See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

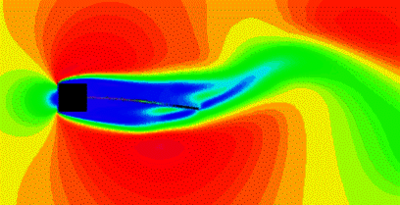

Fluid-structure interaction (FSI) refers to a class of problems in which the motions of fluid and solid are coupled. FSI is of great significance in many applications such as aero-elasticity, biomechanics, and design of various engineering systems. Typically, the multiphysics involved in ... Read More

The production model in the COMSOL Multiphysics® software makes use of the most up-to-date PIE data, material property inputs, and modeling methodology. The fully coupled thermo-mechanical equations are solved over the entire domain, significantly increasing the degrees of freedom ... Read More

Graphene, a single layer of carbon atoms, has demonstrated extremely high electric and thermal conductivities, tensile strength, and is therefore an exciting novel building block in the world of 2D flexible electronics. We propose the integration of graphene with MEMS devices to ... Read More

Previous to the present work, a formal calculation was approved [1,2] to support the operation of the High Flux Isotope Reactor (HFIR) Horizontal Beam-Tube 1 of 4 (HB-1). The present calculation [3,4] repeats the previous work using COMSOL Multiphysics® software and extends the analysis ... Read More

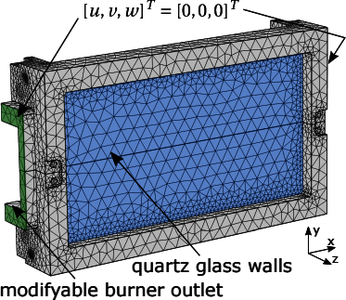

Enhanced operational flexibility and low levels of pollutant emissions are achieved with a sequential arrangement of premixed combustion stages in gas turbines for power generation. In the second – reheat – combustion stage, hot flue gases of approximately 1500K are enriched with fuel ... Read More

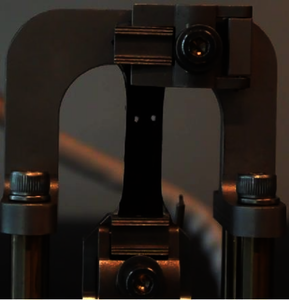

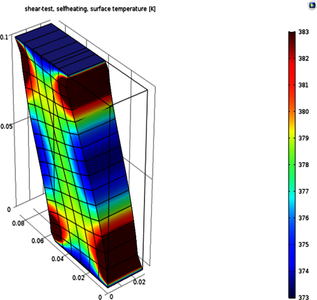

The objective of this study is to acquire a full characterization of a hyper-elastic material. The process is realized by performing a Dynamic Mechanical Analysis (DMA) with a viscoelastic material, which is extended by image processing algorithms in order to measure the changing ... Read More

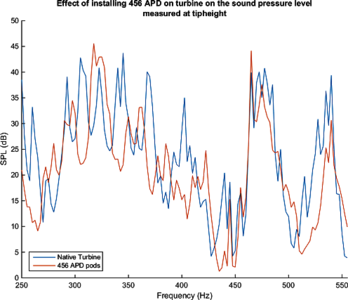

Tonal noise from wind turbines can have effects on neighboring residences and its emission can result in strong regulatory penalties that can include the closure of wind farms. The authors present a model of a new broadband damping approach where containers filled with EniDamp™, an ... Read More

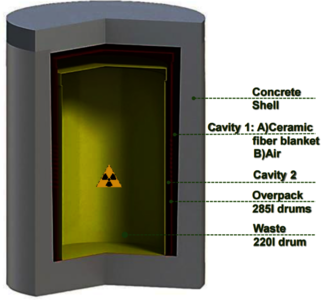

Confinement systems for nuclear waste are usually designed to perform and ensure safety in view of all the assumed design basis events, including fires. Considering waste typology and radioactivity, the goal of the confinement system design is to protect the content of the steel drums ... Read More

Using COMSOL Multiphysics® software, a new model was implemented with the Physics Builder functionality, which provides a thermomechanical coupling. It consists of two independent physics interfaces, one for the mechanical, viscoelastic behavior and one for the heat transfer. With the ... Read More

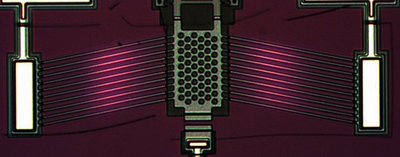

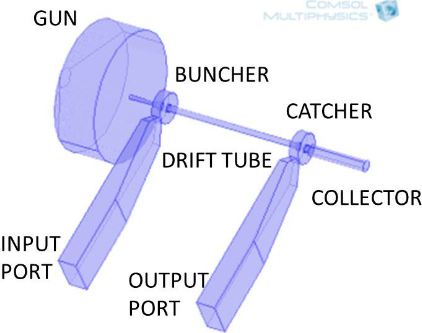

The multiphysics analysis of a 130 GHz klystron is described in this paper. Critical quantities are exposed to multiple physics effects acting on narrow dimensions modified by power dissipations. The proposed device uses an integrated injection/bunching section described in last COMSOL ... Read More