COMSOL Events Calendar

Modeling Workflow

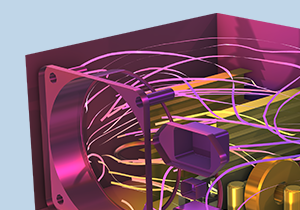

Electromagnetics

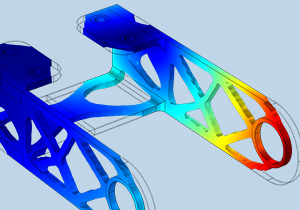

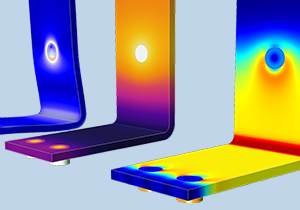

Structural & Acoustics

Fluid & Heat

Chemical

Interfacing

General

Show as:

Time zone:

My Time (EDT)

Host Time

08:00 AM - 08:00 PM

Showing events starting between: 8 a.m. – 8 p.m.

Search

Upcoming Events

Loading Events

Apr 30–May 2

| 11:00 a.m. EDT

Electrochemistry & Electrodeposition Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

May 2

| 10:00 a.m. BST

The Thermal Parameterisation and Modelling of Lithium-ion Batteries

IMechE

Webinar

Online

May 2

| 11:00 a.m. EDT

COMSOL Multiphysics Seminar - Together with CMC Microsystems

COMSOL

Seminar

Online

May 7

| 8:00 a.m. CEST

Equation-Based Modeling with COMSOL®

COMSOL

Webinar

Online

May 7

| 11:30 a.m. EDT

The Basics of COMSOL Multiphysics® in 18 Minutes

COMSOL

Webinar

Online

May 9

| 2:00 p.m. EDT

Simulating Plasmonics and Metamaterials Using COMSOL Multiphysics®

SPIE

Webinar

Online

May 14–17

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

May 14

| 11:30 a.m. EDT

Introducción a COMSOL Multiphysics® en 18 Minutos

COMSOL

Webinar

Online

May 16

| 8:30 a.m. CEST

Modellare e gestire geometrie complesse

COMSOL

Webinar

Online

May 16

| 11:00 a.m. EDT

COMSOL Day: MEMS

COMSOL

COMSOL Day

Online

May 21

| 8:00 a.m. CEST

The Basics of COMSOL® in 18 Minutes

COMSOL

Webinar

Online

May 21

| 8:30 a.m. CEST

Digital twin e modelli surrogati: un passo verso il futuro

COMSOL

Webinar

Online

May 21

| 2:00 p.m. EDT

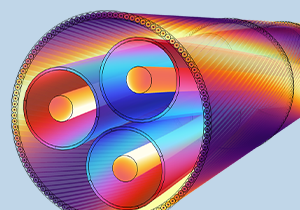

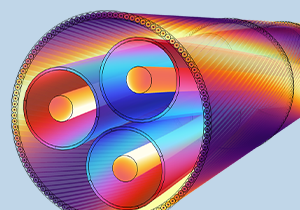

Modeling Cable Design & Power Electronics

IEEE Spectrum

Webinar

Online

Jun 4

| 8:00 a.m. CEST

CFD Modeling with COMSOL® in 18 Minutes

COMSOL

Webinar

Online

Jun 4–7

| 11:00 a.m. EDT

Wave & Ray Optics Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Jun 6

| 2:00 p.m. EDT

Modeling MEMS Accelerometers Using COMSOL Multiphysics®

Machine & Electronic Design

Webinar

Online

Jun 18

| 8:00 a.m. CEST

Modeling Cables with COMSOL® in 18 Minutes

COMSOL

Webinar

Online

Jun 18–21

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Jul 9–12

| 11:00 a.m. EDT

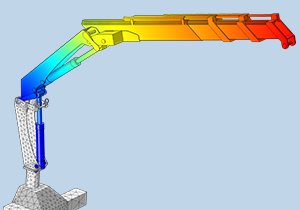

Structural Mechanics Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Jul 23–26

