In accordance with our Quality Policy, COMSOL maintains a library of hundreds of documented model examples that are regularly tested against the latest version of the COMSOL Multiphysics® software, including benchmark problems from ASME and NAFEMS, as well as TEAM problems.

Our Verification and Validation (V&V) test suite provides consistently accurate solutions that are compared against analytical results and established benchmark data. The documented models below are part of the COMSOL Multiphysics® software’s built-in Application Libraries. They include reference values and sources for a wide range of benchmarks, as well as step-by-step instructions to reproduce the expected results on your own computer. You can use these models not only to document your software quality assurance (SQA) and numerical code verification (NCV) efforts, but also as part of an in-house training program.

In this model, two flat end mirrors are placed at a distance and a spherical lens is inserted in the middle of the cavity. A ray is released from a point inside the cavity. Then the ray is traced for a predefined time period that is sufficiently long. Ray tracing continues until the ... Read More

For slender structures, buckling is a catastrophic instability if the service load is above the critical limit. For such structures, it can be important to study the behavior of the structure beyond the critical buckling load, which is known as postbuckling analysis. Tracing the ... Read More

In this example, the External Stress feature in the Solid Mechanics interface is used to provide the material model with the nonsymmetric stress required in the design of an elastic invisibility cloak. The cloak is a domain with special material properties aimed at shielding a region of ... Read More

This model simulates the flow through a uniform inclined screen using the Screen feature in Single-Phase Flow physics and compares the results with an analytic solution. Read More

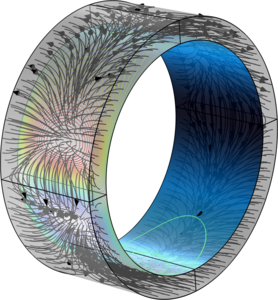

This example describes how to simulate the self-lubricating phenomenon of a liquid lubricant in a journal bearing. A porous bushing is press-fitted to a bearing and saturated with a lubricant. It acts as a reservoir for the redistribution of the thin film of lubricant between regions of ... Read More

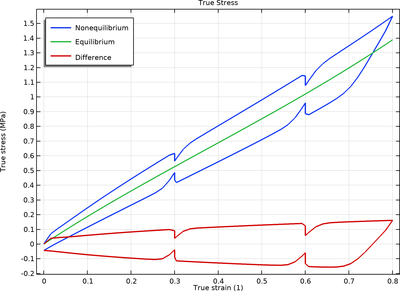

In this example, the Bergstrom–Boyce material model is used to capture the nonequilibrium behavior of carbon-black-filled chloroprene rubber under a strain history that alternates compression with relaxation. Results are verified against experimental and numerical results taken from ... Read More

In this example, learn how to model two rotors connected by a spline coupling. The first rotor is a fixed cantilevered rotor and the second rotor is supported. The model assumes that only translational motion is coupled between the rotors through the coupling, while the rotations of both ... Read More

Whenever dimensions in waveguides become small compared to the viscous and thermal boundary layers it is necessary to model acoustics using thermoacoustics. In the present model the thermoacoustic wave field in a shallow uniform waveguide is modeled and compared to an analytical solution. Read More

In this tutorial model, the far-field radiation pattern of a dipole antenna is computed in a 3D model component. Then, in a separate 3D model component, a ray is released using the far-field radiation pattern to initialize the ray's intensity, polarization, and phase. Read More

Real reactors can be modeled as combinations of ideal reactors. In this example the so-called "Dead zone model" is utilized. Two ideal CSTRs with interchange are set up to model the real reactor. One CSTR represents the highly agitated region and the other the less agitated region. For ... Read More