See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

In this work, finite element method (FEM) based commercial software COMSOL Multiphysics® has been used to perform two-dimensional simulation of droplet formation inside T-junction microchannel. The laminar two-phase flow, level set module modules of COMSOL Multiphysics® with free ... Read More

Over the years, researchers have been investigating a variety of approaches to understand the droplet dynamics in a microchannel due to its vast applications in various fields. At low Reynolds number, surface tension and viscosity dominate the flow in the microchannel. In this study, the ... Read More

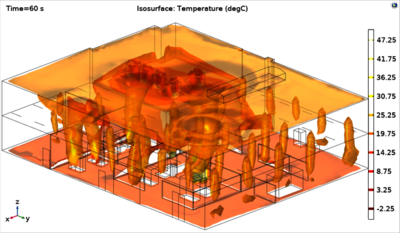

This paper presents numerical investigation on heated blocks under natural convection in a vertical channel for heat transfer enhancement. Three dimensional, steady state, incompressible, laminar natural convection in a vertical channel have been studied. The problem is modeled and ... Read More

A thorough study on the adsorption behaviour of carbon dioxide (CO2) on silica aerogel is critical for CO2 sequestration and recovery. Although CO2 sorption focuses mainly on the lab scale setup, research on the larger bulk counterparts, which is used at industry central facility is ... Read More

In this paper, a simulation of fluid flow in a distribution manifold has been considered. An axial inlet has been taken and the variation of velocity and pressure in the header tube and the outlet tubes have been observed. The effect of various parameters such as the Area Ratio(AR) that ... Read More

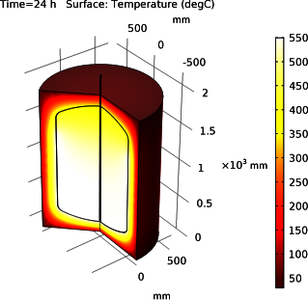

Preheating condition of salt storage vessel was analysed in COMSOL Multiphysics® to obtain the temperature distribution and time of heating and cooling cycle. Salt storage vessel is a stainless steel cylindrical vessel with surface heaters. The vessel is mounted vertically and insulated ... Read More

Microfluidic device based applications are gaining importance since the last few years, mainly because of its potential of replacing large-sized equipment with relatively compact devices. Micro-channel heat sinks are one of the widely investigated applications as they can provide a very ... Read More

In current work, diffusion processes of oil spills through a thin layer of porous composite materials based on crumb rubber are investigated. Model setup includes a concept of layer built of crumb rubber particles (and composite constituents) distributed on the solid surface, gradually ... Read More

In biotechnology and medicine, cells are frequently grown on scaffolds with a three-dimensional channel structure. The oxygen and nutrient supply of the cells is realized by a medium flowing through the channels of the scaffolds. However, it is often difficult to obtain a confluent ... Read More

Environmental factors such as temperature and humidity can significantly affect the quality of the metal powder used in power bed fusion additive manufacturing, leading to variations in the integrity of finished components. It is therefore important to monitor and minimize the exposure ... Read More