COMSOL Events Calendar

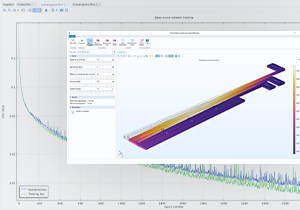

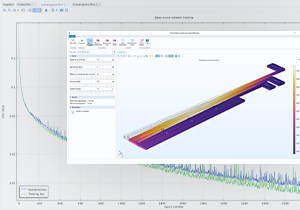

Modeling Workflow

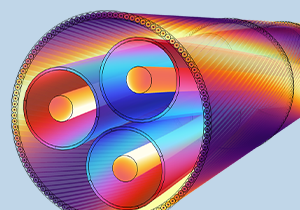

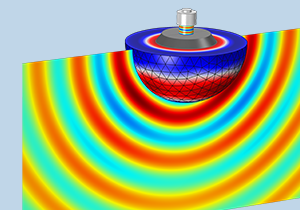

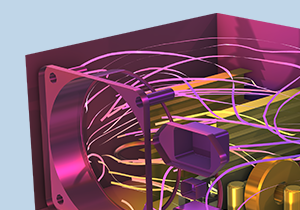

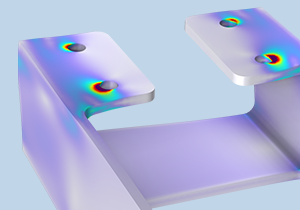

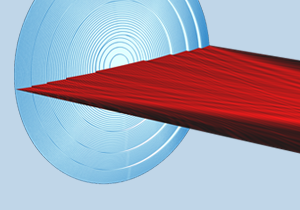

Electromagnetics

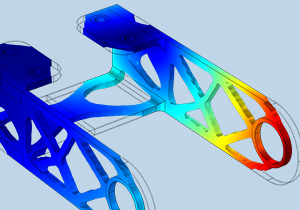

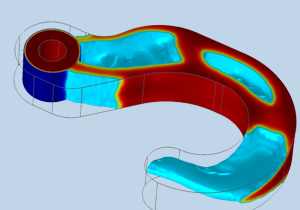

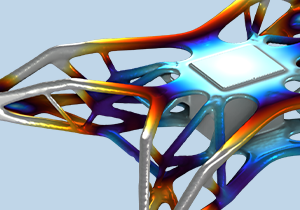

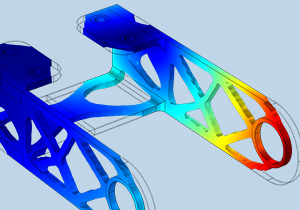

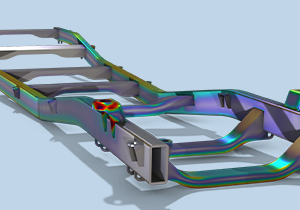

Structural & Acoustics

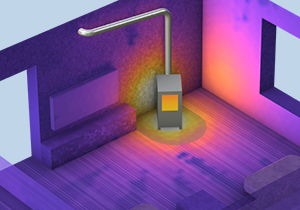

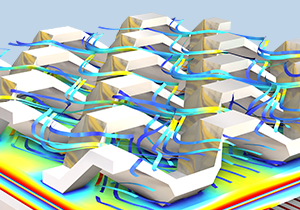

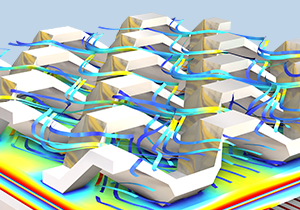

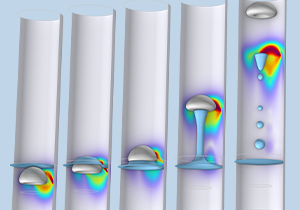

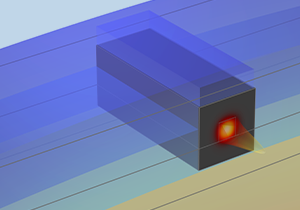

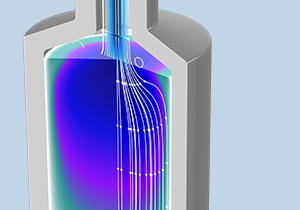

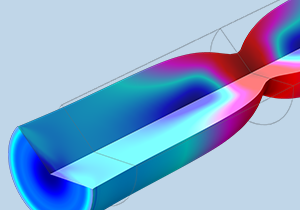

Fluid & Heat

Chemical

Interfacing

General

Show as:

Time zone:

My Time (EST)

Host Time

08:00 AM - 08:00 PM

Showing events starting between: 8 a.m. – 8 p.m.

