See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

全球能源需求的不断增长,以及解决与日俱增的环境污染和气候变化的迫切需求,都在不断地刺激着更有效的能源获取技术。虽然在盐度梯度中发现了可提取的能量,即通过开发自然水生系统来获取蓝色能量(blue energy),但单位面积上的能量功率(~5 W/m2)并不高。为了进一步提高能量转化效率,就不能单纯依靠吉布斯自由能(Gibbs free energy),还应该充分利用磁场。故,探究磁场对带电纳米孔道中阴阳离子输运的影响,来启发实验取得进一步的突破。 应用了AC/DC模块和化学物质传递模块中的稀物质传递,以及对传递属性中的弱表达式进行修改。从而实现磁场 ... Read More

通讯作者:衡益,邮箱:hengyi@mail.sysu.edu.cn 热传导反问题已广泛应用于如航空航天工程、机械加工、化学工程、冶金等工程领域。数学不适定性使其很难快速稳定求解。我们近年来进行了一系列相关研究[1-5]。与传统的基于优化的方法不同,本工作针对薄板上三维瞬态热传导反问题,即通过薄板加热面上的温度测量信息估算上表面的瞬态热流分布,提出了两步直接法。基本思路是通过重构Dirichlet边界条件将该反问题转化为易于求解的正问题,以获得近似解。此外,我们提出了基于后验误差的时空自适应网格细化离散策略进一步提高计算效率。本工作采用COMSOL ... Read More

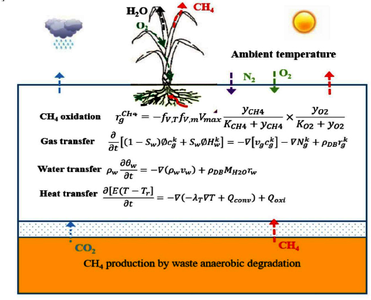

目前,很少有模型来描绘植被通对填埋场覆盖土甲烷传输、氧化和释放的影响。本研究的目的是利用模型分析的方法来分析植被对填埋场覆盖体甲烷传输、氧化和释放的影响。模型主要考察了植物关键生理特性如根结构、植物释氧强度、根长度、植物蒸腾速率以及环境因素如覆盖土初始含水率、环境温度等对甲烷氧化的影响。模型研究结果将有助于理解填埋场植被覆盖区甲烷释放机制以及选择合理填埋场管理方式减少温室气体排放。 本研究运用多孔介质稀物质传递、Richarcd 方程、达西定律、热对流等模块分析了植被覆盖条件下填埋场覆盖土中水、热、气传输耦合甲烷氧化 ... Read More

Magnesium hydride (MgH2) has been one of the most promising hydrogen storage methods that can be applied to commercial hydrogen energy systems due to magnesium’s safety, low cost, and excellent storage capacity for hydrogen, compared to other reversible metal hydrides. But hydrogen ... Read More

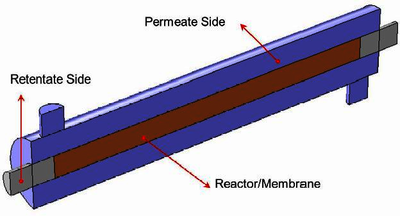

Hydrogen production by water gas shift reaction(WGSR) in Integrated Gasification Combined Cycle (IGCC) plant is the most popular process in the world. Traditional hydrogen production process by WGSR is consist of two processes due to its’ considerable exothermic equilibrium reaction ; ... Read More

The anode baking process has gained significant attention since the 1980s due to its importance in Aluminium industry. A good anode baking process strives to achieve multiple goals including reduction of NOx from emissions. NOx generation is mainly due to the high-temperature ... Read More

Enhanced oil recovery (EOR) is expanding worldwide to produce more oil from the existing reservoirs to fulfil the demand of the global consumption, which increases on yearly basis. Thermal methods like steam injection and its variations are the most famous methods applied in heavy oil ... Read More

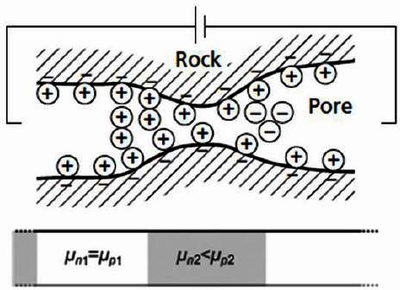

Spectral Induced Polarization (SIP) is a geophysical technique that measures the frequency dependence of the electrical conductivity of a material. The potential of using SIP to predict the hydraulic conductivity of the ground has been investigated since 1950s. However, the dependency of ... Read More

The dissolution behaviour of powders is an important factor when evaluating their applicability for customer and industrial use. The dissolution speed of a powder can be influenced by a number of parameters. Important parameters are particle size, porosity and powder composition amongst ... Read More

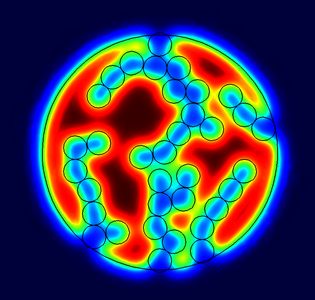

A large variety of applications in environmental, petroleum and chemical engineering involve multiphase flow. Examples include fluid flow in presence of bubbles/droplets, phase separation of immiscible fluids and wetting phenomena. Multiphase flow is characterised by the presence of an ... Read More