See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Carbon fiber (CF) reinforced polymer composites (CFRP) have begun to replace Al-Zn-Mg alloys in applications which require high strength-to-weight ratios. The anisotropy of CFRP composites is a result of melt crystallized extrusion techniques that impart an inherent directionality to the ... Read More

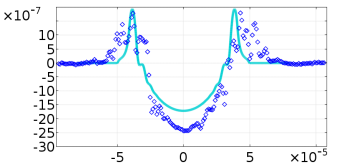

The article deals with the magnetically-supported high-power full-penetration laser beam welding of aluminum. A stationary simulation was conducted accounting for the effects of natural convection, Marangoni convection and solid-liquid phase transition as well as an electromagnetic ... Read More

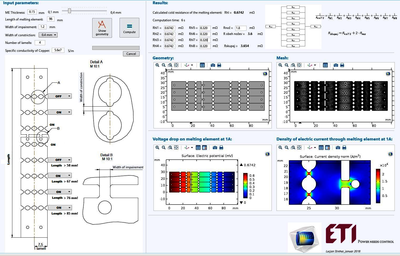

ETI is one of the world’s leading manufacturers of fuses. Different standard sizes, rated voltages, rated currents and tripping characteristics mean more than 750 different types of products. Additionally, our customers sometimes require fuses specifically designed for their needs. Our ... Read More

Three-dimensional flow analysis was performed by using COMSOL Multiphysics Chemical Engineering Module for the purpose of analyzing the flow properties and finding out the operating points of a test domain. Using material property table for an exemplary melt of LDPE (Low-Density ... Read More

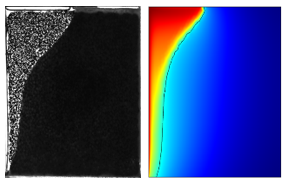

Electrical Discharge Machining (EDM) is a non-conventional process used for machining electrically conducting materials. In die sink-EDM, sparks are generated between tool and workpiece resulting in heating of both electrode surfaces and creating a melt pool of metal which leads to ... Read More

Kennedy Space Center is leading research work on lunar O2 generation via electrolytic reduction of regolith. The metal oxide present in regolith is dissociated into oxygen anions and metal cations leading to the generation of gaseous oxygen at the anode and liquid metal at the cathode. ... Read More

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. The objective of the work presented in ... Read More

In this paper, a numerical study is conducted on the melting and solidification process of metal foam/paraffin wax with cyclic heating and cooling. A mathematical model based on the Brinkman-Frochheimer extended Darcy equation and the local thermal non-equilibrium model (LTNE) is ... Read More

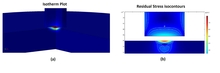

A Laser-welded blank (LWB) consists of steels of different thicknesses and/or grades welded together to produce a single blank prior to the forming process. LWB are mostly used in the automotive field where the high productivity of the laser welding process is an advantage. Numerical ... Read More

Electric Arc Furnaces (EAF) use graphite electrodes to strike an arc to melt scrap steel, recycling it for further use. These graphite electrodes oxidize and are consumed over time. To maintain operation new electrodes are attached to others via a joint of complex geometry and fed ... Read More