A Model of Concrete Carbonation Using COMSOL Multiphysics®

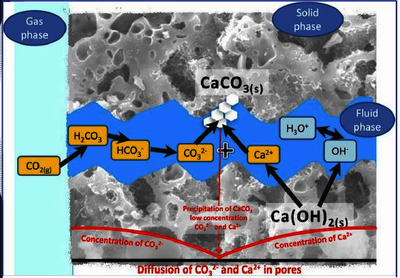

In the construction sector the concrete and the steel bars represent still the key components, although they are very vulnerable by the atmospheric agents, as in the case of their degradation caused by corrosion. The study of the concrete carbonation, due to the CO2 which permeates the porous and fractured structure of the concrete, is a fundamental issue for establishing conditions of the concrete degradation. In the same time the carbonation controls the reinforcing bar corrosion and the durability of the whole civil structure. The value of the concrete carbonation may show existence of corrosion around the reinforcing bar, denote deterioration of the mechanical properties of the material and finally of the structure. Computational modeling and experimental testings of porous materials as the concrete, are both considered very powerful methods for the scientific community. In this work we model the time dependent carbonation process of a concrete by using the Chemical Reaction Engineering Module of Comsol Multiphysics. The carbonation reaction is set up in the Reaction Engineering interface, then we use the Generate Space-Dependent Model feature tool to export the properties to the Transport of Diluted Species physics. The diffusion of the species in the concrete is carried out by considering the concrete as a partially saturated porous media. The porosity modified by the chemical processes is also computed with Comsol Multiphysics using the ODEs and DAEs interface. The numerical results give the carbonation front in time, species concentration (Fig.1) and porosity of the carbonated concrete. The validation of our results is made by comparing them with experimental testings in an accelerated carbonation chamber, accomplished under controlled conditions of relative humidity, CO2 concentration and temperature. The x-ray diffraction measurements, thermo-gravimetric analysis and compression testing of the carbonated concrete samples show the effectiveness of the computational model. The computational results obtained with Comsol Multiphysics are encouraging for a next study which will also include the steel bar corrosion.

Download

- chine__presentation.pdf - 2.29MB

- chine__paper.pdf - 0.61MB

- chine__abstract.pdf - 0.1MB