The Application Gallery features COMSOL Multiphysics® tutorial and demo app files pertinent to the electrical, structural, acoustics, fluid, heat, and chemical disciplines. You can use these examples as a starting point for your own simulation work by downloading the tutorial model or demo app file and its accompanying instructions.

Search for tutorials and apps relevant to your area of expertise via the Quick Search feature. Note that many of the examples featured here can also be accessed via the Application Libraries that are built into the COMSOL Multiphysics® software and available from the File menu.

This tutorial explores how pulse reverse plating can be used as an additive-free alternative to attenuate small protrusions during copper metal deposition. By matching the process parameters, including the length of the forward and reverse pulses (duty cycles), a bright mirror-like metal ... Read More

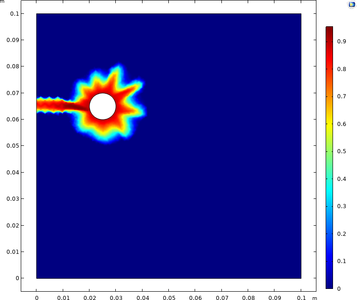

This 2D model demonstrates how to model a galvanic couple in which the corrosion of the anode causes a geometry deformation. The parameter data used is for an Magnesium Alloy (AE44) - mild steel couple in brine solution (salt water). Read More

In small PEM fuel cell systems (in the sub-100 W range) no active devices for cooling or air transport are normally used. This is due to the desire to minimize parasitic power losses from pumps and fans, and to reduce the system complexity, size, and cost. The reactants at the cathode ... Read More

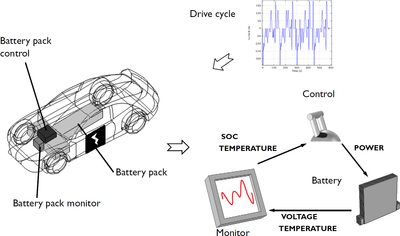

This application shows how a battery cell exposed to a hybrid electric vehicle drive cycle can be investigated with the Lithium-Ion Battery interface in COMSOL. This model predicts the battery behavior to make comparisons of the monitored properties. They can be used to understand the ... Read More

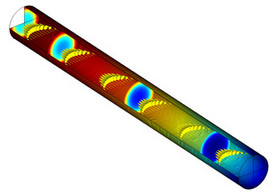

Tubular reactors are often used in continuous large-scale production, for example in the petroleum industry. One key design parameter is the conversion, or the amount of reactant that reacts to form the desired product. In order to achieve high conversion, process engineers optimize the ... Read More

One of the most common reactors in the chemical industry, for use in heterogeneous catalytic processes, is the packed bed reactor. This type of reactor is used both in synthesis as well as in effluent treatment and catalytic combustion. The reactor consists in essence of a container ... Read More

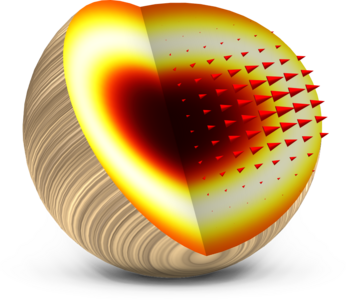

The pyrolysis of a centimeter-sized wood particle presents a fully coupled multiphysics problem with mass transfer, fluid flow, and heat transfer. This example model consists of two parts. The first part demonstrates how to set up a model describing the pyrolysis of a porous, ... Read More

This space-dependent model describes a stirred semibatch reactor used for producing antibody–drug conjugates. The reactor is set up in 3D and the conjugation reactions, turbulent flow, and concentration fields are simulated as functions of time. The resulting yield and drug-to-antibody ... Read More

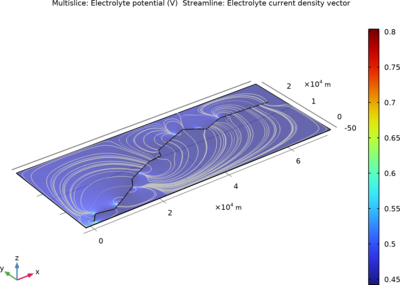

In this example, three parallel pipelines of length 68 km and a horizontal separation distance of 10 m between them are protected against corrosion by an impressed current cathodic protection (ICCP) system using a series of anodes. Each anode is connected to all three pipelines, ... Read More

Oxide jacking is the process by which reinforced concrete cracks, due to the corrosion of the reinforcing rebar rods. The corrosion process causes growth of an oxide layer on the rebar, which in turn causes internal stresses in the concrete. If the corrosion process is allowed to ... Read More