See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Electrochemical flow cells have found widespread use in analytical chemistry due to their short response time, high sensitivity and selectivity. The geometrical flexibility and therefore, the ease of coupling the electrochemical to other experimental techniques has attracted considerable ... Read More

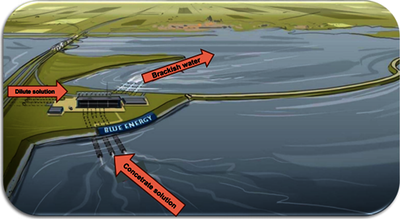

Salinity gradient represents an interesting renewable energy source. Reverse ElectroDialysis (RED) is an ion exchange membrane-based process that convert directly the salinity gradient energy into electric current. Thereby, two solutions at different concentrations are fed into two ... Read More

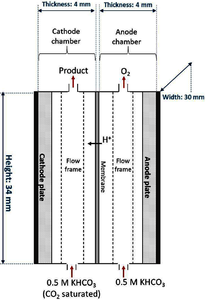

Carbon dioxide levels are increasing faster than in hundreds of thousands of years due to fossil fuels burning. A serious worldwide interest is growing towards the field of CO2 valorization as a step in transitioning away from fossil fuel economy at the same time of decreasing CO2 ... Read More

Abstract: A 3.2V/10Ah LFP aluminum-laminated batteries are chosen as the target of the present study. A three-dimensional thermal simulation model is established based on finite element theory and proceeding from the internal heat generation of the battery[13]. The study illustrates a ... Read More

The reaction current density is an important process parameter of lithium-ion battery, significantly influencing its electrochemical performance. In this study, aimed at the discharge process of lithium-ion power battery, an electrochemical-thermal model was established to analyze the ... Read More

A 3D (three-dimensional) model of a vanadium redox flow battery (VRFB) with interdigitated flow channel design is proposed to study the distributions of fluid pressure, electric potential, current density and over-potential during operation. The performance of a VRFB with and without ... Read More

A new method is proposed to study battery thermal behavior under nature convection condition, especially focusing on temperature rising and inhomogeneity of battery. Using porous electrode theory, an electrochemical and homogenization heat source thermal coupling model and an ... Read More

Battery grids are critical system used in automobile, renewable energy, medical devices and mobile phones. Research efforts are directed to increase energy density, longevity and reduce the cost. This paper is related to computational optimisation of lead acid battery for efficiency and ... Read More

A lithium-ion battery comprises of two intercalating electrodes separated by a membrane, sandwiched between aluminum and copper current collecting plates. The battery performance depends upon several parameters and its operating conditions. In this work we developed a model for a lithium ... Read More

The performance of a PEMFC depends on several factors, including the flow inside gas channels. Low gas velocity inside the channel can make water management more difficult, possibly causing water to accumulate and condense in certain regions of the cell. In the present work, COMSOL ... Read More