See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

The current and energy transfer to cathodes of vacuum arcs usually occurs in bright, narrow regions, known as cathode spots. Owing to extreme conditions in these spots, the cathode surface is eroded: electrode material is vaporized, and craters and molten metal jets are formed. The study ... Read More

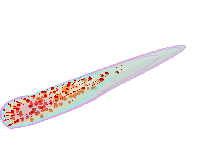

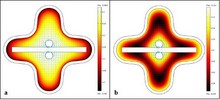

Materials such as aluminium with high thermal and electrical conductivities are of industrial interest, particularly for the automotive industry in the current context of increasing production of electric vehicles. The reflective properties of this material make it difficult to process ... Read More

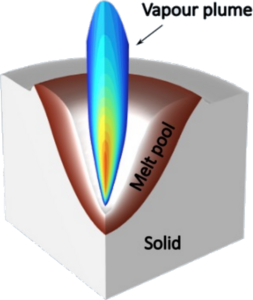

Arc welding is a widely used process in heavy industry for the assembly of metallic components. To ensure high-quality welds, it is essential to understand both the welding process and the complex interactions within the melt pool. Numerical simulation is employed as a predictive tool to ... Read More

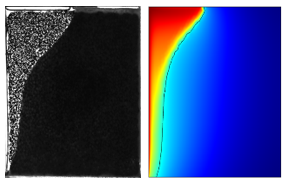

Laser technologies such as welding, cutting and metal deposition are widely used in the industry. High quality requirements regarding process products cause that there is often a need to monitor the process. For this purpose, optical sensors integrated with a laser head are often used. ... Read More

Laser cladding is an additive manufacturing process, where a laser beam creates a melt pool, into which powder is fed from a powder nozzle. Due to the feed motion of the laser beam and the powder nozzle relative to the workpiece, coatings and 3D parts can be deposited, which consist of ... Read More

In this paper, a numerical study is conducted on the melting and solidification process of metal foam/paraffin wax with cyclic heating and cooling. A mathematical model based on the Brinkman-Frochheimer extended Darcy equation and the local thermal non-equilibrium model (LTNE) is ... Read More

Thermocouples are widely used in industry for process temperature measurement. Calibration drift is a well-known problem which adversely affects process control, particularly in harsh environments (e.g. high temperature). To overcome this, a mechanism for self-calibration of ... Read More

Additive manufacturing processes are increasingly used for designing metallic parts with complex geometries. The current needs are focused on the manufacturing of large-scale parts, typically of meter range. However, for such dimensions, the traditional trial-and-error methodology used ... Read More

Sodium/metal chloride storage batteries, used in hybrid propulsion applications, provide high energy and power densities safely and reliably. To understand the dynamics of electrochemical cycling, a high-temperature sodium/ferrous chloride storage cell was modeled in two dimensions. The ... Read More

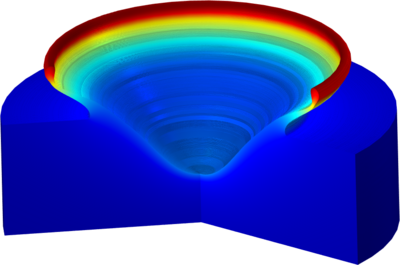

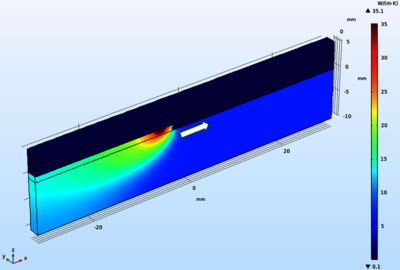

Laser metal deposition is widely adopted for coating, reparation and 3D printing. Using COMSOL, we have developed a numerical model with full coupling of laminar fluid flow and heat transfer. The Marangoni effect is considered to capture the enhanced convective heat transfer as well as ... Read More