Search

Upcoming Events

Loading Events

Feb 24

| 2:00 p.m. EST

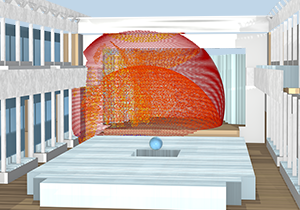

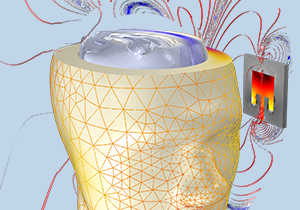

Uncertainty Quantification for Acoustics

COMSOL

Webinar

Online

Feb 25

| 2:00 p.m. EST

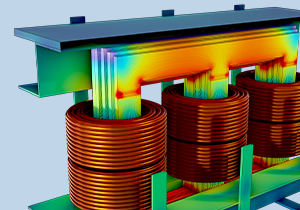

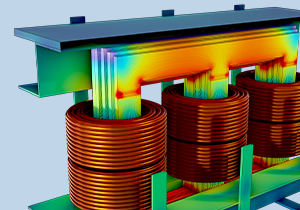

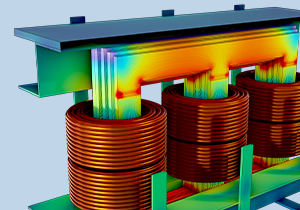

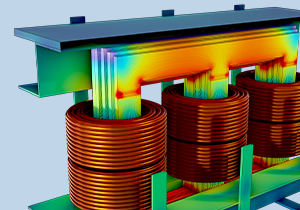

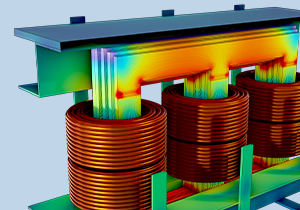

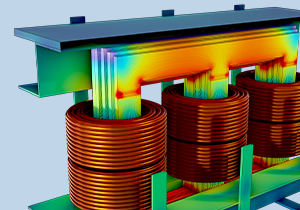

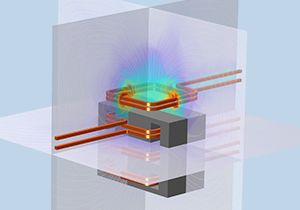

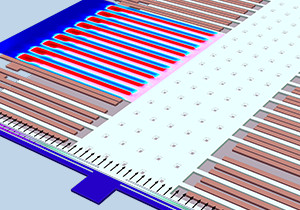

Multiphysics Modeling of Power Electronics

Physics Today

Webinar

Online

Feb 26

| 9:00 a.m. GMT

The Basics of COMSOL® in 18 Minutes

COMSOL

Webinar

Online

Feb 26

| 11:00 a.m. EST

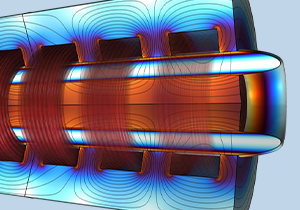

Modeling Rotordynamics with COMSOL Multiphysics®

COMSOL

Webinar

Online

Mar 3

| 8:00 a.m. CET

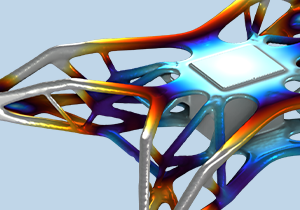

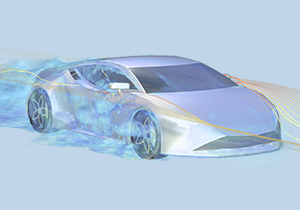

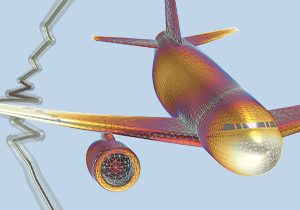

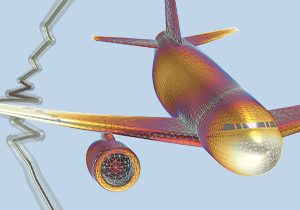

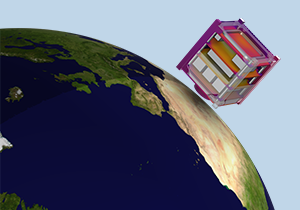

Modeling for Aerospace Engineering with COMSOL Multiphysics®

COMSOL

Webinar

Online

Mar 3–6

| 11:00 a.m. EST

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Mar 3

| 2:00 p.m. EST

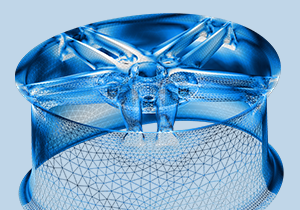

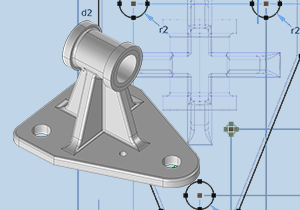

Editing, Repairing, and Combining Imported STL Files with CAD

COMSOL

Webinar

Online

Mar 10

| 9:00 a.m. CET

GPU Acceleration in COMSOL®

COMSOL

Webinar

Online

Mar 10

| 10:00 a.m. GMT

