See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

The water storage reservoir at the WTP Noardburgum is used to even out demand and supply and ensure a stable drinking water production capacity. At the moment the rectangular reservoir has a single pipeline which serves as an inlet during the fill cycle and as an outlet during the draw ... Read More

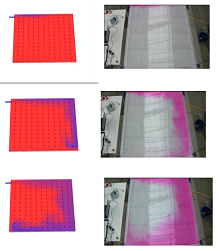

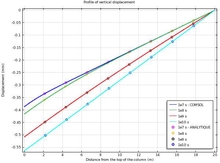

The long-term behaviour of the underground excavations is a social and economic challenge particularly in the contexts of post-mining or radioactive waste storage. Numerical modelings are currently used to understand and forecast the complex behaviour of rock mass around the underground ... Read More

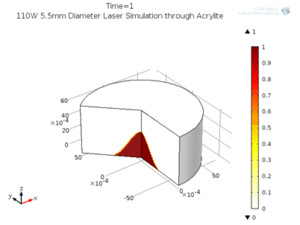

In this paper we present a transient numerical model of the heat transfer and thermochemical damage evolution in an IR translucent material using COMSOL Multiphysics. The model is evaluated using literature supplied and experimentally determined material properties for carbon black laden ... Read More

Dr. R. N Singh is currently a INSA Senior Scientist. Prior to this appointment, he was a CSIR Emeritus Scientist at the National Geophysical Research Institute (NGRI), Hyderabad. He has been the Scientist-in-Charge of CSIR Centre of Mathematical Modeling and Computer Simulation, ... Read More

UCG is a process which converts coal to syn gas at the underground coal seam itself. UCG can help meeting the rising energy demand by utilizing coal resources that otherwise would be too deep, or of poor quality, or simply not economical to mine. As UCG takes place, a cavity is formed ... Read More

We use finite elements simulations in order to study the fluid flow behavior in a chamber of a preconcentrator. We realized that most part of the fluid does not affect our preconcentrator because it is going out the chamber at high distance above it and parallel to the preconcentrator. ... Read More

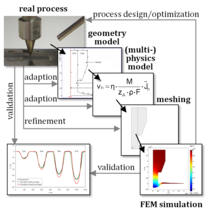

Electrochemical Machining is a potential procedure for micro manufacturing technology. Especially the absence of machining forces makes it advantageous for processing metals with high hardness and for the generation of complicated geometries. Applying a closed electrolytic free jet (Jet ... Read More

In The Netherlands rising dampness problems due to flooding of rivers and high groundwater levels form an essential treat for monumental buildings and heritage. A number of cases exists where rising dampness problems lead to the deterioration of wall finishes but also of valuable wall ... Read More

A lot of techniques are developed to treat soils polluted by hydrocarbons pollutants: incineration, thermal treatment, extraction, chemical oxidation, bioremediation… Some of these techniques are very energy consuming (incineration, thermal treatment…) and often need a subsequent ... Read More

The principle of electrochemical machining (ECM) is the anodic dissolution of a metallic workpiece at the interface to a liquid ionic conductor under the influence of electric charge transport. This erosion principle works independently from the mechanical hardness of the workpiece and ... Read More