See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

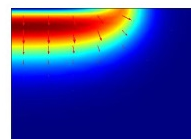

Within this study a model of a single discharge of micro scale EDM was developed in accordance with Schulze et al [1]. The specific computation of the growth of the plasma channel has been derived from this literature. Applying COMSOL Multiphysics® a pseudo 3-D geometry was created based ... Read More

Electrochemical Machining is a potential procedure for micro manufacturing technology. Especially the absence of machining forces makes it advantageous for processing metals with high hardness and for the generation of complicated geometries. Applying a closed electrolytic free jet (Jet ... Read More

Gallium nitride (GaN) and its related nitride alloys with special physical properties are in technical areas of high interest. The growing of gallium nitride boules on non-native sapphire or silicon carbide requires complicated mechanisms of defect reduction in the lattice structure. ... Read More

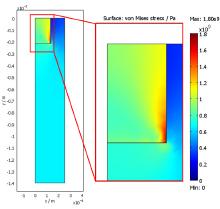

The fabrication of piezo aluminium composite modules for sensor and actor applications with mass production technologies is in the scope of the SFB/Transregio 39 PT-PIESA project funded by the (German Research Foundation). After forming of cavities with a width of 0.3 mm into aluminium ... Read More

Porous membranes with pore sizes in the micrometer scale are required in many micro systems dedicated to biological and chemical applications. If their thickness is in the same dimension like the pore diameter they are called microsieves. On the one hand, a thin membrane guarantees a ... Read More

Micro impact extrusion is investigated at Chemnitz University of Technology as a potential procedure for large area machining of micro cavities within the scope of the SFB/Transregio 39 PT-PIESA of the German Research Foundation. Applying impact extrusion micro forming is done by ... Read More