See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

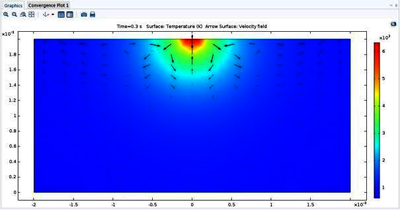

Marangoni flow affects the heat and mass transfer occurring in the molten metal regions in welding and additive manufacturing processes. It originates from the surface tension gradient (∂γ/∂T) induced at the melt pool surface due to the temperature difference. The flow pattern within ... Read More

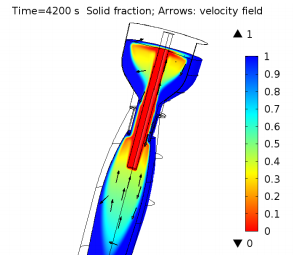

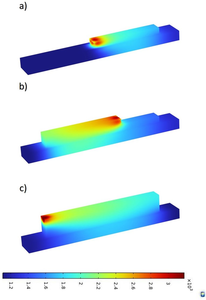

Introduction Numerical modeling of melt-casting is becoming a popular tool for the energetic materials and explosives industry. Compared to traditional metal casting, the cooling cycle for explosive melts is significantly longer because of their high Prandtl numbers [1]. Improving the ... Read More

Laser cutting process is usually employed in machining process, however it is also applied for dismantling nuclear facilities. Contrary to mechanical processes where tools wear out quickly and are often renewed, laser cutting process is a contactless approach, therefore there is no ... Read More

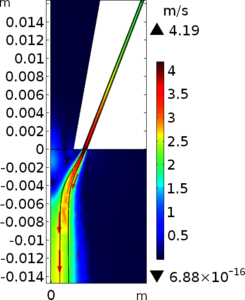

Arc plasma can heat and melt the metal material and flows of molten metal can be affected by several forces such as Lorentz force which is ruled by current, Marangoni force controlled by surface tension, buoyancy force, and arc drag force. Usually, surface tension variation is determined ... Read More

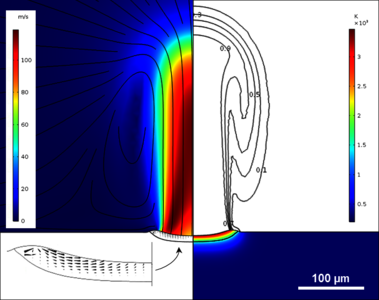

Laser drilling of titanium and its alloys is widely used in aerospace industry, as it offers selective removal of material at high accuracy and speed. However, laser drilling often inherits defects such as large heat affected zone, micro cracks and recast layer. These defects depend upon ... Read More

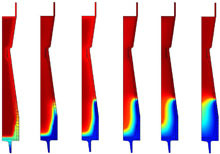

Additive manufacturing gathers technologies where near net shape components are produced by depositing successive layers of materials. Among these technologies, the Layer Beam Melting (LBM) process – often referred to as Selective Laser Melting (SLM) – is garnering industrial interest, ... Read More

Present work is done in the framework of the SisAl Pilot EU project, which aims at optimising the silicon production in Europe by recycling materials and using a carbon-emission friendly technology. The silicon production experiments are conducted on laboratory and pilot scales in ... Read More

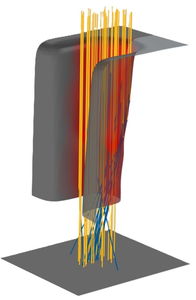

The Laser Metal Deposition process (LMD) is a rapid free form fabrication method which can be used to manufacture new near net shape metallic components, to repair used ones or to add functional parts on existing ones. This process is composed by multiple gas streams flowing inside a ... Read More

In this paper, we present a study of the simulation of Directed Energy Deposition (DED) Additive Manufacturing (AM) using a multiphysics approach. We use a combination of Heat Transfer in Fluids, Solid Mechanics and Laminar Flow physics to accurately simulate the DED process. The ... Read More

A solidification process of casting explosives in shell is studied in this paper. An enthalpy method approach is used to model the solidification process. Both the thermal and mechanical effects are taken into account. An ALE (Arbitrary Lagrangian-Eulerian) method is used to represent ... Read More