Press Release

COMSOL OY

Tekniikantie 4 A

02150 ESPOO

Finland

Phone: +358 9 2510 400

View on a map

Editor Contact:

Jukka Tarvo

jukka@comsol.com

New Inverse Design Method Accelerates Fuel Cell Development

At Toyota Research Institute of North America, fuel cell researchers are developing a simulation-driven methodology that brings the automaker closer to its vision of creating a global "hydrogen society".

BURLINGTON, MA (MAY 23, 2023) — Toyota Research Institute of North America (TRINA) has developed a new simulation-driven inverse design methodology to accelerate the research and development process for fuel cell flow field plates. The methodology sets key performance objectives and directs algorithms to generate structural flow field forms that fulfill those objectives. The TRINA team engineered this approach by integrating the COMSOL Multiphysics® software into its inverse design workflow.

"We think that the inverse design approach can revolutionize current design practice," says Yuqing Zhou, a research scientist at TRINA. "We are enabling the next step in a long journey, even though we cannot know exactly where that journey will lead." The team at TRINA applied its method to the design of flow field microchannel plates, which direct the movement of fluid reactants in microreactors like hydrogen–oxygen fuel cells.

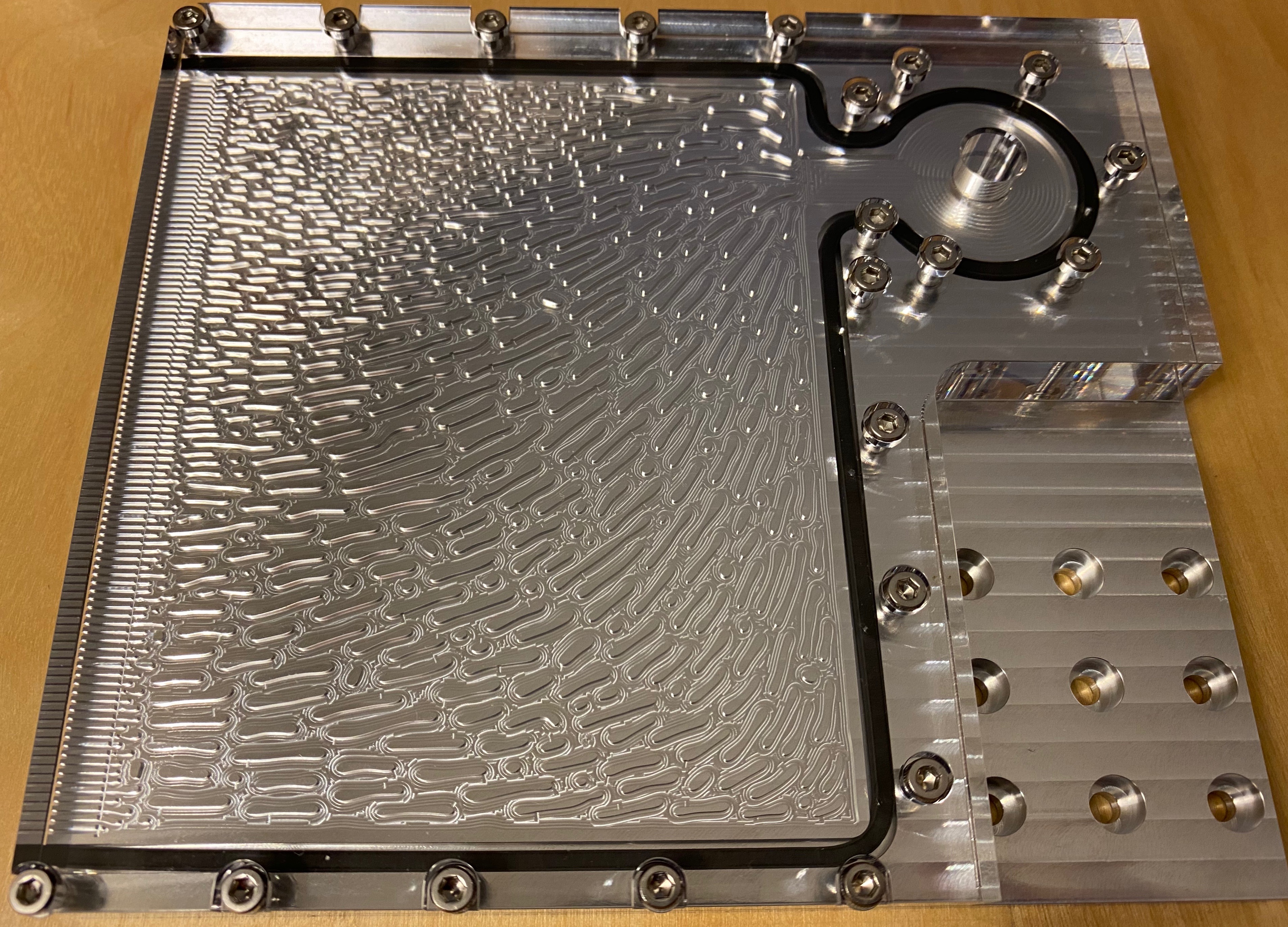

A metal flow field plate prototype based on one of the TRINA team's generated designs.

TRINA is part of a large network of Toyota R&D teams that are working toward the development of a “hydrogen society”, where fossil fuel-burning engines, heating systems, and generators would be replaced by fuel cells that extract electric current from hydrogen.

"Fuel cell technology has the potential to provide clean energy globally," says Margaret Lemus, VP of Marketing at COMSOL. "To achieve this, the technology needs to become more efficient, and optimizing the designs is an important step. It's exciting to see how simulation empowers researchers to explore different options and make informed decisions that can lead to more efficient fuel cell designs."

Optimizing Designs for Flow, Reaction, or Both

During their research, Zhou and his colleagues recognized that they needed to optimize their design process before they could optimize their designs. "We were seeking an efficient way of approximating what a more complex simulation would show. We have sacrificed some modeling complexity, which actually enables us to explore more elaborate designs in less time," says Zhou.

