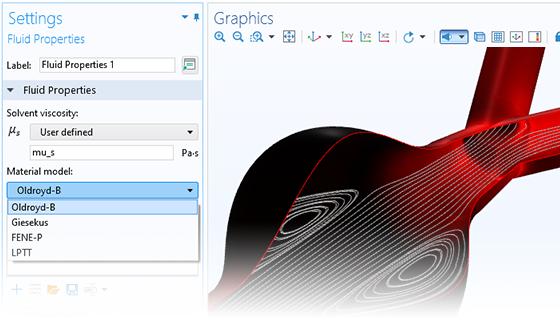

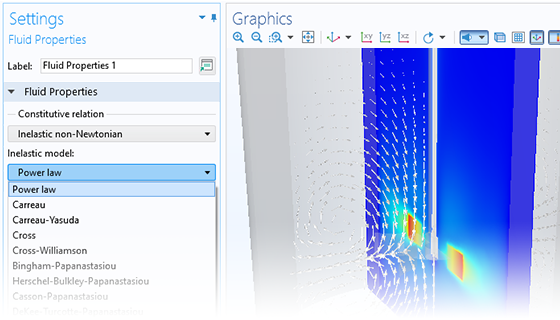

Polymer Melts, Paints, and Protein Suspensions

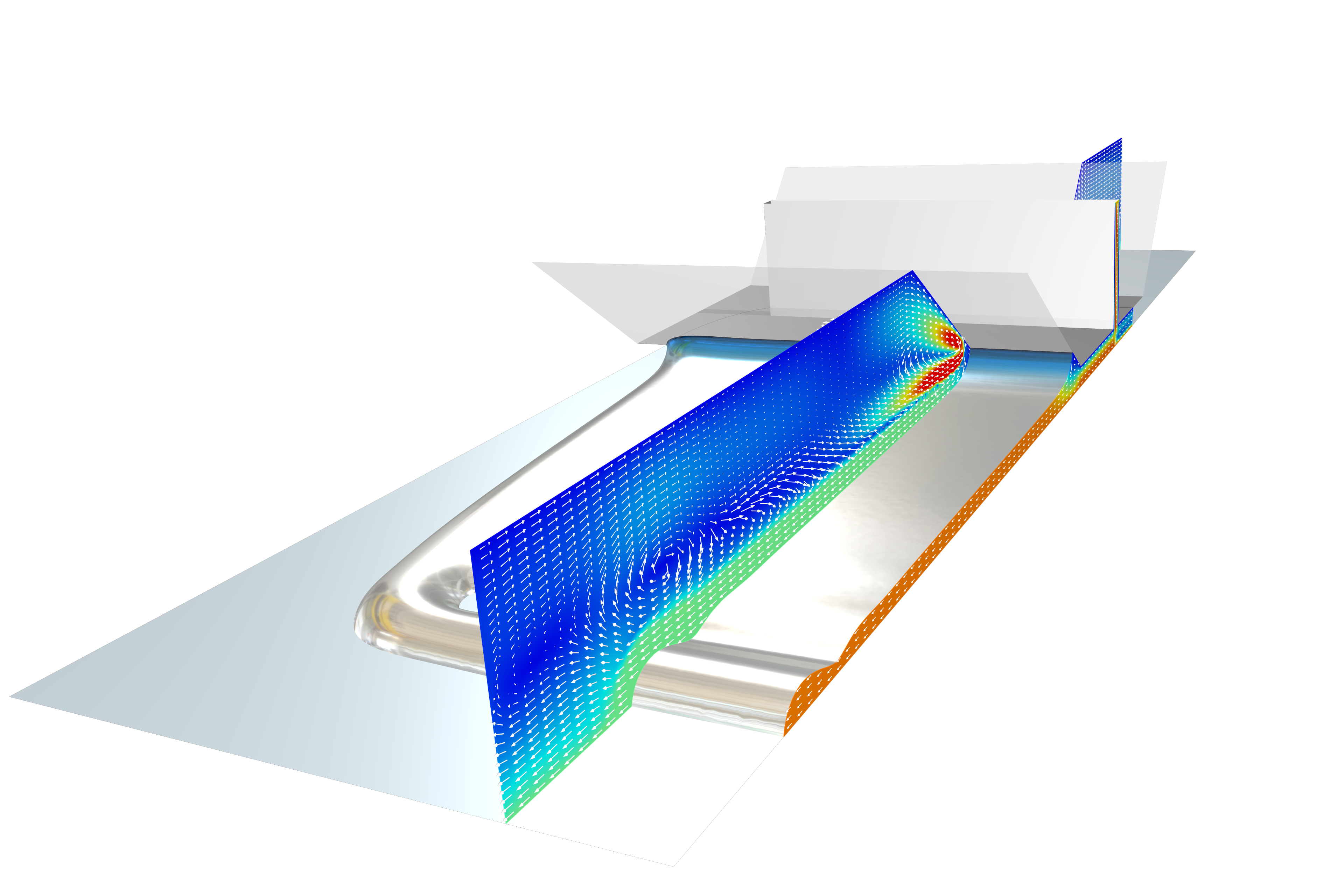

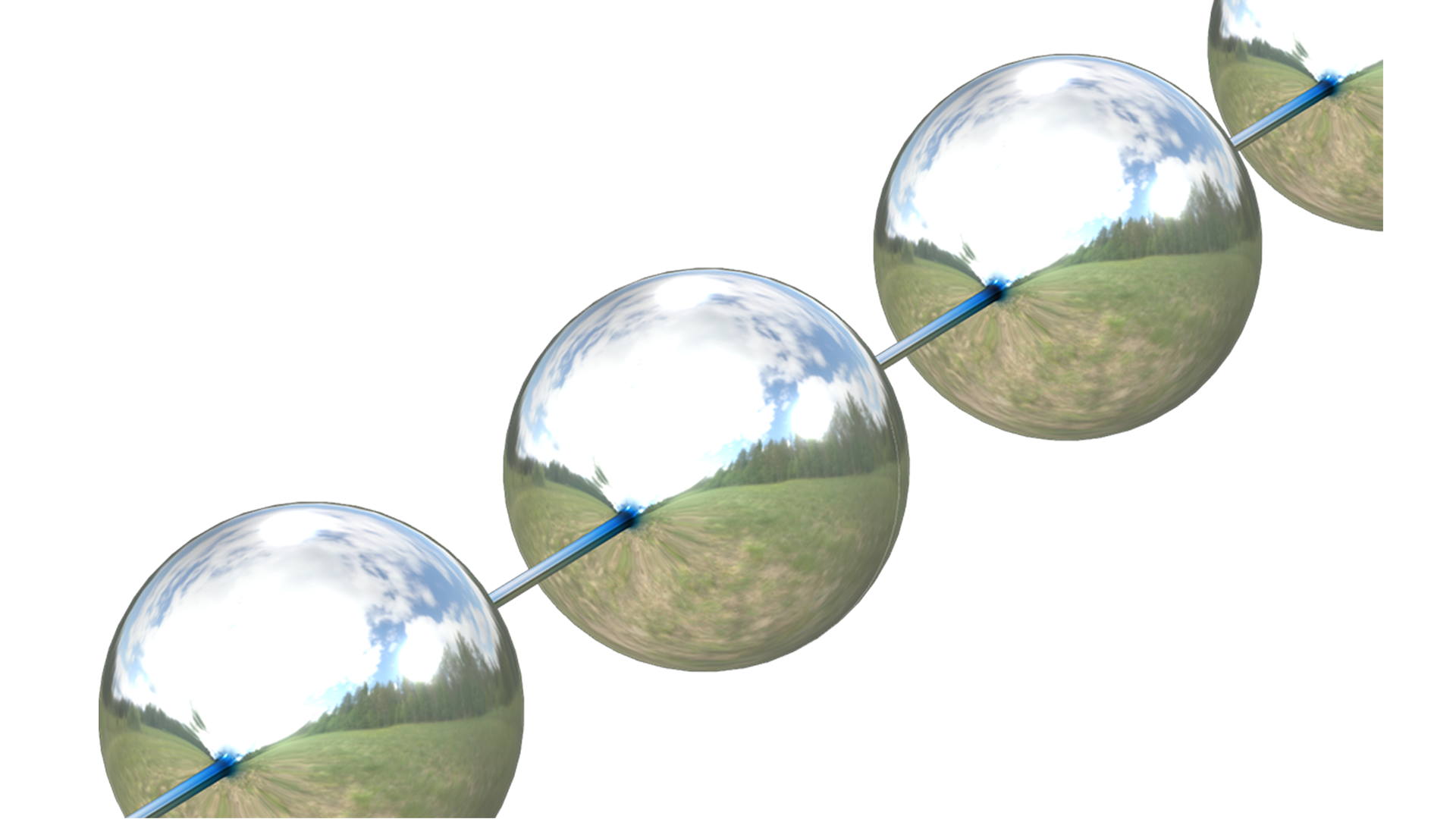

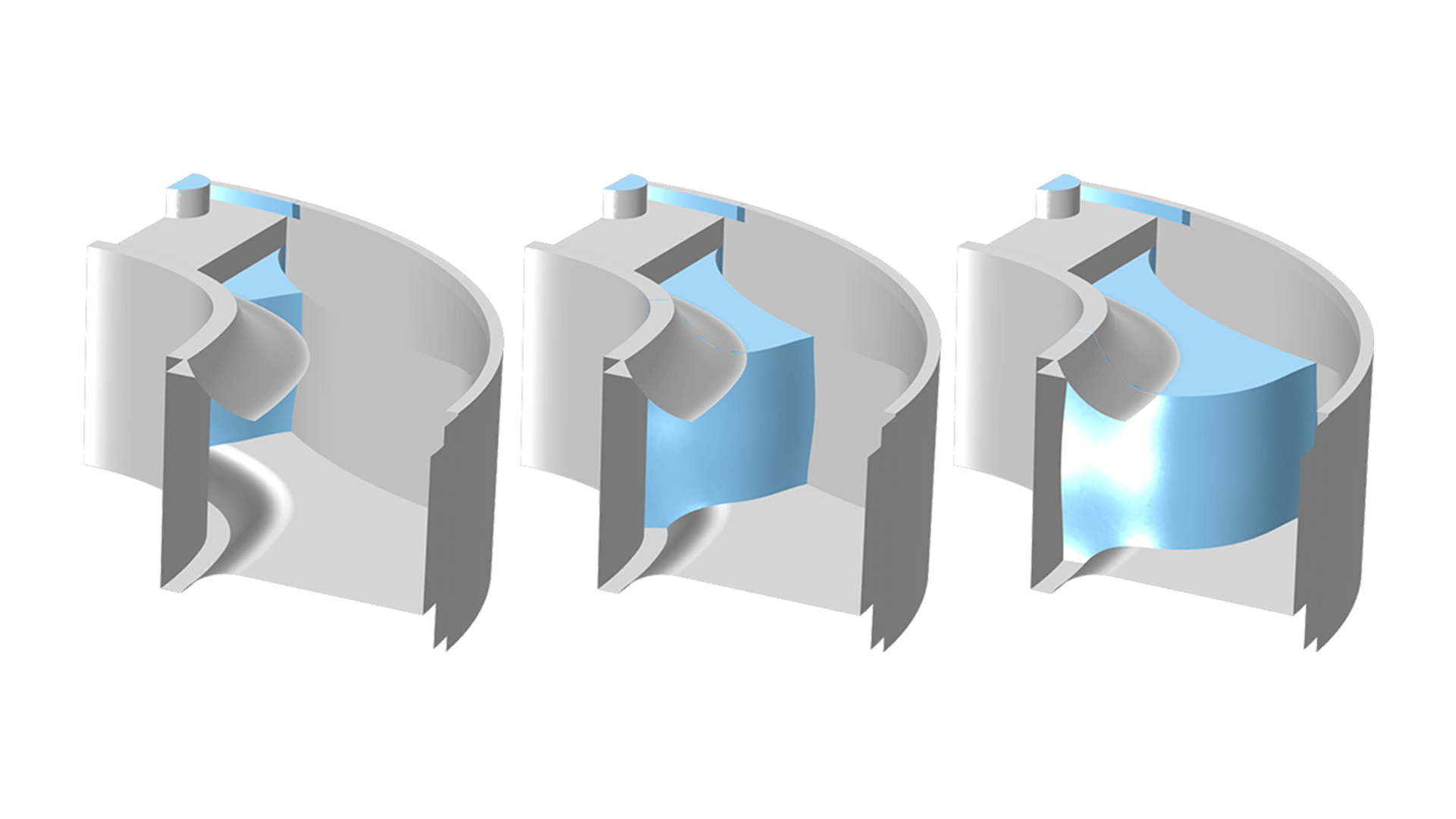

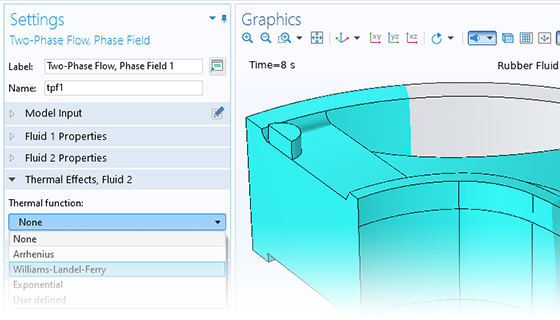

Viscoelastic fluid models account for the elasticity in these types of fluids. As the fluid is deformed, there is a certain amount of force that works toward returning the fluid to its undeformed state. When modeling, it is important to estimate the deformation of the fluid with time (that is, the shape of the air–liquid interface), the local forces on the surfaces that may interact with these fluids, and the pressure losses in a system where the fluid flow occurs. Typical examples of these fluids are polymer melts, paints, and suspensions of proteins.