See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

A model for material damping is presented in terms of internal friction and in terms of a variation of stiffness. In the latter case the idea is that the stiffness increases if elastic energy is stored and decreases if elastic energy is released. In case of a single mass spring system ... Read More

Micro impact extrusion is investigated at Chemnitz University of Technology as a potential procedure for large area machining of micro cavities within the scope of the SFB/Transregio 39 PT-PIESA of the German Research Foundation. Applying impact extrusion micro forming is done by ... Read More

The increasing demand for improved metallurgical products strongly motivates the optimization of manufacturing processes and design of γ-TiAl products. Among the large variety of available forming processes, cold closed-die forging is particularly suitable for producing net shape ... Read More

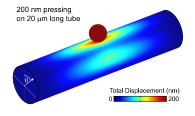

Strain induced by local deformation of a flexible micrometer-sized semiconductor tube is quantified by modeling a ball pressing on the tube wall. By changing the pressing condition, we are able to change the strain state of the tube wall incorporating self-assembled quantum dots (QDs) in ... Read More

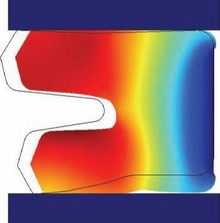

This paper presents a hybrid finite element – finite volume algorithm for solving multi-scale fluid-structure interaction during transient operation of a hydraulic rod seal. The elasto-hydrodynamic model consists of several micro-scale and macro-scale analyses types, all incorporated in ... Read More

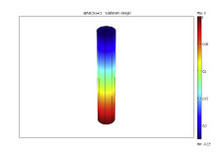

The residual stresses developed in a stiffened panel manufactured using Electron Beam Freeform Fabrication (EBF3) process were studied. EBF3 process is a layer additive process that can be used to build near-net shaped parts directly using computer controlled techniques, which can be ... Read More

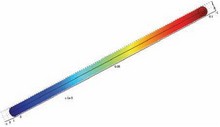

This paper describes the use of structural mechanics capabilities within COMSOL to explore new cooling catheter designs. Cooling catheters may be used to save ischemic tissue resulting from strokes or heart attacks. Typical guide catheters use metallic braiding to ensure torsional ... Read More

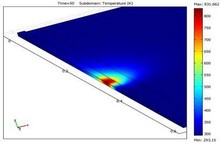

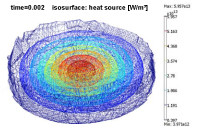

Additive Layer Manufacturing (ALM) methods, like Electron Beam Sintering (EBS), constitute an interesting process concerning the production of small series and customized products. However, transient effects occur during processing due to the different physical principles of an electron ... Read More

The Cosserat models fall into the group of the extended continuum media. They are capable of treating the size effects (characteristic length) in a natural manner using six material moduli for the isotropic elastic cases instead of two (and) for the classical continuum mechanics. This ... Read More

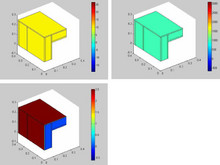

An attempt was made, as described in this paper, to assign material properties like shear strength and modulus of elasticity randomly. In this way, the behaviour of a masonry wall with a prefabricated concrete lintel was experimentally tested and simulated using COMSOL. The paper ... Read More