See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

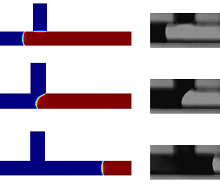

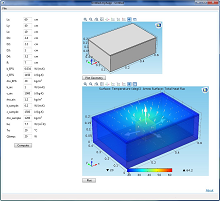

Describing and predicting the extent of the physicochemical processes as well as geometrical deformation taking place during food transformation is of major importance to control food functional properties. Unfortunately, only a few food-matrix models consider deformation particularly ... Read More

The future development of electric vehicles is now strictly linked with their batteries. In parallel of the actual research focused on the development of new materials and increase their performances in terms of energy, power, cost, durability and weight, it is necessary to develop ... Read More

The groundwater flow is accompanied by the electric field with potential called usually the streaming potential or the Self-Potential (SP) to be measured on the ground surface (e.g., Rizzo et al., 2004; Bolève et al., 2007; Jardani et al., 2009). We studied numerically the SP signals ... Read More

INTRODUCTION: Point-Of-Care (POC) and home care systems are of growing importance in biotechnological and medical applications [1]. These devices allow health monitoring directly at home or at the doctor’s office. Portability, low-cost, easy handling and compatibility with telemedicine ... Read More

Medical Cyclotrons are used in hospitals to manufacture radiopharmaceuticals. The nuclear reaction between the Cyclotron charged particles and a material takes place inside the so-called targets. In particular, gas target is used when a specific gas is bombarded with proton particles to ... Read More

The scientific method requires techniques for investigating phenomena, acquiring new knowledge, or correcting and integrating previous knowledge [1]. The Oxford English Dictionary defines the scientific method as "a method or procedure that has characterized natural science since the ... Read More

The unique optical properties of plasmon resonances in noble metal nanoparticles have been extensively investigated owing to their ability to enhance the electric field amplitude but also to tailor its spectral and spatial distribution. Among all application domains, nonlinear optics ... Read More

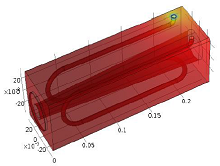

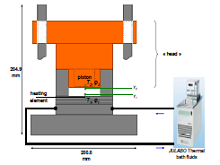

A new experimental device has been developed in order to characterize the phase change material (PCM) thermal properties (thermal conductivity k, sensible and latent heat thermal energy storage, cp and Lf) in the solid phase, during the solid-liquid transition and in the liquid phase. It ... Read More

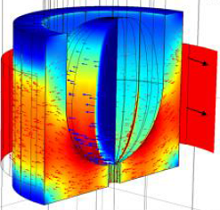

Examples of Electromagnetic processes are presented: (1) cold crucible, (2) electromagnetic pump, (3) DC electromagnetic brake. A combined approach by using multiphysics modeling with Comsol and experimental validation is used in order to give some guidelines for process improvement and ... Read More

Single turn coils are used in pulsed magnetic technologies for which both magneto-harmonic and transient magnetic analysis are required. We suggest studying one single turn coil example made of a conducting massive coil, an optional conducting field shaper and an internal conducting tube ... Read More