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Aug 6–9

| 11:00 a.m. EDT

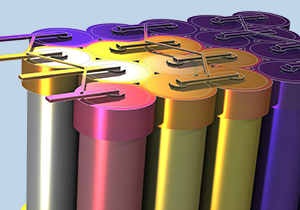

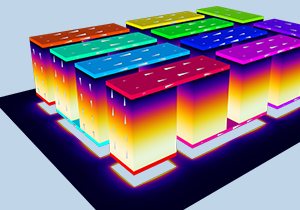

Battery Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Aug 27–30

| 11:00 a.m. EDT

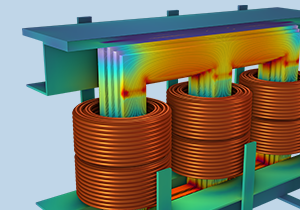

AC/DC Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Sep 5–6

| 9:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Burlington

Sep 24–27

| 11:00 a.m. EDT

Introduction to COMSOL Multiphysics®

COMSOL

Training Course

Online

Oct 2–4

| 8:00 a.m. EDT

COMSOL Conference 2024 Boston

COMSOL

Conference

Burlington

Oct 8–11

| 11:00 a.m. EDT

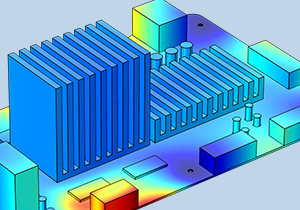

Heat Transfer Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Oct 15–18

| 11:00 a.m. EDT

RF Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Oct 29–Nov 1

| 11:00 a.m. EDT

Acoustics Modeling in COMSOL Multiphysics®

COMSOL

Training Course

Online

Showing 8 of 28 events

Showing 28 of 28 events

| Date | Time | Title | Type | Host | Discipline |

|---|---|---|---|---|---|

| Apr 30–May 2 | 11:00 a.m. |

Electrochemistry & Electrodeposition Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| May 2 | 10:00 a.m. |

The Thermal Parameterisation and Modelling of Lithium-ion Batteries |

Webinar | IMechE - Online |

|

| May 2 | 11:00 a.m. |

COMSOL Multiphysics Seminar - Together with CMC Microsystems |

Special Event | COMSOL-Online |

|

| May 7 | 8:00 a.m. |

Equation-Based Modeling with COMSOL® |

Webinar | COMSOL-Online |

|

| May 7 | 11:30 a.m. |

The Basics of COMSOL Multiphysics® in 18 Minutes |

Webinar | COMSOL-Online |

|

| May 9 | 2:00 p.m. |

Simulating Plasmonics and Metamaterials Using COMSOL Multiphysics® |

Webinar | SPIE - Online |

|

| May 14–17 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| May 14 | 11:30 a.m. |

Introducción a COMSOL Multiphysics® en 18 Minutos |

Webinar | COMSOL-Online |

|

| May 16 | 8:30 a.m. |

Modellare e gestire geometrie complesse |

Webinar | COMSOL-Online |

|

| May 16 | 11:00 a.m. |

COMSOL Day: MEMS |

COMSOL Day | COMSOL-Online |

|

| May 21 | 8:00 a.m. |

The Basics of COMSOL® in 18 Minutes |

Webinar | COMSOL-Online |

|

| May 21 | 8:30 a.m. |

Digital twin e modelli surrogati: un passo verso il futuro |

Webinar | COMSOL-Online |

|

| May 21 | 2:00 p.m. |

Modeling Cable Design & Power Electronics |

Webinar | IEEE Spectrum - Online |

|

| Jun 4 | 8:00 a.m. |

CFD Modeling with COMSOL® in 18 Minutes |

Webinar | COMSOL-Online |

|

| Jun 4–7 | 11:00 a.m. |

Wave & Ray Optics Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Jun 6 | 2:00 p.m. |

Modeling MEMS Accelerometers Using COMSOL Multiphysics® |

Webinar | Machine & Electronic Design - Online |

|

| Jun 18 | 8:00 a.m. |

Modeling Cables with COMSOL® in 18 Minutes |

Webinar | COMSOL-Online |

|

| Jun 18–21 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Jul 9–12 | 11:00 a.m. |

Structural Mechanics Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Jul 23–26 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Aug 6–9 | 11:00 a.m. |

Battery Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Aug 27–30 | 11:00 a.m. |

