See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

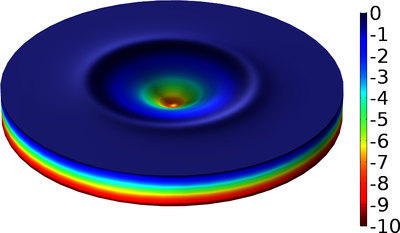

Two friction stir welding models are presented – a global thermal model using the temperature dependent heat source and a local material flow and heat generation model allowing for detailed investigation of different contact conditions. The two models are coupled into a larger local ... Read More

Actual trends in lightweight construction and safety-relevant technologies cause an increasing demand for reliable design of joining connections. Increasing power density and compact design require dimensioning of joints with low safety factors. Thereby additional security measures are ... Read More

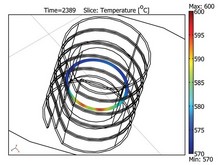

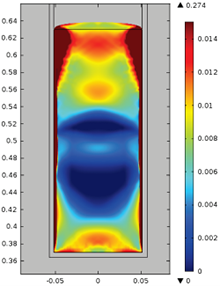

The induction heating coils used in the plutonium casting furnaces at the Los Alamos National Laboratory are studied here. A cylindrical graphite test article has been built, instrumented with thermocouples, and heated in the induction coil that is normally used to preheat the molds ... Read More

Laser welding is often considered to be a superior technique over different conventional welding methods and has been gradually evolved as an efficient manufacturing process. It is a high energy density fabrication process and generally employed for fabricating intricate shapes/contours ... Read More

To receive a stable quality in the injection molding process in the view of mechanically and thermally highly stressed components made by reactive resin systems, it is necessary to understand the material state along the processing chain. Up to date no measuring technology is available ... Read More

Casting product performance depends on material, flow, Process Temperature, Solidification, Shrinkage and residual stress. In a casting process, not all available resources are utilized effectively which results in low quality of casting, defects and metal wastage. Physics based modeling ... Read More

In this conference we have brought together a community that is scientifically diverse in an event that allows for inspiring contacts about the use of COMSOL Multiphysics. It is an event to connect with the Spanish and Portuguese COMSOL Multiphysics users and participate in training ... Read More

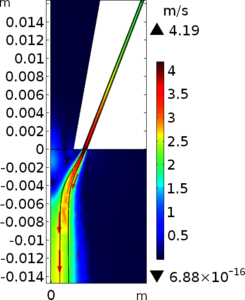

The Laser Metal Deposition process (LMD) is a rapid free form fabrication method which can be used to manufacture new near net shape metallic components, to repair used ones or to add functional parts on existing ones. This process is composed by multiple gas streams flowing inside a ... Read More

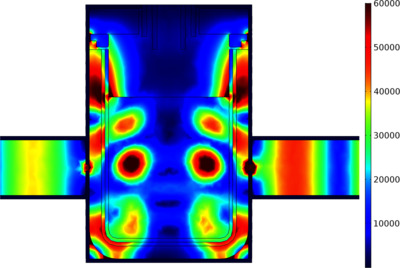

As a high-tech silicon producer, it is our goal to provide efficient and sustainable production technologies. This requires to constantly upgrade our production concept. Thus, material and design innovations are an inevitable part of our everyday work, which leads our microwave ... Read More

Pre-existing oil and gas wells and well bores represent highly permeable pathways for leakage of greenhouse gases; in Alberta alone leaks have been estimated to provide the equivalent of 3.5 million tonnes of CO2 per annum. In addition to abandoned wells without plugs, gas leakage may ... Read More