See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Introduction: After more than 20 years of experience in EV applications, the sodium nickel chloride technology is fully mature for large scale energy storage. Early on, mathematical modeling of Na-MCl2 cell (M standing for Fe or Ni) has attracted attention to help identifying predominant ... Read More

The future development of electric vehicles is now strictly linked with their batteries. In parallel of the actual research focused on the development of new materials and increase their performances in terms of energy, power, cost, durability and weight, it is necessary to develop ... Read More

Unmanned aerial vehicles (UAVs) have recently received great interest due to their great potential in both military and civil applications [1-4]. Testing and construction of UAVs is expensive and time consuming and a simulation approach can help to reduce cost for both design and tests. ... Read More

Two Anode Surface processes are examined : Formation of Solid Electrolyte Interphase (SEI) and heating due to Shuttle Current. During charging, higher order sulfur species are reduced at the anode surface, while they are concurrently being oxidized at the cathode. This leads to the ... Read More

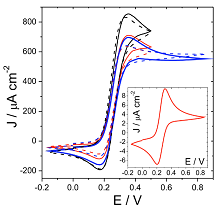

The microband design of microelectrodes is a cost-effective and easily-fabricated compromise combining convergent mass transport, due to microscale width as a critical dimension, and high output currents due to the macroscopic length. Among the various techniques available for microband ... Read More

Numerical simulation can be advantageously employed to predict the main cell features (e.g., the reaction rate distribution on the electrodes, the cell voltage, or the electrolyte temperature) in order to optimize the design and operational conditions of the process. In this poster, we ... Read More

The poster presents a methodology to account for thermal effects on battery cells to improve the typical thermal performances in a pack through heating calculations generally performed under the operating condition assumption. The aim is to analyze the issues based on battery thermo ... Read More

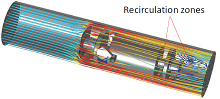

PEM Fuel Cells’ durability and performance can be increased using an ejector based hydrogen recirculation system. In this work, a CFD model has been implemented to simulate the flow within an ejector used to recirculate hydrogen in PEM Fuel Cell systems. The model has been validated ... Read More

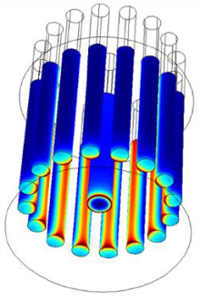

In the nuclear fuel cycle, fluorine is produced by the electrolysis of the molten salt KF-2HF. It is a complex process to study since hydrofluoric acid and fluorine are hazardous and highly corrosive. A 3D-model of a lab-scale fluorine electrolysis cell has been developed to increase ... Read More

Aqueous based copper electroplating seems the most reliable, flexible, cost effective method to create a copper layer on stainless steel coupler devices; this however, doesn’t imply a straightforward application, as subcomponents geometry is complex and tolerances are tight. At CERN, two ... Read More