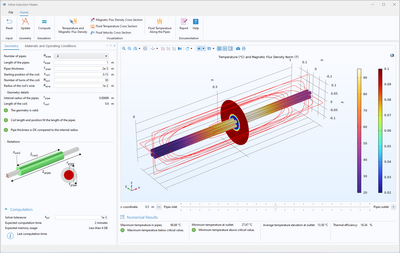

Inline Induction Heater

Application ID: 35541

This app demonstrates the following:

- A model using symmetry while the results are visualized in full 3D

- Provides info if the results are above or below certain critical values

- Selecting predefined or user-defined materials

- Error control of geometry parameters using methods and presentation of possible errors using card stacks

- Sliders and buttons to control the position of the slice when visualizing the results with a slice plot

The app computes the efficiency of a magnetic induction apparatus for the heating of liquid food flowing in a set of ferritic stainless steel pipes.

Ferritic stainless steels become more and more used in food processing due to their relatively low and stable price, and their magnetic properties that allow using new heating techniques.

A circular electromagnetic coil is wound around a set of pipes in which a fluid flows. The alternating current passing through the coil generates an alternating magnetic field that penetrates the pipes, generates eddy currents inside them, and heats them up. Then heat is transferred to the fluid essentially by conduction.

Various configurations are available for the set of pipes (number, length, thickness, material) and for the coil (number of turns, wire radius, current density, and excitation frequency) to optimize the heat exchange with the fluid, while ensuring homogeneous temperatures within it for a given flow rate.

This application example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.