See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

In this poster we present the results of the strategy for calibrating the COMSOL Multiphysics® model to simulate the laser bonding process (LADB) of Mems chips. A specific aspect of this work is to calibrate the COMSOL Multiphysics® heat model loss by measuring with a miniature ... Read More

Laser Powered Homogenous Pyrolysis (LPHP), a non-isothermal wall-less plug flow reactor using cw-IR CO2 laser heating by fast vibrational–translational (V–T) energy transfer, is a common technique for high temperature pyrolysis in the gas phase with minimal catalytic effect of hot ... Read More

This work presents the design and modelling of a quantum sensor based on the NV (Nitrogen-Vacancy) defect in the diamond lattice for in vitro biomedical applications. The platform employs ~150nm HPHT (High Pressure High Temperature) diamond nanoparticles (NDs) containing NV centers, ... Read More

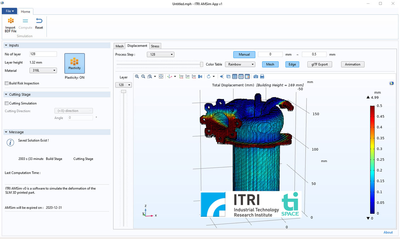

The laser powder bed fusion (LPBF) process involves a highly localized laser heating, resulting in a large thermal gradient that induces residual thermal stress and deformation in the finished build. The excessive residual deformation in the direction normal to in the process plane could ... Read More

Wearable devices are drastically transforming the healthcare industry by enabling continuous, real-time monitoring of physiological and biochemical properties outside clinical settings. One particularly important application is the monitoring of stress; a significant factor linked to ... Read More

Additive manufacturing is attracting more and more interest. Laser Cladding is one of these additive manufacturing processes. As it is a blown powder process, here a melt pool formation & fusion by moving the laser beam, into which powder is blown and molten & surface tension gradient ... Read More

Abstract. A Laser Focusing system (LFS) focuses a single laser beam (single Channel) or multiple laser beams (multi - channel) onto a surface (Specimen). The general motive of a LFS is to focus a train of brief pulses or a continuous beam of light onto a Specimen which heats up its ... Read More

In the field of laser applications, surface treatment is highly studied. Two process categories are commonly used. First processes use very short pulses (femto or pico seconds) known to avoid thermal effects and to have high spatial resolutions. Second processes have higher interaction ... Read More

Here we present a simulation for evaluation of novel obscurant candidates under high-energy laser (HEL) illumination. This approach incorporates thermal modeling into obscurant characterization, allowing for evaluation of the temperature increase of the candidate obscurants as well as ... Read More

A critical constraint in handling high power laser beams approaching 100kW of peak average power is thermal management due to laser absorption. Seurat Technologies uses a unique, optically addressed spatial light modulator (OASLM) with liquid crystals to dynamically shape laser beams for ... Read More