Time-Optimal Control with COMSOL Multiphysics® in 18 Minutes

COMSOL

Webinar

Online

Mar 10–13

| 11:00 a.m. EDT

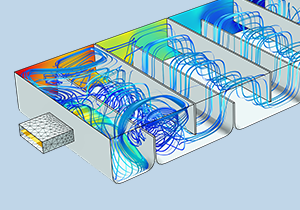

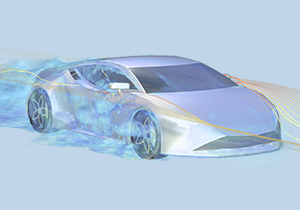

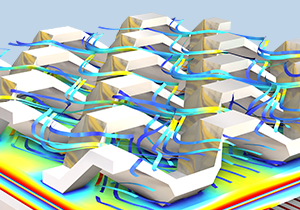

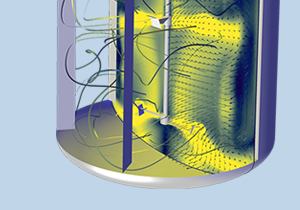

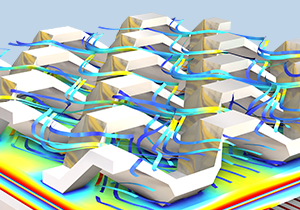

CFD Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Mar 12

| 2:00 p.m. EDT

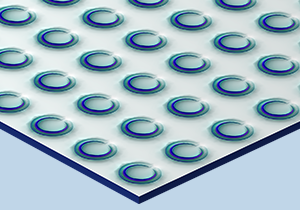

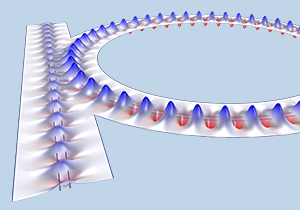

Phased-Array Antenna Modeling: Techniques to Optimize RF Design

Machine/Electronic Design

Webinar

Online

Mar 15–19

| 10:00 a.m. CDT

AMPP

COMSOL

Exhibition

Houston

Mar 17

| 9:00 a.m. CET

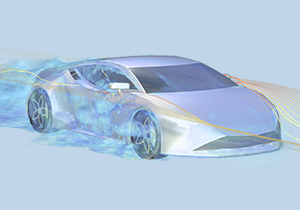

CFD Modeling with COMSOL Multiphysics® in 18 Minutes

COMSOL

Webinar

Online

Mar 17

| 11:00 a.m. EDT

Modeling Gyroscopes and Accelerometers in COMSOL Multiphysics®

COMSOL

Webinar

Online

Mar 24

| 9:30 a.m. CET

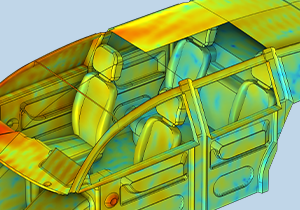

Analisi acustiche nel settore automobilistico con COMSOL Multiphysics®

COMSOL

Webinar

Online

Mar 24–27

| 11:00 a.m. EDT

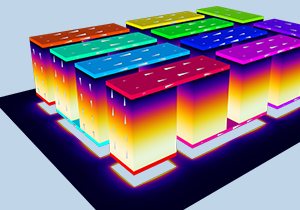

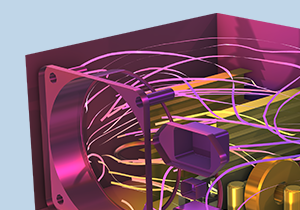

AC/DC Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Mar 25

| 10:00 a.m. GMT

Solving Large Models in COMSOL Multiphysics®

COMSOL

Webinar

Online

Mar 26

| 11:00 a.m. EDT

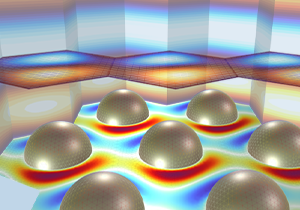

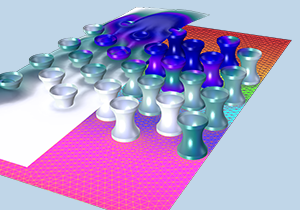

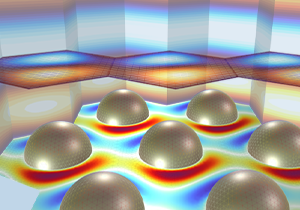

Photo-Thermo-Optical Effects in Metasurfaces: From Optical to Thermochemical Devices

