See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

The motion of a fluid can be described by the incompressible Navier-Stokes equations (NSE). A single particle embedded in the fluid experience a resistance resulting from a friction force. The friction force depends typically on the velocity but is directed in the opposite direction to ... Read More

The appearance of high concentrations of the radioactive noble gas Radon (Rn) in soil requires the installation of protection and mitigation mechanisms to hinder the Rn diffusion into buildings. In the present study, two schemes for the Rn diffusion reduction were explored with numerical ... Read More

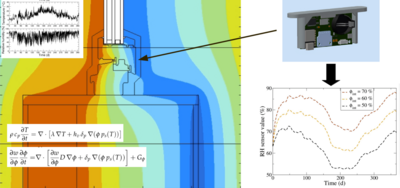

The material wood is frequently used in construction industry for several elements such as window frames. However, as a hygrothermal material, wood is sensitive to moisture induced damage. In this context, the moisture uptake of wood based windows logged with an integrated relative ... Read More

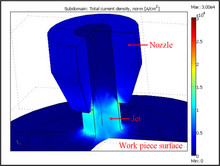

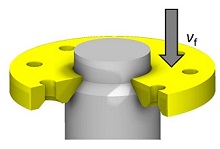

Electrochemical Machining with a closed electrolytic free jet is a special procedure to generate complex micro structures by help of anodic dissolution. The work piece shape is fabricated by supplying an electrolytic current through an electrolyte jet ejected from a small nozzle. In ... Read More

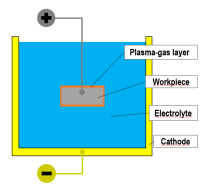

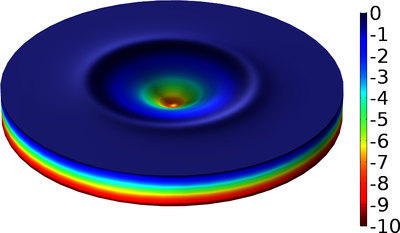

Plasma electrolytic polishing (PeP) is an electrochemical method for surface treatment. In detail PeP is a special case of anodic dissolution [1] that unlike electrochemical polishing requires higher voltage and uses environment friendly aqueous solutions of salts. When the process ... Read More

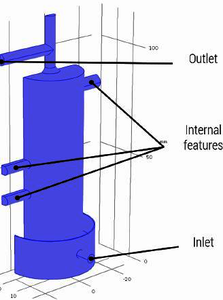

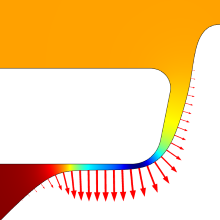

Manufacturing and finishing of components with complex internal features is a significant challenge. Industrial sectors like automotive industry, aeronautics or medical technology require these internal features with highest precision and repeatability. Such components are often machined ... Read More

Actual trends in lightweight construction and safety-relevant technologies cause an increasing demand for reliable design of joining connections. Increasing power density and compact design require dimensioning of joints with low safety factors. Thereby additional security measures are ... Read More

The machining of hardened steel or powder metallurgical steel, for example to manufacture impact extrusion punches, is a big challenge for conventional machining technology as milling or turning. A non-conventional machining technology is Electrochemical Machining (ECM), which allows ... Read More

Two-component adhesives are commonly used for sealing and joining in transport applications for mechanically highly stressed connections. At the Chemnitz University of Technology an innovative system technology for the user-friendly, wireless and energy-efficient processing of two ... Read More

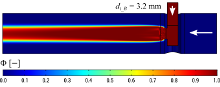

Electrochemical Machining (ECM) is a non-conventional machining technology which allows for surface structuring and shaping of metallic workpieces with high accuracy and surface quality. The machining principle of ECM is electrolysis. Hence, the mechanical properties of the workpiece ... Read More