See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Introduction Numerical modeling of melt-casting is becoming a popular tool for the energetic materials and explosives industry. Compared to traditional metal casting, the cooling cycle for explosive melts is significantly longer because of their high Prandtl numbers [1]. Improving the ... Read More

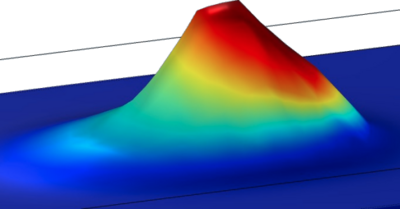

Laser powder bed fusion (LPBF) is one of the most beneficial manufacturing methods for its precision and ability to create parts with complex geometry, although high thermal gradient due to the considerable temperature difference between ambient and peak temperature appeared during laser ... Read More

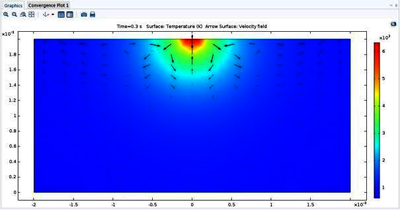

Marangoni flow affects the heat and mass transfer occurring in the molten metal regions in welding and additive manufacturing processes. It originates from the surface tension gradient (∂γ/∂T) induced at the melt pool surface due to the temperature difference. The flow pattern within ... Read More

Laser drilling of titanium and its alloys is widely used in aerospace industry, as it offers selective removal of material at high accuracy and speed. However, laser drilling often inherits defects such as large heat affected zone, micro cracks and recast layer. These defects depend upon ... Read More

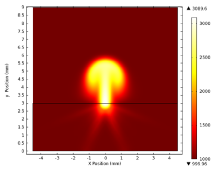

The current and energy transfer to cathodes of vacuum arcs usually occurs in bright, narrow regions, known as cathode spots. Owing to extreme conditions in these spots, the cathode surface is eroded: electrode material is vaporized, and craters and molten metal jets are formed. The study ... Read More

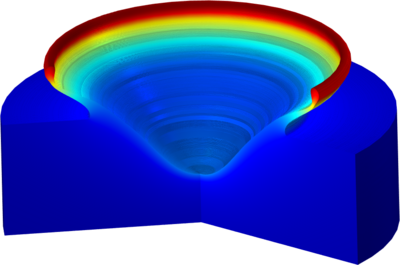

Electron beam has a wide range of applications in the material processing and joining techniques. Apart from that, it has also been utilized to simulate steady as well as transient fusion reactor relevant heat loads. Transient heat load events spontaneously occur in the fusion reactor. ... Read More

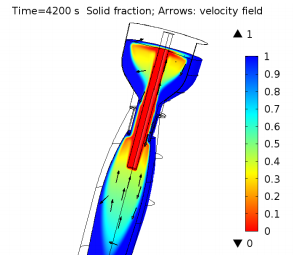

A solidification process of casting explosives in shell is studied in this paper. An enthalpy method approach is used to model the solidification process. Both the thermal and mechanical effects are taken into account. An ALE (Arbitrary Lagrangian-Eulerian) method is used to represent ... Read More

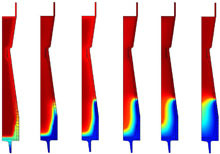

Laser percussion drilling is widely used in the aerospace industry to produce cooling holes in jet engine components. This process is a thermal, contact-free process which involves firing a sequence of focused optical pulses onto a target material [1-4]. During each optical pulse, the ... Read More

Calibration drift of temperature sensors is a well-known problem which adversely affects process control, particularly at high temperatures. Some new approaches are being developed [1,2], but degradation of resistive sensor elements is hard to prevent. To overcome this, graphene, which ... Read More

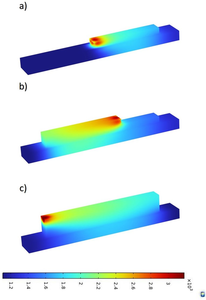

In this paper, we present a study of the simulation of Directed Energy Deposition (DED) Additive Manufacturing (AM) using a multiphysics approach. We use a combination of Heat Transfer in Fluids, Solid Mechanics and Laminar Flow physics to accurately simulate the DED process. The ... Read More