Photonics Spectra

Webinar

Online

Mar 26

| 11:00 a.m. EDT

COMSOL Day: Electric Power

COMSOL

COMSOL Day

Online

Apr 14

| 8:00 a.m. CEST

Modeling Granular Flow in COMSOL®

COMSOL

Webinar

Online

Apr 14–17

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Apr 21

| 8:00 a.m. CEST

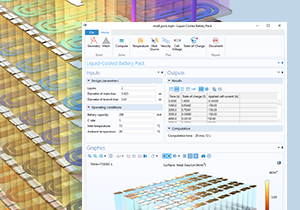

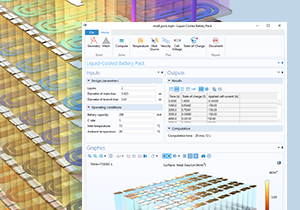

Simulation Apps & Digital Twins for the Renewable Energy Industry

COMSOL

Webinar

Online

Apr 21–24

| 11:00 a.m. EDT

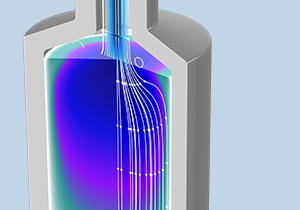

Heat Transfer Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Apr 23

| 8:30 a.m. CEST

Modellazione multifisica dei dispositivi di comunicazione ad alta velocità

COMSOL

Webinar

Online

Apr 28–29

| 9:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Burlington

May 5–8

| 11:00 a.m. EDT

Acoustics Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

May 8

| 12:00 p.m. PDT

COMSOL Simulation Summit: Santa Clara

COMSOL

Summit

Santa Clara

May 12

| 8:00 a.m. CEST

Equation-Based Modeling with COMSOL®

COMSOL

Webinar

Online

May 19

| 8:00 a.m. CEST

Preparing CAD for Analysis with COMSOL®

COMSOL

Webinar

Online

May 19–22

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Jun 9

| 8:00 a.m. CEST

Modeling Electric Motors & Generators

COMSOL

Webinar

Online

Jun 23

| 8:00 a.m. CEST

CFD Modeling with COMSOL in 18 Minutes®

COMSOL

Webinar

Online

Jun 23–26

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Showing 8 of 33 events

Showing 33 of 33 events

| Date | Time | Title | Type | Host | Discipline |

|---|---|---|---|---|---|

| Feb 24 | 2:00 p.m. |

Uncertainty Quantification for Acoustics |

Webinar | COMSOL-Online |

|

| Feb 25 | 2:00 p.m. |

Multiphysics Modeling of Power Electronics |

Webinar | Physics Today - Online |

|

| Feb 26 | 9:00 a.m. |

The Basics of COMSOL® in 18 Minutes |

Webinar | COMSOL-Online |

|

| Feb 26 | 11:00 a.m. |

Modeling Rotordynamics with COMSOL Multiphysics® |

Webinar | COMSOL-Online |

|

| Mar 3 | 8:00 a.m. |

Modeling for Aerospace Engineering with COMSOL Multiphysics® |

Webinar | COMSOL-Online |

|

| Mar 3–6 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Mar 3 | 2:00 p.m. |

Editing, Repairing, and Combining Imported STL Files with CAD |

Webinar | COMSOL-Online |

|

| Mar 10 | 9:00 a.m. |

GPU Acceleration in COMSOL® |

Webinar | COMSOL-Online |

|

| Mar 10 | 10:00 a.m. |

Time-Optimal Control with COMSOL Multiphysics® in 18 Minutes |

Webinar | COMSOL-Online |

|

| Mar 10–13 | 11:00 a.m. |

CFD Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Mar 12 | 2:00 p.m. |

Phased-Array Antenna Modeling: Techniques to Optimize RF Design |

Webinar | Machine/Electronic Design - Online |

|

| Mar 15–19 | 10:00 a.m. |

AMPP |

Special Event | COMSOL-Houston |

|

| Mar 17 | 9:00 a.m. |

CFD Modeling with COMSOL Multiphysics® in 18 Minutes |

Webinar | COMSOL-Online |

|

| Mar 17 | 11:00 a.m. |

Modeling Gyroscopes and Accelerometers in COMSOL Multiphysics® |

Webinar | COMSOL-Online |

|

| Mar 24 | 9:30 a.m. |

Analisi acustiche nel settore automobilistico con COMSOL Multiphysics® |

Webinar | COMSOL-Online |

|

| Mar 24–27 | 11:00 a.m. |

AC/DC Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Mar 25 | 10:00 a.m. |

Solving Large Models in COMSOL Multiphysics® |

Webinar | COMSOL-Online |

|

| Mar 26 | 11:00 a.m. |

Photo-Thermo-Optical Effects in Metasurfaces: From Optical to Thermochemical Devices |

