The Influence of Sensor Technology on the Performance of Acoustic Leak Detection for Water Networks

As water networks around the world age, leakage and water main breaks are becoming an increasing problem. Leakage rates of 10-30% are typical in North America, and most cities suffer from hundreds (or thousands) of water main breaks every year. Echologics has developed the EchoShore permanent leak-monitoring systems to address this problem. These acoustic systems allow utilities to detect and repair leaks as they form, thereby reducing water losses and service disruptions.

The EchoShore-DX system, designed for distribution mains, utilizes a network of mounted sensors installed on fire hydrants. The Echoshore-TX system, for use with transmission mains and critical water supply lines, uses hydrophone sensors which are typically installed in access chambers. When a leak forms, the sound generated by the leak propagates in both directions through the water main and is detected by these acoustic sensors. The performance of these leak-monitoring systems depends primarily on the sensor technology and the degree of sound propagation. The sound propagation is dependent on the pipe material and pipe diameter.

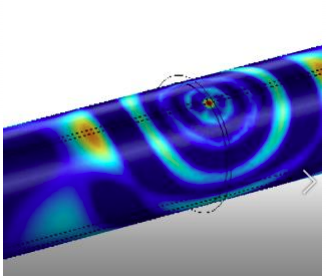

In North America, pipe material varies by region, with the most common materials being cast iron (~30%), ductile iron (~30%) and PVC (~25%). Other materials used include asbestos cement, steel, concrete and HDPE. This study investigates the propagation of sound for different pipe materials and diameters and the response of the pipe to different stimuli. The study also compares the different acoustic sensor technologies: mounted accelerometers, which measure the vibrational response of the pipe, and hydrophones, which measure the pressure variation inside the water column. Sound propagation due to leakage and its detection by acoustic sensors is a Multiphysics problem as the generated wave is coupled between the water column and the pipe wall. In order to account for this acoustic-structure interaction using COMSOL®, both the Acoustics and Structural Mechanics modules were used.

The spectral responses of the pipe wall and in the water column were computed for different known excitations by measuring the respective physical variables of acceleration and pressure. These simulations were performed in order to compare the response in terms of acceleration of the wall, as if measured with mounted sensors, and in terms of pressure variation in the water column, as if measured with hydrophones. Different pipe types, diameters and line pressures were explored.

This paper presents the comparative results for the different leak detection configurations. Results from simulations were compared with experimental results from tests conducted at Echologics’ research facility located in Walkerton, Ontario. This research facility contains more than 2,000 feet of metallic and plastic water mains with diameters ranging from 6-inches to 18-inches. Results from the Comsol simulations were then used to assess the performance of the EchoShore-DX and Echoshore-TX systems.

Download

- S_Perrier-Echologics.pdf - 1.4MB