In accordance with our Quality Policy, COMSOL maintains a library of hundreds of documented model examples that are regularly tested against the latest version of the COMSOL Multiphysics® software, including benchmark problems from ASME and NAFEMS, as well as TEAM problems.

Our Verification and Validation (V&V) test suite provides consistently accurate solutions that are compared against analytical results and established benchmark data. The documented models below are part of the COMSOL Multiphysics® software’s built-in Application Libraries. They include reference values and sources for a wide range of benchmarks, as well as step-by-step instructions to reproduce the expected results on your own computer. You can use these models not only to document your software quality assurance (SQA) and numerical code verification (NCV) efforts, but also as part of an in-house training program.

In this example, the External Stress feature in the Solid Mechanics interface is used to provide the material model with the nonsymmetric stress required in the design of an elastic invisibility cloak. The cloak is a domain with special material properties aimed at shielding a region of ... Read More

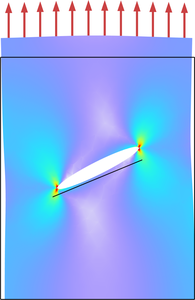

This example reproduces a NAFEMS benchmark in which a plate with an angle crack is subjected to tensile loading. The J-integral is calculated and the stress intensity factors for Mode I and Mode II are compared to the benchmark results for several crack angles. Read More

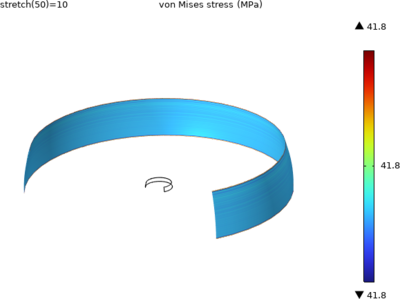

This version of the balloon inflation example demonstrates how the Shell and Membrane interfaces can be used to model thin structures made of hyperelastic materials. The example is identical to the Model Library model 'Inflation of a spherical rubber balloon', except that the Membrane ... Read More

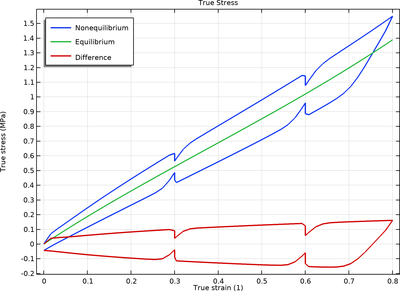

In this example, the Bergstrom–Boyce material model is used to capture the nonequilibrium behavior of carbon-black-filled chloroprene rubber under a strain history that alternates compression with relaxation. Results are verified against experimental and numerical results taken from ... Read More

In this example, learn how to model two rotors connected by a spline coupling. The first rotor is a fixed cantilevered rotor and the second rotor is supported. The model assumes that only translational motion is coupled between the rotors through the coupling, while the rotations of both ... Read More

Isotropic compression is a common material test in soil mechanics. The modified Cam-Clay (MCC) model describes the relation between the void ratio and the logarithm of the pressure. In this example, a cylindrical soil sample under isotropic compression is simulated. It is verified that, ... Read More

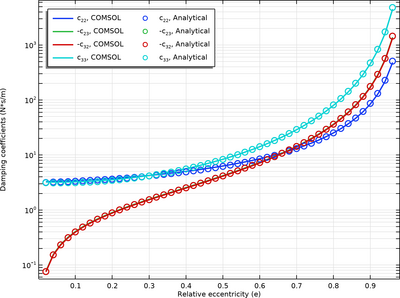

Squeeze film dampers are components that provide additional damping to rotating machines. To simplify the modeling of a rotor assembly, squeeze film dampers are modeled in terms of their damping coefficients which are a functions of the journal location in the damper. This model computes ... Read More

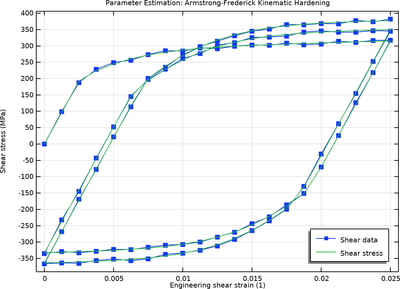

This tutorial model demonstrates how to estimate the material parameters of a combined hardening elastoplastic material model given cyclic shear data. Read More

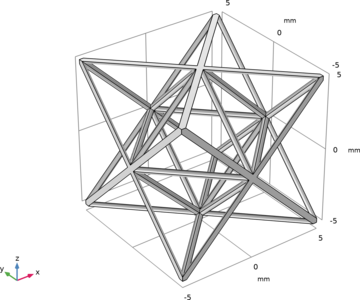

Lattice materials enable the creation of advanced additive manufacturing materials with customized mechanical properties. At the macroscopic level, these heterogeneous materials can be modeled as homogeneous materials. Homogenization techniques can accurately determine the material's ... Read More

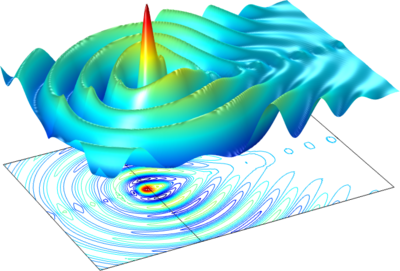

This is a benchmark model for the linearized Euler interface of the Acoustics Module. The model is from the NASA "Fourth Computational Aeroacoustics (CAA) Workshop on Benchmark Problems (2004)". The model results are compared to an analytical solution by Agarwal et al. (AIAA Vol. 42, No. ... Read More