Webinar | Photonics Spectra - Online |

|

| Mar 26 | 11:00 a.m. |

COMSOL Day: Electric Power |

COMSOL Day | COMSOL-Online |

|

| Apr 14 | 8:00 a.m. |

Modeling Granular Flow in COMSOL® |

Webinar | COMSOL-Online |

|

| Apr 14–17 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Apr 21 | 8:00 a.m. |

Simulation Apps & Digital Twins for the Renewable Energy Industry |

Webinar | COMSOL-Online |

|

| Apr 21–24 | 11:00 a.m. |

Heat Transfer Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Apr 23 | 8:30 a.m. |

Modellazione multifisica dei dispositivi di comunicazione ad alta velocità |

Webinar | COMSOL-Online |

|

| Apr 28–29 | 9:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Burlington |

|

| May 5–8 | 11:00 a.m. |

Acoustics Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| May 8 | 12:00 p.m. |

COMSOL Simulation Summit: Santa Clara |

Special Event | COMSOL-Santa Clara |

|

| May 12 | 8:00 a.m. |

Equation-Based Modeling with COMSOL® |

Webinar | COMSOL-Online |

|

| May 19 | 8:00 a.m. |

Preparing CAD for Analysis with COMSOL® |

Webinar | COMSOL-Online |

|

| May 19–22 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Jun 9 | 8:00 a.m. |

Modeling Electric Motors & Generators |

Webinar | COMSOL-Online |

|

| Jun 23 | 8:00 a.m. |

CFD Modeling with COMSOL in 18 Minutes® |

Webinar | COMSOL-Online |

|

| Jun 23–26 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

Trainings by Certified Consultants

On-Demand Webinars

Modélisation géométrique avec COMSOL Multiphysics®

Webinar

Feb 19

Analisi e visualizzazione dei risultati in COMSOL Multiphysics®

Webinar

Feb 18

Modeling Nonlinear Photonics in Dielectric Resonant Metasurfaces Using COMSOL®

Webinar

Feb 18

Modéliser la Corrosion et les Systèmes de Protection contre la Corrosion avec COMSOL Multiphysics®

