See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Mobile robotics is an active research area, which is rapidly advancing thanks to a variety of technological developments in hardware and sensors. The operating environment and the tasks it must carry out are the main factors influencing the design of a climbing robot for industrial ... Read More

At department of Physics of the University of Orleans, a group of students in 'Licence de Physique' Bachelor level have experimented for the first time, the numerical project practice using the COMSOL Multiphysics® Class-Kit. This teaching unit, entitled Scientific Computation and ... Read More

Ultrasound technology is deployed in a variety of scientific and engineering applications, ranging from the non-invasive retrieval of system information to the stirring of molten metals. While ultrasonic sound waves found a wide range of applications in liquid media, the use of those in ... Read More

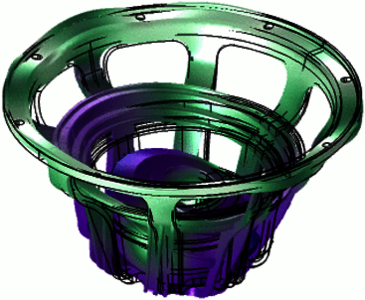

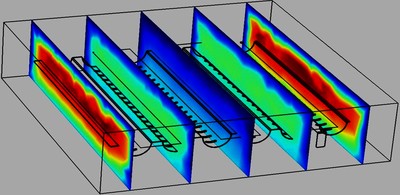

Finite Element simulations are becoming an increasingly powerful tool in the transducer design process. The development of user-friendly software and predefined interfaces able to provide physics setup to predict the loudspeaker complex behavior helps designers in the product development ... Read More

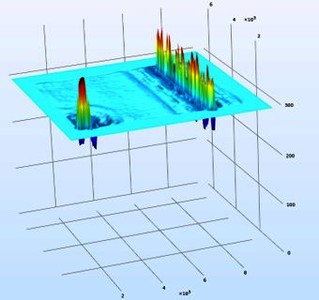

Irradiation of various surface materials by ultra-short laser radiation, typically with pulse widths of 10-300 fs, results in the development of Laser-induced self-organized periodic surface structures (ripples). The periodicity of these structures ranges from the wavelength <em>λ ... Read More

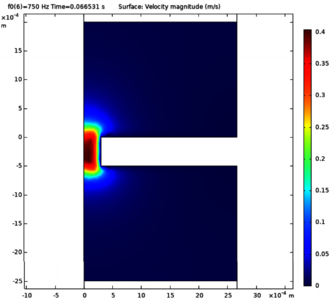

There is an increasing number of applications that requires using the time-dependent analysis of finite amplitude acoustic wave propagation or nonlinear acoustics. This study investigates an efficient finite element based numerical model of microperforated plate absorber using the time ... Read More

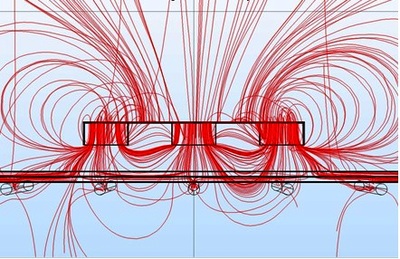

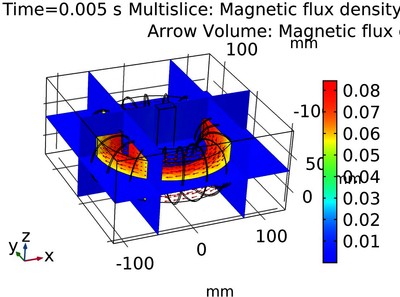

Current transformers (CTs) used for the purpose of measurement and design of our company has come a long way and have original designs. In the proposed paper, protection type current transformer design and manufacturing at medium voltage level (up to 36 kV) will be modeled. Protection ... Read More

This paper proposed design and implementation of a deodorizing electrostatic filter in hoods. The proposed model is aimed to be used in home applications. Electrostatic analysis is used to define maximum voltage level in order to refrain electrical breakdown (arc). It is vital because ... Read More

The fabrication of new reactor types has been simplified significantly by the rapid progression within the field of additive manufacturing. A reactor can be fit to nearly every specific task by varying its geometry and therefore its reactant hold-up and flow conditions in continuous ... Read More

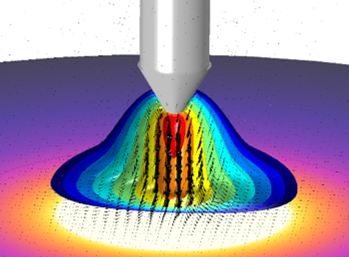

The heat and fluid flow calculation inside the melt pool in welding processes is a complex challenge. It can be useful to predict defects in the weld seam or to study the influence of some process parameters. Even if the required equations are mastered over the last few years, the cost ... Read More