See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

At the 2006 Winter Olympics, the jump length difference between first and second place was only 5cm. This illustrates why ski jumpers are constantly tinkering with their posture in order to gain even the smallest of advantages. Experiments such as those shown in Figures 1 and 2 (b), ... Read More

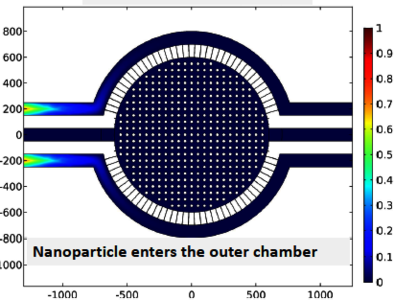

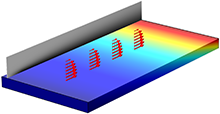

A simulation was performed to investigate the flow behaviors of drug delivery nanoparticles in a tumor-on-a-chip microfluidic device, which mimics a tumor cell having endothelial cells with micro-sized gaps. The Navier-Stokes equation and the convection-diffusion equation were used to ... Read More

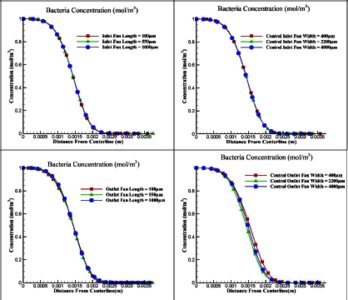

The ubiquitous nature of biofilms has led to a growing need to be able to detect, control, and maintain or remove them. Therefore a robust testing platform that allows for multiple analytical techniques is required to better understand their multitude of properties. The development of ... Read More

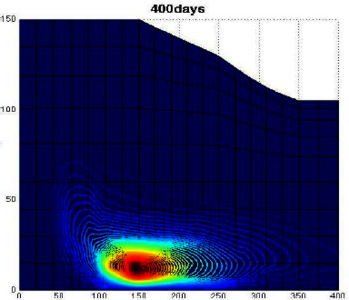

Hydraulic fracturing, or fracking, is a technique used to extract oil and gas in shale rock. A mixture of water, sand, and chemicals are pumped into the well at high pressures to keep the fissures open, which allows the gas to flow. Although intermediate casings are inserted into the ... Read More

Worldwide, the leading cause of mortality in children is acute respiratory infection, primarily associated with pneumonia. One of the essential tools used to treat life-threatening hypoxemia due to pneumonia is the appropriate use of supplemental oxygen. While oxygen therapy is ... Read More

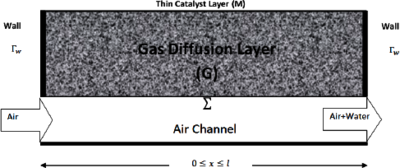

We develop a porosity-optimization problem to improve the electrochemical reactions taking place in hydrogen fuel cells. We introduce a mathematical model, which involves a system of conservation laws defined in a porous space domain. Our goal is to find the domain's optimal porosity ... Read More

Photo-bioreactors generate biomass by providing a controlled environment for the cultivation of algae due to photosynthesis. Algae cultivation can be controlled through the operating parameters and bioreactor environment to allow for high productivity and the use of systems with large ... Read More

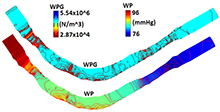

Three dimensional mathematical models are developed to simulate the blood flows in patient specific right coronary arteries with two stenoses. Simulations are carried out with various flow parameters under physiological conditions. Both Newtonian and non-Newtonian blood viscosity models ... Read More

Pore-level displacement of heavy-oil during thermal operations such as SAGD and CSS is a complex multi-scale phenomenon. As gravity drainage is the main depletion mechanism within the intergranular pore space, the surface tension-related phenomena are dominant in intra-granular micro ... Read More

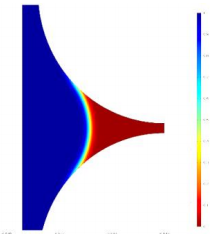

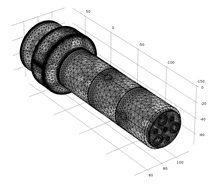

Present study discusses a new method of how to apply numerical simulation in COMSOL Multiphysics® software to improve the accuracy of polymer melts viscosity measurements. The main emphasis is placed on evaluating the effects of entrance and exit geometry of a capillary rheometer on ... Read More