Webinar

Feb 12

非线性结构材料参数估计

Webinar

Feb 05

Modeling and Simulation of MEMS Devices

Webinar

Feb 04

Modeling Photonic Crystals in COMSOL Multiphysics

Webinar

Jan 29

Modéliser les batteries avec COMSOL Multiphysics®

Webinar

Jan 29

COMSOL® 多物理场仿真在功率半导体中的应用

Webinar

Jan 29

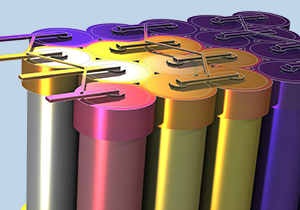

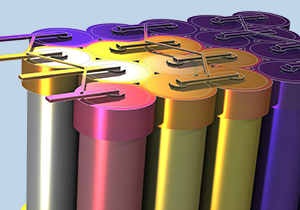

Modeling Emerging Battery Technologies with COMSOL Multiphysics®

Webinar

Jan 28

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Jan 27

Shape and Topology Optimization with COMSOL Multiphysics®

Webinar

Jan 22

Modéliser les Bobines avec COMSOL Multiphysics®

Webinar

Jan 22

Automotive Acoustics Analysis Using COMSOL Multiphysics

Webinar

Jan 21

Modellare i flussi turbolenti con COMSOL Multiphysics®

Webinar

Jan 20

COMSOL® 中的流热耦合仿真

Webinar

Jan 15

Polymer Flow Modeling

Webinar

Jan 13

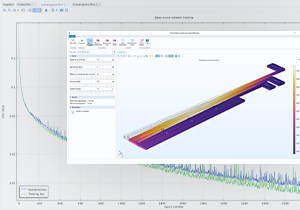

在 COMSOL® 中实现仿真流程自动化

Webinar

Jan 08

多物理场仿真结果的处理与可视化

Webinar

Dec 25

COMSOL Multiphysics® 6.4 版本功能简介

Webinar

Dec 18

Parameter Estimation for Nonlinear Materials

Webinar

Dec 11

Modéliser le contact mécanique avec COMSOL Multiphysics®

Webinar

Dec 11

COMSOL® 中的等离子体仿真

Webinar

Dec 11

Introducing COMSOL Multiphysics® Version 6.4

Webinar

Dec 10

Migliorare la progettazione e la gestione termica delle batterie

Webinar

Dec 10

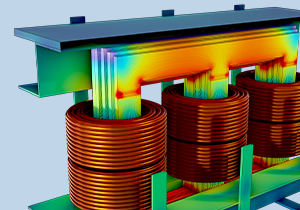

Multiphysics Simulation of Power Transformers

Webinar

Dec 09

Modéliser les dispositifs médicaux et biomédicaux avec COMSOL Multiphysics®

Webinar

Dec 04

COMSOL® 中的化学反应工程仿真

Webinar

Dec 04

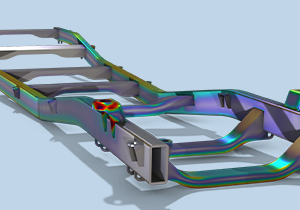

Multiphysics Simulation for Vehicle Electrification

Webinar

Dec 02

COMSOL® 多物理场仿真在新能源汽车领域中的应用

Webinar

Nov 27

Optimising Manufacturing Processes Through Simulation

Webinar

Nov 26

Simulare per il biomedicale con COMSOL Multiphysics®

Webinar

Nov 26

Designing Efficient Electric Motors with COMSOL Multiphysics

Webinar

Nov 26

使用 COMSOL® 模拟声学超材料

Webinar

Nov 20

Efficient Battery Modeling with Surrogate Models

Webinar

Nov 19

Automating Your Modeling Workflow in COMSOL Multiphysics®

Webinar

Nov 18

Modéliser le packaging et les tests de dispositifs électroniques avec COMSOL Multiphysics®

Webinar

Nov 13

使用 COMSOL 模拟 RF 和光学周期性结构

Webinar

Nov 13

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Nov 11

Modeling Pipe Flow & Heat in COMSOL Multiphysics®

Webinar

Nov 06

Progettare per l’industria aerospaziale con COMSOL Multiphysics®

Webinar

Nov 05

Modeling Gyroscopes and Accelerometers in COMSOL Multiphysics®

Webinar

Oct 30

COMSOL 多物理场仿真在功率器件中的应用

Webinar

Oct 23

Personalizza le tue equazioni con COMSOL Multiphysics®

Webinar

Oct 22

Modéliser les écoulements turbulents avec COMSOL Multiphysics®

Webinar

Oct 16

COMSOL 多物理场仿真在数字岩心中的应用

Webinar

Oct 16

Modeling and Simulation for Electric Motor Design

Webinar

Oct 15

Simulating Electrical Power Systems for the Grid

Webinar

Oct 14

Unravelling Chemomechanical Effects in Lithium-Ion Batteries

Webinar

Oct 09

Optimierung keramischer 3D-Drucke durch Simulation

Webinar

Oct 09

Simulare sistemi elettrici di potenza

Webinar

Oct 08

Modeling Next-Generation Battery Technologies with COMSOL Multiphysics®

Webinar

Oct 06

Modeling Emerging Battery Technologies with COMSOL Multiphysics®

Webinar

Sep 25

Modéliser le rayonnement thermique avec COMSOL Multiphysics®

Webinar

Sep 25

在 COMSOL 中创建、训练和使用代理模型

Webinar

Sep 25

Ottimizzare le simulazioni di meccanica strutturale

Webinar

Sep 24

Modeling and Simulation of MEMS Devices

Webinar

Sep 23

Elektrische Entladungen modellieren

Webinar

Sep 18

Modéliser les moteurs électriques et les générateurs avec COMSOL Multiphysics®

Webinar

Sep 18

电力设备噪声的多物理场仿真

Webinar

Sep 18

Costruire app di simulazione e digital twin con COMSOL Multiphysics®

Webinar

Sep 16

Modeling Reaction Kinetics and Pharmacokinetics with COMSOL Multiphysics®

Webinar

Sep 11

Modeling Ultrasound for Biomedical Applications

Webinar

Sep 09

Optimization of Thermal Management Systems

Webinar

Sep 03

Prediction of Electromagnetic Signatures of Naval Vessels with COMSOL Multiphysics

Webinar

Aug 28

Modellare sistemi ottici con COMSOL Multiphysics®

Webinar

Aug 28

Bonnes pratiques pour évaluer et afficher les résultats dans COMSOL Multiphysics®