AC/DC Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Sep 5–6 | 9:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Burlington |

|

| Sep 24–27 | 11:00 a.m. |

Introduction to COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Oct 2–4 | 8:00 a.m. |

COMSOL Conference 2024 Boston |

Special Event | COMSOL-Burlington |

|

| Oct 8–11 | 11:00 a.m. |

Heat Transfer Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Oct 15–18 | 11:00 a.m. |

RF Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

| Oct 29–Nov 1 | 11:00 a.m. |

Acoustics Modeling in COMSOL Multiphysics® |

Training Course | COMSOL-Online |

|

Trainings by Certified Consultants

On-Demand Webinars

COMSOL Multiphysics® 波動光学及び光線光学モジュールのご紹介

Special Event

Apr 26

Comment construire efficacement sa géométrie avec le module Design

Webinar

Apr 25

COMSOL Multiphysics® 在生物传感器中的仿真应用

Webinar

Apr 25

Designing a Novel Multimodal Piezoelectric Energy Harvester Using COMSOL Multiphysics®

Webinar

Apr 25

Electromagnetic Heating Simulation – Emerging Medical Applications

Webinar

Apr 24

Modeling Antennas and Wireless Charging for Electronic Devices with COMSOL Multiphysics®

Webinar

Apr 24

Modeling Room Acoustics with COMSOL Multiphysics®

Webinar

Apr 18

COMSOL Multiphysics® 中的流固耦合仿真

Webinar

Apr 18

Additive manufacturing e simulazione: la chiave per l'innovazione

Webinar

Apr 17

Modéliser la Corrosion et les Systèmes de Protection contre la Corrosion avec COMSOL Multiphysics®

