See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

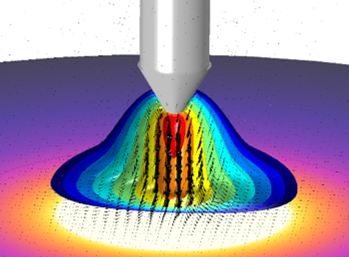

The heat and fluid flow calculation inside the melt pool in welding processes is a complex challenge. It can be useful to predict defects in the weld seam or to study the influence of some process parameters. Even if the required equations are mastered over the last few years, the cost ... Read More

A wide variety of engineering applications, such as electronics, solar collectors, and internal combustion engines produce heat. This heat can be a positive or negative aspect for a particular application. Enhancing heat transfer has encouraged many researchers to investigate various ... Read More

Here we present a simulation for evaluation of novel obscurant candidates under high-energy laser (HEL) illumination. This approach incorporates thermal modeling into obscurant characterization, allowing for evaluation of the temperature increase of the candidate obscurants as well as ... Read More

As a part of the Pan-Canadian framework for clean growth, Canada is intent on meeting its 2030 emission targets for which 17% of Canada’s total Green House Gas emissions come from buildings. Given this challenge, emphasis is being placed on developing building designs having greatly ... Read More

Selective Laser Melting (SLM), like many other additive manufacturing techniques, offers flexibility in design expected to become a disruption to the manufacturing industry. The current cost of SLM process does not favor a try-and-error way of research; which gives more room for ... Read More

Heat waste harvesting with thermoelectric systems is a clean, environmentally friendly energy producing option among several methods currently considered. The present study investigates the ability of COMSOL Multiphysics® simulation software to develop models that generate data in good ... Read More

We used COMSOL Multiphysics® simulation software to model mass flow calorimetry in a metal-hydride chemisorption reaction. Using a reaction chamber with 100W input, we measured the temperature of flowing water in contact with the chamber and calculated the heat output of our reaction. ... Read More

Bi2Sr2CaCu2O8+δ (Bi 2212) is being developed as a high temperature superconductor (HTS) technology with practical use in ultra-high field (+30 T) magnets. A critical processing step for this conductor is a ~890 degC heat treatment at elevated pressure (~50 atm). The reaction of this ... Read More

Numerical study of fluid flow and heat transfer in a finite three-dimensional rectangular, horizontal duct of length to width, and length to height ratio of 12:1 is investigated in this study. The left wall of the duct is uniformly heated while the right, top, and bottom walls are ... Read More

Printed circuit heat exchanger (PCHE) is a key component in many energy and power systems, such as concentrated solar power plant, nuclear power plant, aircraft, etc. In this paper, the thermal and fluid performance of a lab-scale PCHE is analyzed using COMSOL Multiphysics® simulation ... Read More