Webinar

Aug 28

COMSOL 多物理场仿真在声学中的应用

Webinar

Aug 27

COMSOL 仿真 App 开发、部署和应用

Webinar

Aug 21

Modeling Room Acoustics in COMSOL Multiphysics®

Webinar

Aug 19

Modeling and Simulation for Electric Motor Design

Webinar

Aug 14

使用 COMSOL 模拟热应力

Webinar

Aug 14

Moisture Transport Modeling in COMSOL Multiphysics®

Webinar

Aug 07

COMSOL 在半导体封测中的应用

Webinar

Aug 07

Modeling Hydrogen Fuel Cells and Electrolyzers

Webinar

Aug 06

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Aug 05

Modeling Acoustic Metamaterials in COMSOL Multiphysics

Webinar

Jul 31

使用 COMSOL 模拟多孔介质流和地下水流

Webinar

Jul 31

Fatigue and Durability Analysis Using COMSOL Multiphysics®

Webinar

Jul 24

Comment créer des modèles de substitution avec COMSOL Multiphysics®

Webinar

Jul 24

多物理场仿真在电力变压器中的应用

Webinar

Jul 24

Biomedical Modeling with COMSOL Multiphysics

Webinar

Jul 17

COMSOL 多物理场仿真在光学领域中的应用

Webinar

Jul 16

Understanding Liquid Metal Transport in Magnetic Fields — Simulating Magnetohydrodynamic Duct Flow

Webinar

Jul 11

Modeling Electric Motors and Drivetrains

Webinar

Jul 10

Créer des applications de simulation et des jumeaux numériques avec COMSOL Multiphysics®

Webinar

Jul 10

多物理场仿真在半导体制程中的应用

Webinar

Jul 10

COMSOL® 中的低频电磁场仿真

Webinar

Jul 03

Memristor Modeling with COMSOL Multiphysics®

Webinar

Jul 02

Modeling Fluid Mixers and Stirred Tank Reactors in COMSOL Multiphysics®

Webinar

Jun 26

使用 COMSOL 进行流固耦合仿真

Webinar

Jun 26

COMSOL® 中的传热仿真

Webinar

Jun 19

Modellierung optischer Nanostrukturen mit COMSOL Multiphysics®

Webinar

Jun 17

Underwater Acoustics

Webinar

Jun 12

Optimization in Structural Mechanics

Webinar

Jun 12

Hydrogen Technology Innovation with Simulation

Webinar

Jun 12

Modeling Hydrogen Fuel Cells and Electrolyzers

Webinar

Jun 12

Améliorer la gestion thermique des dispositifs électroniques avec COMSOL Multiphysics®

Webinar

Jun 12

多物理场仿真在先进封装中的应用

Webinar

Jun 12

Modeling Chemical Reactions and Reacting Flows Using COMSOL Multiphysics®

Webinar

Jun 05

COMSOL® 在电力设备中的应用

Webinar

Jun 05

Migliorare le tecnologie per la decarbonizzazione con la simulazione

Webinar

Jun 04

COMSOL® 网格划分功能介绍

Webinar

May 29

Introduction to Multibody Dynamics Modeling with COMSOL Multiphysics

Webinar

May 28

Automotive Acoustics Analysis Using COMSOL Multiphysics®

Webinar

May 27

Comment faire de l’optimisation et de l’estimation de paramètres avec COMSOL Multiphysics®

Webinar

May 22

COMSOL® 在半导体薄膜沉积工艺中的应用

Webinar

May 20

COMSOL® 中的结构力学仿真

Webinar

May 15

Analizzare i fenomeni acustici con la simulazione

Webinar

May 14

Modélisation multiphysique pour l’aéronautique et le spatial avec COMSOL Multiphysics®

