See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Injection molding is one of the most diffused processes for mass production of polymeric components. It is adopted in many fields, from the automotive one to the biomedical field. The aspects related to environmental pollution make mandatory the reduction of plastic wastes, especially ... Read More

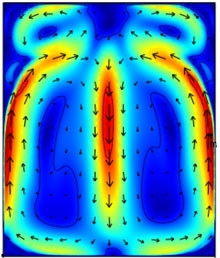

Introduction: Lithospheric delamination beneath the western U.S. is believed to be the driving mechanism responsible for the evolution of magmatic and topographic features observed at the surface in the western U.S.. This process requires hot asthenosphere to be in contact with the ... Read More

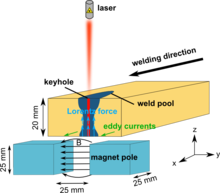

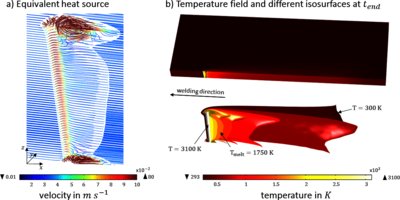

The application of an oscillating magnetic field on the high-power full-penetration laser beam welding process of a 20 mm thick stainless steel plate was numerically and experimentally investigated. In the simulations, three-dimensional heat transfer and fluid dynamics as well as ... Read More

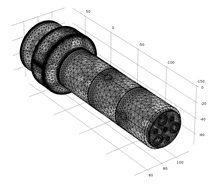

Present study discusses a new method of how to apply numerical simulation in COMSOL Multiphysics® software to improve the accuracy of polymer melts viscosity measurements. The main emphasis is placed on evaluating the effects of entrance and exit geometry of a capillary rheometer on ... Read More

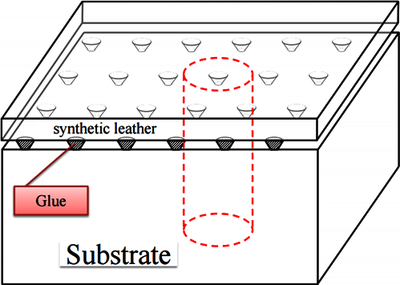

The lamination of substrates with thin coatings is commonly used in furniture, automotive and avionic industries. In the lamination process the hot melt adhesives are widely used and typically activated at temperatures from 80°C to 140°C by resistive heating. This requires a heat ... Read More

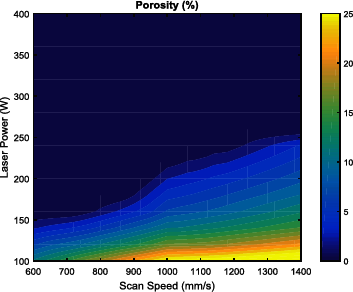

Additive manufacturing technology is becoming more popular for the fabrication of metal products as it offers rapid prototyping and large design freedom. However, part quality of components fabricated by current additive manufacturing technology is not comparable to that produced by ... Read More

A numerical simulation study, using COMSOL Multiphysics®, was carried out to examine the temperature and concentration fields in the dissolution process of silicon into germanium melt. This work utilized a simplified configuration which may be considered to be similar material ... Read More

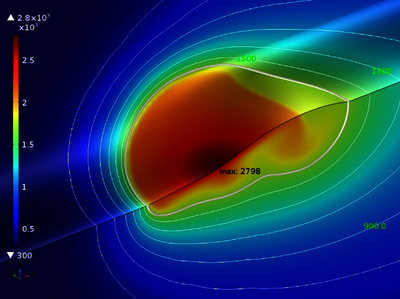

The Finite Element Method (FEM) has become an established numerical tool used for different academic and industrial purposes. It allows the prediction of weld pool geometry, thermal cycle, final distortion and residual stress field during and after fusion welding. The capability of the ... Read More

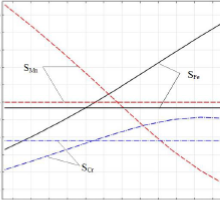

In this paper describes an original method for indirect measurement of the vapor pressure and temperature in the keyhole in electron beam welding. This method is based on the determination of the concentration of chemical elements in the vapor above the welding zone. Taking into account ... Read More

Arc current welding is a widespread process in heavy industry for the assembly of metallic components. In order to ensure the good quality of assemblies welds, it is appropriate to master the welding process but also to have a deep understanding of interactions with the weld pool and ... Read More