According to a study done by Brunel University in the United Kingdom, the food sector is among the top five energy-consuming industries. The transportation of food, including keeping it refrigerated, is one of the larger contributing factors to this energy-consumption and subsequent greenhouse gas emissions.

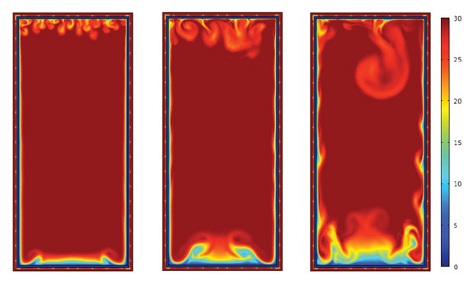

The natural convection and temperature distribution during cooling.

Sunwell Technologies work with a technology that combats this. They manufacture machines that produce and re-charge a refrigeration fluid known as Variable-State Ice or Deepchill™. This is an environmentally-friendly fluid that can be incorporated into refrigerators (known as thermo batteries) in trucks and the like that keep food and similar items chilled. When the truck has reached its destination, the Deepchill fluid is re-charged using off-peak power. This is far more effective and environmentally-friendly than directly using diesel motors on these trucks to keep the produce chilled.

It is quite difficult to use experiments and prototypes to optimize thermo batteries, particularly as they can be big, and they vary in size and operating parameters from truck to truck. Sunwell turned to modeling to help them understand the process and collaborated with the University of Massachusetts, Dartmouth to do this.

The Computational Multiphase Flows Group performed the simulations on a cluster consisting of 72 nodes, each with two Intel Xeon (quad-core) processors. They were able to model the non-isothermal flow and heat transfer of the ice slurry, and allowed Sunwell investigate specific design criteria. Read more on page 40 in COMSOL News.

Comments (0)