See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

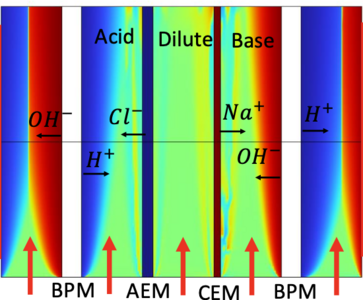

A CO2 direct ocean capture system exploiting bipolar membrane (BPM) electrodialysis, gas-liquid contacter and pH-swing of the dissolved inorganic carbon species is designed for efficient and effective CO2 capture. COMSOL Multiphysics was used to study the BPM electrodialysis and CO2 ... Read More

Spinal cord injury triggers an initial inflammatory response followed by scar tissue formation, hindering the repair of severed neural tracts and sensorimotor function.1 Injectable hydrogels consisting of a water-swollen polymer network can be engineered to mimic the environment of ... Read More

A well-designed isothermal laminar flow tubular reactor (LFTR) can be used as a source of high-quality kinetic rate data provided conditions are such that the plug flow idealization can be applied to its performance. In practice, meeting the necessary criteria for constant temperature ... Read More

Experts in the industry are seeing glass substrates as a promising alternative material for interposers, particularly for heterogeneous packaging such as 2.5D or 3D packages [1]. Recently, Intel revealed that they have developed one of the industry's first substrates specifically ... Read More

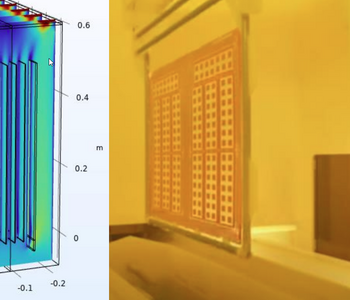

The Triton team was contracted to model and optimize a gas separation/pre-concentrator system involving selectively permeable membranes. The system would nominally include an input of mixed gas species at some driving pressure, a number of membrane modules, and separate permeate ... Read More

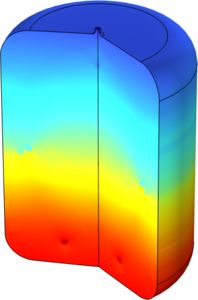

In our dynamic energy landscape, it is increasingly important to utilize energy efficiently and minimize waste. To achieve this, advancing our research beyond traditional battery storage, which has numerous limitations, is crucial. One promising solution is compressed gas energy storage. ... Read More

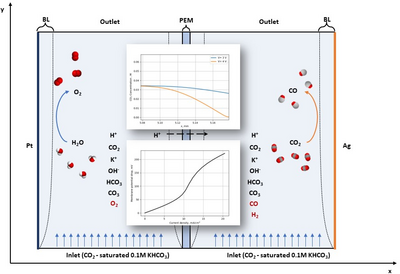

Artificial cascades for the electrochemical CO2 reduction reaction (CO2RR) to form value-added products are a developing technology, in which mass transport, reaction rates, local microenvironment and concentrations are all crucial parameters. These properties are highly dependent on the ... Read More

Toxic and hazardous air pollutants are released during chemical processes. The surrounding area of a chemical facility always has a high risk of air pollution by released chemicals. Furthermore, the personnel of the facility as well as community residents have risks of sudden ... Read More

INTRODUCTION: The “Schrödinger equation” is usually associated with quantum mechanics, however for the nonlinear version (NLSE), there are applications outside the realm of quantum mechanics. NLSE appears in branches of physics like a) the quantum physics Bose-Einstein condensation ... Read More

Climate change is a short-term problem which can no longer be ignored and affects everything, from global food security to geopolitics and economics: extreme weather phenomena, falling crops yields, decrease of water availability, sea level rise, extinction of several animal species, are ... Read More