The Application Gallery features COMSOL Multiphysics® tutorial and demo app files pertinent to the electrical, structural, acoustics, fluid, heat, and chemical disciplines. You can use these examples as a starting point for your own simulation work by downloading the tutorial model or demo app file and its accompanying instructions.

Search for tutorials and apps relevant to your area of expertise via the Quick Search feature. Note that many of the examples featured here can also be accessed via the Application Libraries that are built into the COMSOL Multiphysics® software and available from the File menu.

This example demonstrates how to use the Uncertainty Quantification Module by running a series of uncertainty quantification studies for a steel bracket. This type of bracket can be used to install an actuator that is mounted on a pin placed between the two holes in the bracket arms. ... Read More

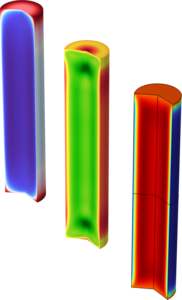

A steel billet is quenched in oil from its austenitic state. A 2D axisymmetric model is used to simulate the coupled problem of austenite decomposition, heat transfer, and solid mechanics. During the quenching process, the austenite decomposes into a combination of ferrite, pearlite, ... Read More

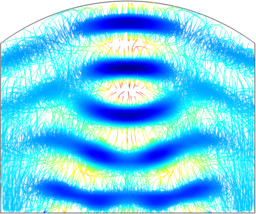

An ultrasonic standing wave levitator, also called acoustic levitator, is a device used for levitating fluid and solid particles in an acoustic field. The standing acoustic waves exert an acoustic radiation force on the particles. The force is a second order effect and stems from a ... Read More

The backward facing step is an interesting case for studying the performance and solution strategy of a turbulence model. In this case, the flow is subjected to a sudden increase of cross-sectional area, resulting in a separation of flow starting at the point of expansion. Spatial ... Read More

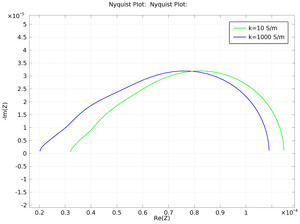

A fuel cell unit cell is modeled using the full Butler-Volmer expression for the anodic and cathodic charge transfer reactions. The anodic and cathodic overpotentials depend on the local ionic and electronic potentials, which are obtained from the charge balance equations for ionic and ... Read More

When anodizing aluminum, the surface is electrochemically altered to form an abrasive and corrosion-resistive Al2O3 film. The electrode kinetics during the process are only marginally affected as the oxide layer grows, so a stationary analysis of the current distribution is sufficient to ... Read More

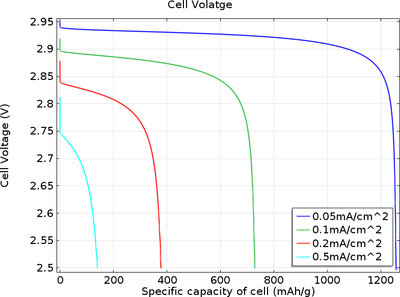

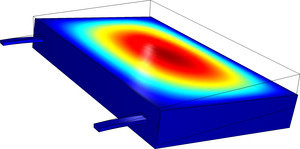

Rechargeable lithium-air batteries have recently attracted great interest mainly due to their high energy density. The theoretical value is about 11400 Wh/kg which is around 10 times greater than the lithium-ion batteries. In this tutorial, discharge of a lithium-air battery is ... Read More

Squeezed-film gas damping is a critical aspect of many MEMS transducers and actuators. In accelerometers, for example, inertia produces a motion that the device detects. A typical structure connects a large proof mass to surrounding structures with elastic beams, which forms a mechanical ... Read More

This model demonstrates how to use the Free Shape Shell feature to increase the stiffness of a shell by deforming its shape. Read More

Differentially pumped vacuum systems use a small orifice or tube to connect two parts of a vacuum system that are at very different pressures. Such systems are necessary when processes run at higher pressures and are monitored by detectors that require UHV for operation. In this model, ... Read More