Webinar

Apr 16

STOP Analysis with COMSOL Multiphysics®

Webinar

Apr 11

多尺度电磁波仿真

Webinar

Apr 11

COMSOL® 微执行器和微型电机仿真

Webinar

Apr 02

Modeling and Simulation of Power Electronics

Webinar

Mar 28

Advancing Future Energy Storage and Conversion Technologies with Simulation

Webinar

Mar 28

COMSOL® 中的湍流仿真

Webinar

Mar 26

Modeling Optical Nanostructures with COMSOL Multiphysics®

Webinar

Mar 21

Progettare motori elettrici più efficienti con la simulazione

Webinar

Mar 21

Comment construire un Maillage personnalisé dans COMSOL Multiphysics®

Webinar

Mar 21

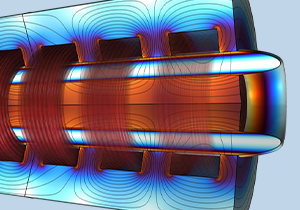

Designing RF Launchers for Nuclear Applications using COMSOL Multiphysics®

Webinar

Mar 20

Modeling Corrosion using COMSOL Multiphysics®

Webinar

Mar 15

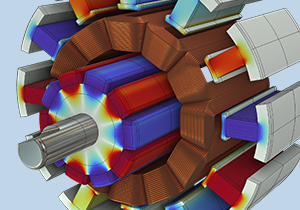

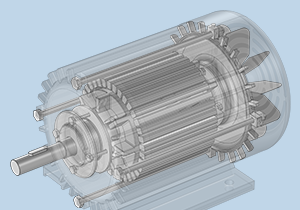

Multiphysics Modeling of Electrical Motors

Webinar

Mar 14

Améliorer la Gestion Thermique des Batteries avec COMSOL Multiphysics®

Webinar

Mar 14

COMSOL® 仿真在电力电子技术中的应用

Webinar

Mar 14

Modeling Optics and Photonics in COMSOL®

Webinar

Mar 13

COMSOL® 中的流体动压轴承仿真

Webinar

Mar 12

使用 COMSOL Multiphysics® 模拟 EMI/EMC 现象

Webinar

Mar 07

COMSOL® 中的热辐射仿真

Webinar

Mar 05

Training Surrogate Models to Build Faster Simulation Apps

Webinar

Feb 29

使用 COMSOL Multiphysics® 模拟 MEMS 加速度计和陀螺仪

Webinar

Feb 29

Microfluidics Modeling in COMSOL Multiphysics®

Webinar

Feb 22

Simulare le tecnologie dell'idrogeno: dagli elettrolizzatori alle fuel cell

Webinar

Feb 20

Comment configurer le Solveur Temporel de COMSOL Multiphysics®

Webinar

Feb 20

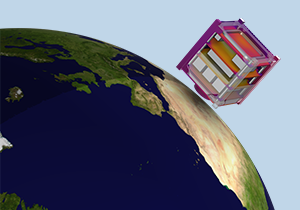

Analyzing Spacecraft Thermal Performance with COMSOL®

Webinar

Feb 15

Modéliser les Dispositifs Médicaux avec COMSOL Multiphysics®

Webinar

Feb 15

Introducción a COMSOL Multiphysics® en 18 Minutos

Webinar

Feb 13

Parameter Estimation for Nonlinear Materials

Webinar

Feb 08

Modeling Electroacoustic Transducers

Webinar

Feb 07

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Feb 06

Simulare fenomeni di convezione

Webinar

Jan 30

Modeling Eddy Current Inductive Sensors in COMSOL®

Webinar

Jan 25

在 COMSOL Multiphysics® 中模拟腐蚀及防护系统

Webinar

Jan 25

Comment configurer le Solveur Stationnaire de COMSOL Multiphysics®

Webinar

Jan 23

Améliorer les Performances des Piles à Combustible et des Electrolyseurs avec COMSOL Multiphysics®

Webinar

Jan 18

Multiphysics Simulation for Solar Energy Applications

Webinar

Jan 18

使用 COMSOL® 模拟等离激元效应和超材料

Webinar

Jan 18

Cosa c'è di nuovo in COMSOL Multiphysics® 6.2

Webinar

Jan 16

半导体封装和测试中的多物理场仿真

Webinar

Jan 11

COMSOL® 中的扬声器和麦克风仿真

Webinar

Jan 04

使用 COMSOL Multiphysics® 进行结构-热-光学耦合分析

Webinar

Dec 21

Modeling Magnetic Cores in Transformers and Electric Machines using COMSOL Multiphysics®

Webinar

Dec 20

Improving Electric Drivetrain Efficiency with Multiphysics Simulation

Webinar

Dec 15

Battery Modeling with COMSOL Multiphysics®

Webinar

Dec 14

Comment faire de l’Estimation de Paramètres avec COMSOL Multiphysics®

Webinar

Dec 14

Multiphysics Modeling of Electronic Components

Webinar

Dec 07

Modélisation Multiphysique des Procédés de Soudage, de Fabrication Additive et de Découpe Laser

