See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

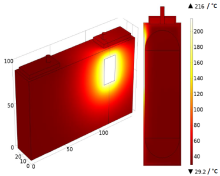

A thermo-physical 3D model of a commercial Li-ion battery was developed and validated. Visualization of the temperature distributions inside a Li-ion cell during cell stacking processes were simulated. Critical temperature levels depend on position, duration and intensity of the thermal ... Read More

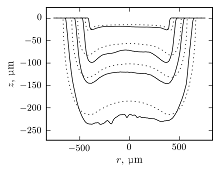

Primary current distribution model for anodization of low-doped p-type silicon through a circular opening in frontside insulating mask is developed. The model is applied in two regimes of the process – pore formation and electropolishing – by definition of current density dependent ... Read More

A thermal model to predict the heat generation during the charge and discharge of a battery pack is an essential tool to manage the thermal behavior, performance and life of the batteries. In this work, a battery cell is modeled in COMSOL Multiphysics® using the Batteries and Fuel Cells ... Read More

A multilayer polymer coating is applied to carbon steel pipelines installed in the sea to protect against corrosion and to insulate to maintain the temperature. For field joint coatings, both thermosets (like polyurethane) and semi-crystalline thermoplastics (like polypropylene) are ... Read More

Rechargeable batteries solve electrification and communication problems. As examples, hybrid battery-diesel generator power supplies efficiently power cell towers in remote locations, detached from the power grid. Large battery banks are used to load level user power requirements, ... Read More

When it comes to study the behavior of the secondary batteries, physics-based models are more representative of the real behaviour than equivalent circuit models, especially for the estimation of the life and capacity fading. On the other hand, the complexity and computational cost of ... Read More

A fuel cell is an efficient and clean alternative power source of energy. Alkaline anion exchange membrane (AAEM) fuel cells are one in which conduction of oH- (hydroxyl ion) take place. The advantages of using alkaline fuel cells over proton exchange membrane fuel cells is that ... Read More

Introduction: Recently, Li-ion battery is being widely used as power source for various applications from electronic gadgets to automotive industry. The performance and cycle life of Li-ion battery are becoming gradually important issues as the applications are shifting from small scale ... Read More

Multi-Scale and Multi-Dimensional (MSMD) modeling approaches have been proposed to simulate the thermal, electrical distributions and concentration behaviors of large size pouch cell. This approach is based on coupling of the energy balance with the Newman’s electrode model. Newman’s 1D ... Read More

The purpose of this work is to show whether an important difference in Lithium solid concentration and electrolyte concentration can be observed in a Lithium-ion battery model, when considering either the Butler-Volmer kinetics or the Tafel kinetics for describing the electrode kinetics ... Read More