Webinar

May 13

Improving Thermal Management of Batteries with COMSOL Multiphysics®

Webinar

May 09

Demokratisierung der Multiphysik-Simulation

Webinar

May 08

COMSOL® 中的 CFD 仿真

Webinar

May 08

Comment utiliser le solveur temporel de COMSOL Multiphysics®

Webinar

Apr 24

将随频率变化的数据融入 COMSOL® 时域声学仿真

Webinar

Apr 24

Modéliser les Batteries avec COMSOL Multiphysics®

Webinar

Apr 17

COMSOL® 中的电池仿真

Webinar

Apr 17

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Apr 15

Optimization in RF and Wave Optics

Webinar

Apr 09

Wave & Ray Optics Modeling with COMSOL®

Webinar

Apr 09

Modellare le scariche elettriche

Webinar

Apr 09

Meshing Your Models in COMSOL Multiphysics®

Webinar

Apr 08

Multiphysics Simulation in Semiconductor Packaging

Webinar

Apr 03

使用 COMSOL® 模拟生物传感器和检测设备

Webinar

Mar 27

Acoustics in Electronics Webinar Series, Part 1: Loudspeakers

Webinar

Mar 25

Esperienze di simulazione nell'additive manufacturing: dal design al processo

Webinar

Mar 20

Simulating Electrical Power Systems for the Grid

Webinar

Mar 20

Comment Utiliser Efficacement les Études Stationnaires de COMSOL Multiphysics®

Webinar

Mar 20

Modellierung biomedizinischer Geräte mit COMSOL Multiphysics®

Webinar

Mar 20

Multiphysics Modeling of Electronic Components

Webinar

Mar 20

使用 COMSOL® 模拟电声器件

Webinar

Mar 20

Improving Thermal Management of Batteries with COMSOL Multiphysics®

Webinar

Mar 18

Modéliser les Composants Électroniques avec COMSOL Multiphysics®

Webinar

Mar 13

Modeling Chemical Reactions and Reacting Flows Using COMSOL Multiphysics®

Webinar

Mar 06

使用 COMSOL® 进行锂离子电池模型的参数估计

Webinar

Mar 06

Integrating Frequency-Dependent Data into Time-Domain Acoustics Analysis

Webinar

Feb 27

使用 COMSOL® 模拟放电现象

Webinar

Feb 27

Entwicklung von Leistungselektronik und Kabelsystemen

Webinar

Feb 25

使用 COMSOL® 模拟雷达和天线

Webinar

Feb 20

使用模型管理器进行仿真数据管理

Webinar

Feb 13

LiveLink™ for MATLAB® 和 LiveLink™ for Simulink® 功能简介

Webinar

Jan 09

COMSOL® 中的低频电磁场仿真

Webinar

Jan 03

使用 COMSOL Multiphysics® 优化设计

Webinar

Dec 26

COMSOL® 中的结构力学仿真

Webinar

Dec 19

COMSOL® 中的传热仿真

Webinar

Dec 12

COMSOL® 中的多相流仿真

Webinar

Dec 05

COMSOL Multiphysics® 6.3 版本功能简介

Webinar

Nov 28

COMSOL® 中的转子动力学和多体动力学仿真

Webinar

Nov 21

COMSOL® 求解器介绍及设置方法

Webinar

Nov 14

使用 COMSOL Multiphysics® 模拟声学超材料

Webinar

Nov 07

多物理场仿真结果的处理与可视化

Webinar

Oct 24

COMSOL® 中的等离子体仿真

Webinar

Oct 17

COMSOL® 网格划分功能介绍

Webinar

Oct 10

电力变压器的多物理场仿真

Webinar

Sep 19

使用 COMSOL Multiphysics® 仿真高性能电机

Webinar

Sep 12

不确定性量化在多物理场仿真中的应用

Webinar

Sep 05

超声波及其应用的多物理场仿真

Webinar

Aug 29

使用 COMSOL Multiphysics® 模拟光电半导体

Webinar

Aug 15

COMSOL® 多物理场仿真加速数字岩心技术发展

Webinar

Aug 08

使用代理模型开发高效的 COMSOL® 仿真 App

Webinar

Aug 01

COMSOL® 多物理场仿真在地热能开发中的应用

Webinar

Jul 25

COMSOL® 仿真 App 开发、部署和应用

Webinar

Jul 18

COMSOL® 中的光学仿真

Webinar

Jul 11

非线性结构材料参数估计

Webinar

Jul 04

基于 COMSOL® 构建电力设备的数字孪生

Webinar

Jun 27

COMSOL® 室内声学仿真

Webinar

Jun 20

COMSOL Multiphysics® 在半导体制造中的应用

Webinar

Jun 13

COMSOL Multiphysics® 在绿氢技术中的应用

Webinar

Jun 06

使用 COMSOL Multiphysics® 模拟放电现象

Webinar

May 28

使用 COMSOL® 模拟 SAW/BAW 器件

Webinar

May 16

COMSOL® 中的换热器仿真

Webinar

May 09

COMSOL Multiphysics® 中的流固耦合仿真

Webinar

Apr 18

多尺度电磁波仿真

Webinar

Apr 11

COMSOL® 微执行器和微型电机仿真

Webinar

Apr 02

COMSOL® 中的湍流仿真

Webinar

Mar 26

COMSOL® 仿真在电力电子技术中的应用

Webinar

Mar 14

COMSOL® 中的流体动压轴承仿真

Webinar

Mar 12

使用 COMSOL Multiphysics® 模拟 EMI/EMC 现象

Webinar

Mar 07

COMSOL® 中的热辐射仿真

Webinar

Mar 05

使用 COMSOL Multiphysics® 模拟 MEMS 加速度计和陀螺仪

Webinar

Feb 29

Showing 6 of 180 events

Showing 180 of 180 events

Trainings by Certified Consultants

- Product Information

- Products

- Specification Chart

- License Options

- System Requirements

- Release History

- Support and Services

- Support Center

- My Support Cases

- Knowledge Base

- Partners and Consultants

- Documentation

- Product Download

- Company

- About

- Careers

- Press

- Contact Us

- |

- Privacy Policy

- |

- Trademarks

- |

- Cookie Settings

- © 2026 by COMSOL. All rights reserved