See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

This paper demonstrates experience of using the COMSOL Multiphysics® transport phenomena models in design practice, particularly at the early stage of design when there is might be too many possible design suggestions relying on the shell balance equations, and engineering intuition. ... Read More

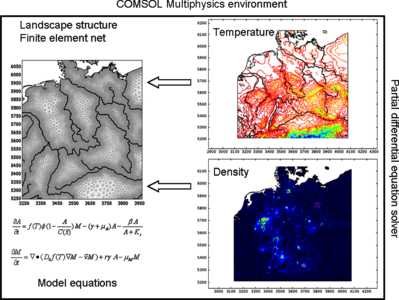

Mosquito- borne diseases are resurgent due to insecticide resistance. In this paper a model is presented combining insect dispersal and population genetics for the simulation of the emergence of pesticide resistance in dependence on management practices. Dispersal of populations and ... Read More

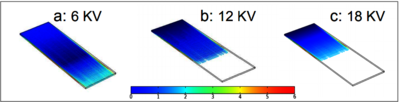

The good electrical, thermal, mechanical and chemical properties of solid organic dielectrics, such as PTFE, predestine them as good candidates for the electrical insulation of transport devices and systems. In the particular case of power converters involved in the future hybrid and ... Read More

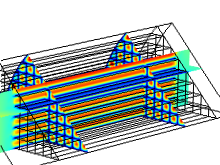

Electrostatic precipitation is an extremely efficient way of filtering fine particles from the airstream. Electrostatic precipitators (ESPs) can control airborne emission without significantly slowing down the rate of flow, because of the low pressure drop across this type of filters. A ... Read More

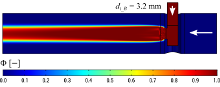

Recently, hydrogen is widely used as environmental energy and high energy content. The hydrogen is mainly produced by water gas shift reaction(WGSR) from coal to hydrogen process in Integrated Gasification Combined Cycle(IGCC) plant. WGSR, well known for hydrogen production, is a ... Read More

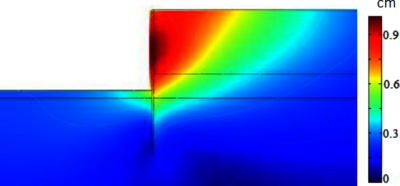

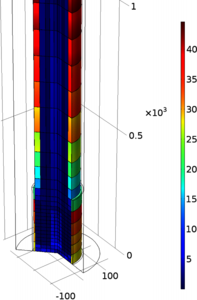

Deformation prediction is an important part of the structure stability analysis. However, the deformation of bank protection structure which is affected by many factors, such as structural stiffness, earth pressure and hydrostatic pressure. It contains a complex mechanical process, which ... Read More

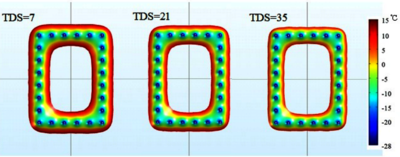

With the extensive application of ground freezing method in coastal areas, the groundwater environment during ground freezing has been changed. Especially in seawater intrusion areas, groundwater salinity is high (even salinity equivalent to sea water (ca. 35g/L)). Engineering experience ... Read More

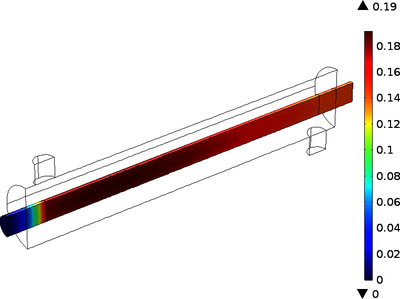

In order to improve hydrogen production in an ethanol reformer it is needed to understand what happens inside it. Also, a simulated model can simulate different work conditions avoiding the necessity of doing tons of experiments. A 3D computational fluid dynamics simulation study of ... Read More

Two-component adhesives are commonly used for sealing and joining in transport applications for mechanically highly stressed connections. At the Chemnitz University of Technology an innovative system technology for the user-friendly, wireless and energy-efficient processing of two ... Read More

Plant roots have an outstanding ability to grow in the direction of gravity or nutrients. Bending of the root tip in the preferred direction is achieved by asymmetric cell growth on the opposite sides of the root, dictated by asymmetrical distribution of the hormone auxin. Increase in ... Read More