although we dealt with a few complications modelling the diffusion. With the model of the cellar storage tank, we analyzed whether thermal stratification over the whole area is generally possible. In addition, the optimal number and location for inlet devices as well as the possibility of a horizontal stratification were investigated. For comparison purposes and to ensure the robustness of the results, our partners are simultaneously performing the simulations with the software Simcenter™ STAR-CCM+™ by Siemens®. First results show that due to the bearers, the installation of an in- and outlet device in every “chamber” at the top is necessary. Finally, a higher amount of inlet devices over the storage length (36 m) does not have such a significant impact on the hottest layer generation to justify the installation of more than one inlet device per chamber.

Download

- Solka_4641_poster.pdf - 0.57MB