COMSOL Conference 2025 Proceedings

Collection of Papers, Posters, and Slideshows Accepted by the Program Committee

At the COMSOL Conference 2025, engineers, researchers, and scientists from around the globe showcased their use of modeling and simulation across all major industries and in academia. Use the Quick Search tool to find a specific presentation or filter by topic or event location.

ISBN: 978-1-7364524-3-1

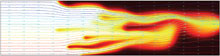

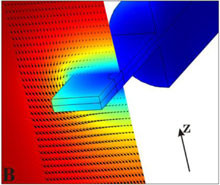

Viscous fingering is a topic of interest since the beginning of computational fluid dynamics. Here we focus on the classical constellation of miscible displacement, as it has been investigated in Hele-Shaw cells. A temperature or salinity front is entering with a fluid that has a ... Read More

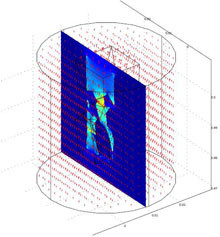

In the present study we determined the relative conductivities and permittivities of fresh cortical and cancellous bone measuring human femoral heads in different slices of 1 mm thickness. The identified conductivities of human trabecular bone are used for the electromagnetic field ... Read More

For medical diagnostic purposes there is an increasing need for non- (or minimal) invasive techniques to measure all kinds of parameters that can provide insight in the functioning of cells, organs or organ systems. Currently, Impedance Cardiography (ICG) is used for measurements of the ... Read More

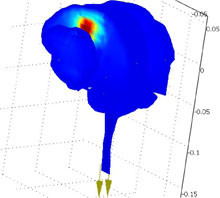

Brain edema is one of the most common consequences of serious traumatic brain injuries which is usually accompanied with increased Intracranial Pressure (ICP) due to water content increment. A three dimensional finite element model of brain edema is used to study intracranial pressure in ... Read More

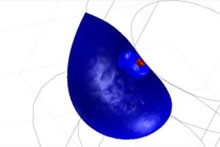

This work presents new Fluid-Structure Interaction (FSI) models in both 2D and 3D of the effect of using vascular stents as treatment of cerebral berry aneurysms. The stent is positioned inside the cerebral artery covering the neck of the aneurysm. The stent is expected to alter the ... Read More

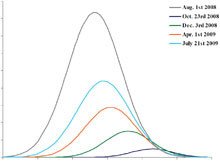

During cryopreservation of human embryos, ice crystal formation in the embryos or in surrounding media may cause cryodamage to them and can be lethal. A strategy to avoid this is the vitrification procedure when the embryo and the surrounding medium undergo the transition to glassy state ... Read More

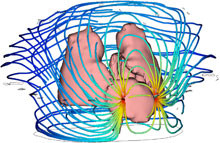

In this paper, we present a mathematical model of contractile elastic solids meant to simulate various districts of the cardiovascular system, and based on the concepts of active deformation and embedded muscle fibres. Specifically, here we deal with the modeling of the gross mechanics ... Read More

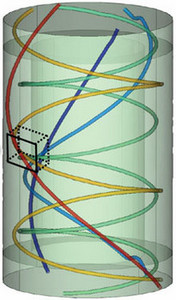

Natural groundwater flow can increase the efficiency of geothermal system. But groundwater flow is not available everywhere. A patented new idea is to use air injection well to create artificial flow in sandy or gritty soils. The governing equations of fluid flow and heat transfer ... Read More

The bentonite barrier is an essential part of a safe spent fuel repository in granitic bedrock. In this work COMSOL Multiphysics® is used in modelling the Thermal (T), Hydrological (H), Mechanical (M) and Chemical (C) phenomena and processes taking place in a bentonite buffer. Special ... Read More

Modeling soil water dynamics requires an accurate description of soil hydraulic properties, i.e. the retention and hydraulic conductivity functions. Generally, these functions are assumed to be unchanged over time in most simulation studies. In this paper, we implemented temporal changes ... Read More