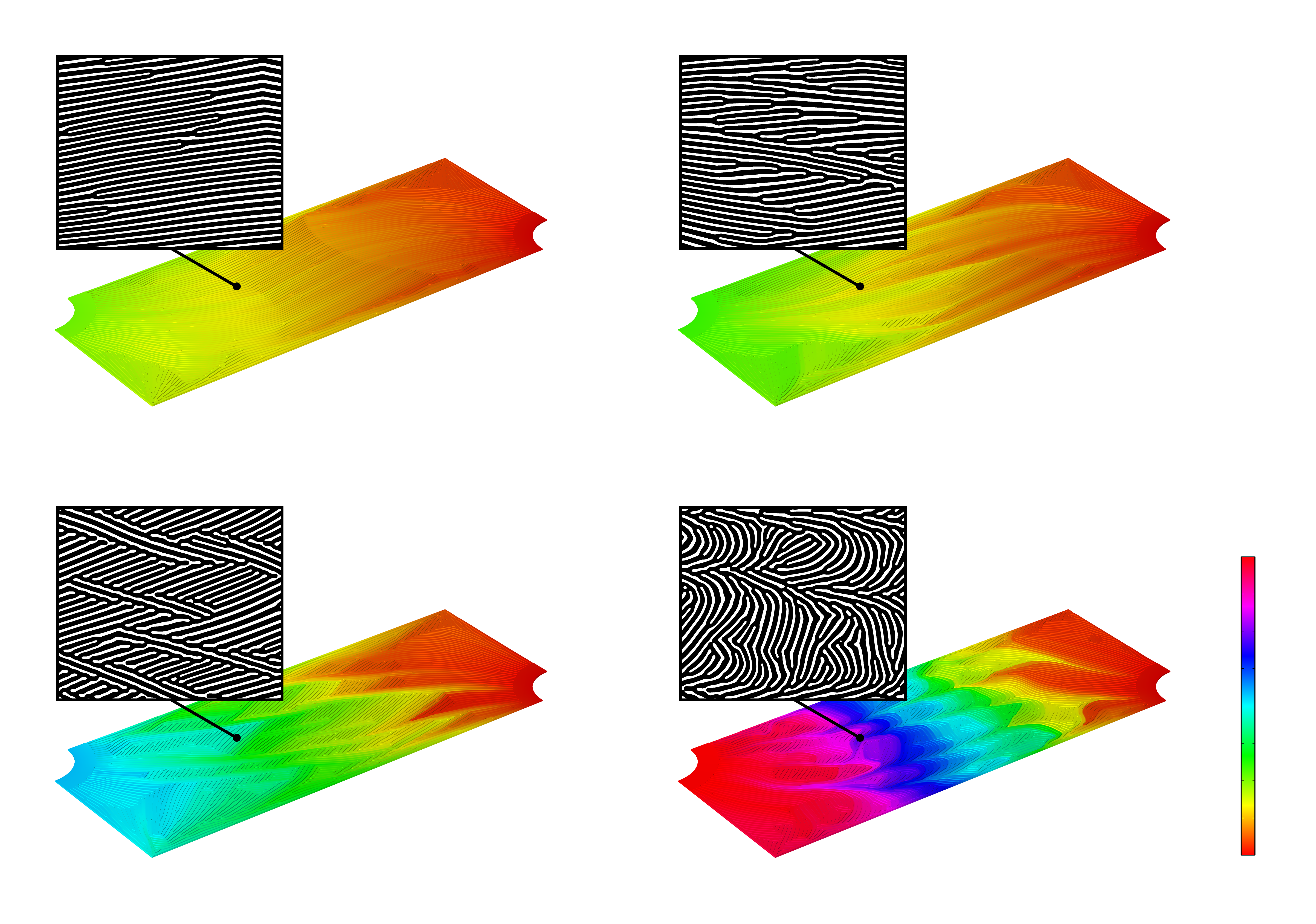

When their design was optimized for fluid flow, the generated microchannel paths were straight and parallel, with little side branching. When the weighting factors in the objective function were adjusted to prioritize reaction uniformity, the method generated intricate microchannel forms.

Simulation results from the TRINA team's model, showing the pressure distributions resulting from four different microchannel flow field designs.

In a research paper, published in Chemical Engineering Journal, the TRINA team also notes that some have previously experimented with natural-looking, fractal, or hierarchical forms selected a priori for flow field channels. About TRINA's own research, Zhou says, “This is the first time that such large-scale branching flow fields have been discovered using an inverse design approach without assuming prescribed layouts.”

Toyota's journey to developing fuel cells is discussed in further detail in the COMSOL User Story Gallery and in a keynote talk from COMSOL Day: Batteries & Fuel Cells.

In addition, you can learn more about the TRINA team here and read its research paper published in Chemical Engineering Journal.

About COMSOL

COMSOL is a global provider of simulation software for product design and research to technical enterprises, research labs, and universities. Its COMSOL Multiphysics® product is an integrated software environment for creating physics-based models and simulation apps. A particular strength is its ability to account for coupled or multiphysics phenomena. Add-on products expand the simulation platform for electromagnetics, structural, acoustics, fluid flow, heat transfer, and chemical applications. Interfacing tools enable the integration of COMSOL Multiphysics® simulations with all major technical computing and CAD tools on the CAE market. Simulation experts rely on COMSOL Compiler™ and COMSOL Server™ to deploy applications to their design teams, manufacturing departments, test laboratories, and customers throughout the world. Founded in 1986, COMSOL has 17 offices worldwide and extends its reach with a network of distributors.