See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Photoacoustic spectroscopy (PAS) enables highly sensitive gas detection without optical detectors by directly measuring the sound generated from light absorption. However, the performance of PAS systems strongly depends on the photoacoustic cell’s acoustic design. In this work, we ... Read More

Microfluidic systems traditionally rely on fixed physical barriers to manipulate fluids and particles. While effective, these static structures lack the flexibility required for dynamic or multifunctional applications. In this work, recently published in Nature Photonics [1], we present ... Read More

Laser technologies such as welding, cutting and metal deposition are widely used in the industry. High quality requirements regarding process products cause that there is often a need to monitor the process. For this purpose, optical sensors integrated with a laser head are often used. ... Read More

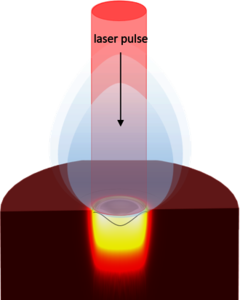

A lateral observation of laser-induced keyhole through the quartz window is an easy and cheap experimental method. It opens an interesting perspective for the study of keyhole asymmetry in case of dissimilar metal combinations. To quantify the effect of quartz window on the observed ... Read More

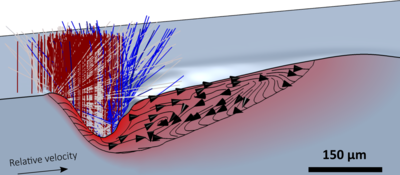

Whereas the physic models of fluid lubrication should be able to provide quantitative predictions to industrial problems, it is somehow demanding to provide the input data to feed these high-level equation systems. The operating conditions are generally available, and the material ... Read More

The present work introduces a new methodology, based on COMSOL Multiphysics® Application Builder, to account for the “beam trapping” effect in multiphysical modelling of laser welding. Incident intensities involved in laser welding processes are high enough to induce material ... Read More

Laser surface texturing has emerged as a promising texturing technique due to properties such as excellent repeatability, non-contact process, the ability to achieve small-size features and high-quality finishing. The work described here is part of the H2020 research program called SHARK ... Read More

New emerging trends in the MEMS market are linked to the availability of small, reliable and miniature sensors for harsh environment applications to increase penetration in all application fields, considering very wide operating condition ranges. These trends are pushed forward by the ... Read More

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. In this paper, the focus is on ... Read More

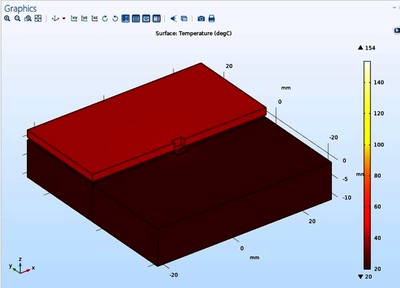

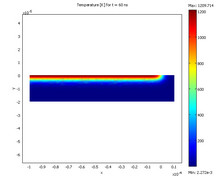

A 2D transient heat conduction model was created in COMSOL Multiphysics to simulate temperature changes in material irradiated by a KrF laser beam confined on silicon’s surface. In this paper, the obtained results are shown and discussed in case of bulk Silicon. The heat source is ... Read More