See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

SOI (Silicon on Insulator) technology utilizes silicon components on SiO2 layer. Propagating electric field distribution in a SOI waveguide is called mode of the waveguide. Photonic gratings are formed by etching grooves on the top of a waveguide. Gratings can operate in two directions. ... Read More

Fixed nitrogen is used in many forms ranging from nitric acid to hydrogen cyanide and is used as such for industrial applications. The reactions to produce these products are highly endothermic and favored by high-temperature processing. The most basic route of chemically fixing nitrogen ... Read More

Aim of the study is to determine the influence of some of the most important operating variables, especially humidity and temperature, of drying air on the performance of cooking process of pork meat. The process is simulated using finite elements software COMSOL Multiphysics®. The ... Read More

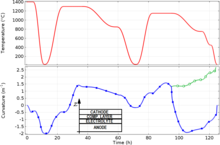

Lithium microbatteries are replacing conventional power sources in many microsystems areas such as wireless sensors and biomedical monitors. In many of these applications, compact models of micro batteries are needed both at the microsystems design stage and at the real-time power ... Read More

This work falls into the framework of an ESA experiment, which consists of observing the behavior of patterns and structures that can be formed after instability onset in a HFE7100 liquid layer, evaporating into a nitrogen gas flow. This study is performed by a three-dimensional ... Read More

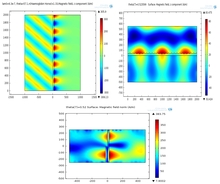

Surface plasmon resonance (SPR) sensors proved themselves as a promising device for many kinds of applications such as optical biosensing, binding constant determinationor nanofilm thickness measurements. Here we simulate using COMSOL Multiphysics® the light-polaritons coupling for the ... Read More

In fractured reservoirs, much of the oil is stored in low permeable matrix blocks that are surrounded by a high permeability fracture network. Therefore, production from fractured reservoir depends on the transfer between fracture and matrix, which is critically dependent on their ... Read More

A solid oxide fuel cell (SOFC) is composed of four layers (anode, electrolyte compatibility layer and cathode) of different ceramic materials. The anode layer is produced by tape casting, the remaining layers are deposited by screen-printing. The layers are sintered together at high ... Read More

During examination of molecular gas flow in freeze dryers in near-vacuum properties, an idea came up to model a molecular fish trap nozzle. An appropriate shape of this fish trap nozzle allows to separate free flowing molecules into 2 chambers, and obtain a pressure gain in a isothermal ... Read More

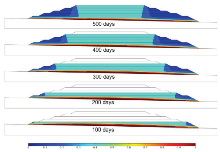

Heap leaching in the mining industry had become a sophisticated practice at least 500 years ago. It is a mineral processing technology whereby piles of crushed Run-of–Mine rock are leached with chemical solutions to extract minerals. The goal of this work is to contribute to the ... Read More