See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

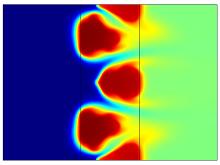

Emulsions, small liquid droplets of oil in water or water in oil, find wide application in, pharmaceutical products, fine chemicals, analytical chemistry. Microfluidic devices allow creation of uniform droplets with a tight distribution. The COMSOL Multiphysics® software model presented ... Read More

Introduction The topology optimization method is becoming increasingly popular as a design tool for multiphysics systems [1,2]. Topology optimization of fluid-thermal systems has been presented for example in [3] for forced convective heat transfer and in [4] for natural convection ... Read More

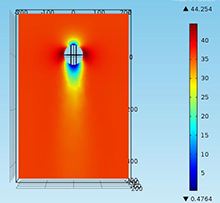

This paper is an investigation into the effect of blood vessel movement on measurement accuracy of blood flow rate using magnetic flow meters. The investigation used a Finite Element model of the magnetic flowmeter built using COMSOL Multiphysics® software by integrating the modules of ... Read More

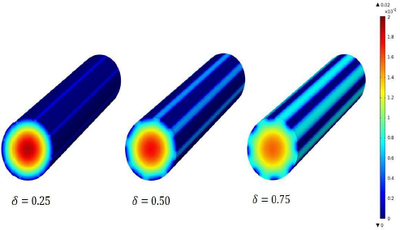

The present work investigates the role of suspended liquid-gas interfaces for applications involving the reduction in flow resistance using the COMSOL multiphysics software. A pressure-driven viscous flow of a liquid through microtubes containing superhydrophobic surfaces patterned with ... Read More

Additive manufacturing gathers technologies where near net shape components are produced by depositing successive layers of materials. Among these technologies, the Layer Beam Melting (LBM) process – often referred to as Selective Laser Melting (SLM) – is garnering industrial interest, ... Read More

Analysis of burning candles is extremely complex; combustion produces a highly non-linear temperature profile through the flame in which local temperatures may exceed 1400 °C. Heat transfer includes radiation, conduction and convection components and the low melting point of the candle ... Read More

Conventional swing is one phenomenon which a bowler uses to gain an advantage over the batsman. This study involved simulating conventional swing in the CFD Module of COMSOL Multiphysics® software and comparing the simulated results with experimental results of previous researchers. The ... Read More

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... Read More

While electrostatic actuators feature prominently among the most widely employed classes of actuators for microelectromechanical systems (MEMS), conventional embodiments of these devices (e.g., parallel plate structures) notoriously suffer from several significant drawbacks. Most ... Read More

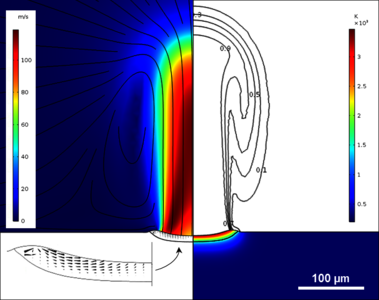

Laser drilling of titanium and its alloys is widely used in aerospace industry, as it offers selective removal of material at high accuracy and speed. However, laser drilling often inherits defects such as large heat affected zone, micro cracks and recast layer. These defects depend upon ... Read More