Webinar

Dec 07

Modellare gli accoppiamenti multifisici nelle analisi strutturali

Webinar

Dec 05

COMSOL® 多物理场仿真在电气绝缘中的应用

Webinar

Dec 05

Lightning Strikes: Insights and Solutions Using Multiphysics Modeling

Webinar

Dec 01

Design and Optimization of Optical Waveguides

Webinar

Nov 30

How to Interface COMSOL Multiphysics® with MATLAB®

Webinar

Nov 30

微流体器件的多物理场仿真

Webinar

Nov 30

半导体制造中的晶体生长仿真

Webinar

Nov 28

Progettare sistemi elettrici ed elettronici per l'automotive

Webinar

Nov 23

Modéliser les Procédés Pharmaceutiques avec COMSOL Multiphysics®

Webinar

Nov 23

Advancing Rail Technology Innovation with COMSOL Multiphysics®

Webinar

Nov 22

COMSOL® 多物理场仿真在医疗设备研发中的应用

Webinar

Nov 21

Unlocking the Future: How Digital Twins Are Revolutionizing Our World

Webinar

Nov 16

COMSOL® 中的网格划分

Webinar

Nov 16

Unire mondo reale e virtuale con i digital twin

Webinar

Nov 15

锂离子电池热失控仿真

Webinar

Nov 14

COMSOL® 中的磁流体仿真

Webinar

Nov 09

Modeling Optical Nanostructures with COMSOL Multiphysics®

Webinar

Nov 08

Multiphysics Simulation for Enhanced Electric Drivetrain Efficiency

Webinar

Nov 07

Adapting the Electrical Grid for Green Energy

Webinar

Nov 02

COMSOL® 地下水流及多孔介质流仿真

Webinar

Nov 02

Simulating Light-Tissue Interaction using COMSOL Multiphysics®

Webinar

Oct 31

电磁噪声的仿真分析

Webinar

Oct 31

使用 COMSOL Multiphysics® 仿真 PVD/CVD 薄膜沉积工艺

Webinar

Oct 27

Dal flusso laminare al turbolento: tecniche di simulazione per la CFD

Webinar

Oct 25

Learn About Simulating Plasmonics and Metamaterials

Webinar

Oct 24

COMSOL® 多物理场仿真优化电缆设计

Webinar

Oct 20

Modeling Cables with COMSOL® in 18 Minutes

Webinar

Oct 19

Modéliser le Rayonnement Thermique

Webinar

Oct 19

COMSOL® 的求解器简介

Webinar

Oct 13

Comment transformer vos modèles en applications de simulation

Webinar

Oct 12

Trasporto e termodinamica nelle simulazioni chimiche

Webinar

Oct 11

Modeling and Simulation of Power Electronics

Webinar

Oct 05

Battery Modeling with COMSOL Multiphysics®

Webinar

Oct 03

Comment Exploiter efficacement vos Résultats de Simulation

Webinar

Sep 28

Simulating Band Gaps and Scattering in Phononic Crystals with COMSOL Multiphysics®

Webinar

Sep 28

Design Optimization for Engineering Problems — from Nanophotonics to Civil Infrastructure

Webinar

Sep 27

Machine learning e simulazione: una coppia vincente

Webinar

Sep 27

Improving Electric Drivetrain Efficiency with Multiphysics Simulation

Webinar

Sep 26

COMSOL® 中的感应加热仿真

Webinar

Sep 26

Modeling MEMS Accelerometers Using COMSOL Multiphysics®

Webinar

Sep 21

Modéliser la Corrosion et les Systèmes de Protection contre la Corrosion avec COMSOL Multiphysics®

Webinar

Sep 21

Come scegliere i materiali per la resistenza meccanica

Webinar

Sep 20

COMSOL® 中的岩土力学仿真

Webinar

Sep 19

多物理场仿真在激光加工中的应用

Webinar

Sep 15

计算流体力学(CFD)多物理场仿真

Webinar

Sep 12

使用 COMSOL® 求解大型模型

Webinar

Sep 08

Modeling Reaction Kinetics and Pharmacokinetics with COMSOL®

Webinar

Sep 07

COMSOL® 中的声学超材料仿真

Webinar

Sep 05

使用 COMSOL Multiphysics® 进行设计优化

Webinar

Sep 01

Reducing the Need for Physical Prototyping with Sensor Design

Webinar

Aug 31

Multiphysics Modeling of Manufacturing Processes Using COMSOL®

Webinar

Aug 31

Semplifica la gestione dei modelli con il Model Manager

Webinar

Aug 31

Comment utiliser des fonctionnalités du COMSOL Desktop® pour gagner en efficacité

