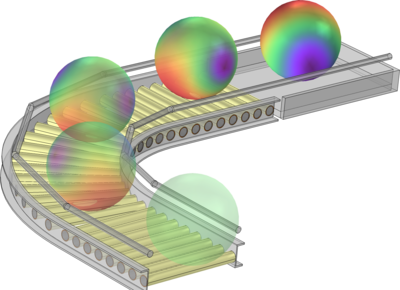

Dynamics of a Roller Conveyor

Application ID: 102661

Roller conveyors are commonly used in warehouses, manufacturing units and baggage handling applications to transport objects from one place to other by gravity, power, or manually. A typical roller conveyor consists of an array of moving rollers arranged either in a straight or curved manner and supported by frames. It is generally made of plastic, mild steel or stainless steel.

This model simulates the dynamics of a roller conveyor transporting a spherical object or a ball. Here, multiple cylindrical rollers are inserted between two C-sectioned beams. Cylindrical guideways are provided on both sides of the conveyor to prevent the ball falling off from rollers. The rollers are rotating about their axes, while the frames and guideways are fixed. On reaching the other end, the ball is collected in a rectangular tray. All components of the system are assumed rigid. Using rigid body contact with friction, contact is modeled between ball and rollers, ball and guideways, as well as ball and the surfaces of the tray. The connection between rollers and the frame is simplified using hinge joints. A transient study is performed to analyze the dynamics of ball, contact and friction forces, and energy dissipation due to friction.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.