Webinar

Aug 31

COMSOL® 的压电材料和器件仿真

Webinar

Aug 29

COMSOL® 中的变压器仿真

Webinar

Aug 25

Multiphysics Modeling and Simulation for 5G Devices

Webinar

Aug 24

Lightweighting in EVs with Multiphysics Simulation

Webinar

Aug 23

COMSOL® 中的半导体器件仿真

Webinar

Aug 22

COMSOL® 中的锂电池仿真

Webinar

Aug 18

Multiphysics Software for Optics Simulation

Webinar

Aug 17

Using COMSOL Multiphysics® for Teaching in Academia

Webinar

Aug 16

COMSOL® 的结构力学仿真

Webinar

Aug 15

COMSOL® 中的 LiveLink™ for MATLAB® 和 LiveLink™ for Simulink® 功能简介

Webinar

Aug 11

Optimization of Automotive Components with Multiphysics Simulation

Webinar

Aug 10

电子设备热管理的仿真分析

Webinar

Aug 04

电磁损耗的仿真分析

Webinar

Jul 28

Multiphysics Modeling and Simulation for 5G Devices

Webinar

Jul 27

Fuel Cell Simulation with COMSOL Multiphysics®

Webinar

Jul 26

氢燃料电池与水电解槽的多物理场仿真

Webinar

Jul 25

COMSOL® 中的多相流仿真

Webinar

Jul 21

Modeling and Simulation of Power Electronics

Webinar

Jul 20

Comment Configurer le Solveur Temporel dans COMSOL Multiphysics®

Webinar

Jul 20

Condividi i tuoi modelli con le app di simulazione

Webinar

Jul 18

粒子追踪方法的建模仿真

Webinar

Jul 18

MEMS 器件的多物理场建模和仿真

Webinar

Jul 14

EMF Grenzwerte - Mehr Sicherheit am Arbeitsplatz durch Simulation

Webinar

Jul 12

SAW 和 BAW 滤波器的建模仿真

Webinar

Jul 07

Modeling Turbulent Flow with COMSOL®

Webinar

Jul 06

Il ruolo della simulazione nel futuro del settore aerospaziale

Webinar

Jul 04

COMSOL® 中的电镀仿真

Webinar

Jul 04

COMSOL® 中的射线光学仿真

Webinar

Jun 30

Comment transformer vos modèles en applications de simulation

Webinar

Jun 29

Modéliser l’emballement thermique des batteries avec COMSOL Multiphysics®

Webinar

Jun 22

Improving Battery Safety Design Using Thermal Management Modeling

Webinar

Jun 21

Modeling Thermal Runaway and Abuse in Batteries

Webinar

Jun 21

Warum Batterien modellieren?

Webinar

Jun 20

COMSOL® 中的热应力仿真

Webinar

Jun 16

Modeling Optical Waveguides

Webinar

Jun 15

Thermal Management in Electronic Devices with COMSOL Multiphysics®

Webinar

Jun 15

Come modellare trattamenti termici

Webinar

Jun 14

Introdução ao COMSOL Multiphysics® em 18 minutos

Webinar

Jun 13

COMSOL® 中的高频电磁场仿真

Webinar

Jun 13

COMSOL® 中的流固耦合仿真

Webinar

Jun 09

Progettare tecnologie per eolico e solare

Webinar

Jun 07

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Jun 06

Brennstoffzellen und Elektrolyseure modellieren in 18 Minuten

Webinar

Jun 06

COMSOL® 中的传热仿真

Webinar

Jun 06

COMSOL® 中的腐蚀与防护仿真

Webinar

Jun 02

STOP Analysis with COMSOL Multiphysics®

Webinar

May 31

Fatigue and Durability Analysis of Automotive Components

Webinar

May 31

Introducción a COMSOL Multiphysics® en 18 Minutos

Webinar

May 30

Modeling Periodic Structures in RF and Optics

Webinar

May 30

Introduction to Chemical Reactor Modeling with COMSOL Multiphysics®

Webinar

May 25

Comment configurer le Solveur Stationnaire

Webinar

May 25

COMSOL® 中的低频电磁场仿真

Webinar

May 23

在 COMSOL® 中进行 CAD 导入及几何模型处理

Webinar

May 19

Modeling Electric Motors and Drivetrains

Webinar

May 18

Modeling Magnetohydrodynamic Flow in COMSOL®

Webinar

May 18

Studiare il comportamento reologico dei fluidi

Webinar

May 18

Improving Electric Drivetrain Efficiency with Multiphysics Simulation

Webinar

May 17

COMSOL® 中的复合材料仿真

Webinar

May 16

声学与振动的多物理场仿真

Webinar

May 12

Simulare suono e rumore

Webinar

May 11

Améliorez les Performances de vos Piles à Combustible avec COMSOL Multiphysics®

Webinar

May 11

Modeling Corrosion Processes and CP Systems with COMSOL Multiphysics®

Webinar

May 10

Modellare sistemi ottici in contesti multifisici

Webinar

May 04

Introduction to Uncertainty Quantification in COMSOL Multiphysics®

Webinar

May 03

Comment Améliorer vos Processus de Modélisation grâce au Gestionnaire de Modèles

Webinar

Apr 27

COMSOL® 化学反应工程仿真

Webinar

Apr 18

光学超材料仿真

Webinar

Apr 14

电力设备的多物理场仿真

Webinar

Apr 07

在 COMSOL® 中使用自定义函数建模

Webinar

Mar 31

COMSOL® 6.1 电磁模拟新功能

Webinar

Mar 24

COMSOL® 6.1 电池模块新功能

Webinar

Mar 17

COMSOL® 中的声流仿真

Webinar

Mar 10

COMSOL Multiphysics® 波动光学仿真

Webinar

Mar 07

COMSOL® 6.1 结构力学模块新功能

Webinar

Mar 03

如何使用 COMSOL® 分析航天器热性能

Webinar

Feb 24

COMSOL® 6.1 模型管理器和 App 开发器新功能介绍

Webinar

Feb 17

COMSOL® 6.1 燃料电池和电解槽模块新功能

Webinar

Feb 10

COMSOL® 6.1 声学模块新功能

Webinar

Feb 03

Best Practices for Results and Visualization

Webinar

Jan 18

在 COMSOL® 中基于方程进行建模仿真

Webinar

Jan 13

COMSOL® 6.1 CFD 模块新功能

Webinar

Jan 06

COMSOL LiveLink™ for MATLAB® 功能简介

Webinar

Dec 30

在 COMSOL® 中创建二维几何模型

Webinar

Dec 23

声学超材料的建模和仿真

Webinar

Dec 16

在 COMSOL® 中进行结果后处理与可视化

Webinar

Dec 09

使用 COMSOL® 多物理场仿真优化光学系统设计

Webinar

Nov 25

燃料电池中的多物理场仿真

Webinar

Nov 18

机电效应的多物理场建模和仿真

Webinar

Nov 11

COMSOL® 求解器简介

Webinar

Nov 04

使用 COMSOL® 进行多孔介质流仿真

Webinar

Oct 28

COMSOL Multiphysics® 结构力学仿真

Webinar

Oct 14

Machine learning e simulazione: una coppia vincente

Webinar

Sep 27

COMSOL 中的腐蚀与防护仿真

Webinar

Sep 16

使用 COMSOL 对地质勘探方法进行建模仿真

Webinar

Sep 09

高频电磁场中的多物理场仿真

Webinar

Sep 02

通过 COMSOL 多物理场仿真进行设计优化

Webinar

Aug 26

使用 COMSOL 评估 PCB 与射频器件的电磁性能

Webinar

Aug 19

通过 COMSOL 仿真分析减振降噪

Webinar

Aug 12

COMSOL 中的传热仿真

Webinar

Aug 05

使用 COMSOL 软件优化半导体器件设计

Webinar

Jul 29

电子设备的热管理仿真

Webinar

Jul 26

多物理场仿真在激光加工中的应用

Webinar

Jul 22

在 COMSOL 中求解大型模型

Webinar

Jul 19

计算流体力学(CFD)仿真分析

Webinar

Jul 15

相控阵列天线建模方法

Webinar

Jul 12

在 COMSOL 中构建网格的基本方法

Webinar

Jul 08

使用 COMSOL 进行热应力仿真

Webinar

Jul 01

NVH Analysis for Automotive Applications with Multiphysics Simulation

Webinar

Jun 22

COMSOL 多物理场仿真在地质开采中的应用

Webinar

Jun 17

Improving Battery Performance with Multiphysics Simulation

Webinar

Jun 15

锂电池的多物理场仿真分析

Webinar

Jun 10

COMSOL 等离子体仿真简介

Webinar

May 27

Electromagnetics Applications for Aerospace and Defense

Webinar

May 25

Designing Efficient Electric Motors with Multiphysics Simulation

Webinar

May 18

COMSOL 中几何文件的处理方法简介

Webinar

May 13

Modeling Nondestructive Testing Methods with COMSOL Multiphysics®

Webinar

Apr 27

Showing 6 of 225 events

Showing 225 of 225 events

Trainings by Certified Consultants

- Product Information

- Products

- Specification Chart

- License Options

- System Requirements

- Release History

- Support and Services

- Support Center

- My Support Cases

- Knowledge Base

- Partners and Consultants

- Documentation

- Product Download

- Company

- About

- Careers

- Press

- Contact Us

- |

- Privacy Policy

- |

- Trademarks

- |

- Cookie Settings

- © 2024 by COMSOL. All rights reserved