Importing CAD Files

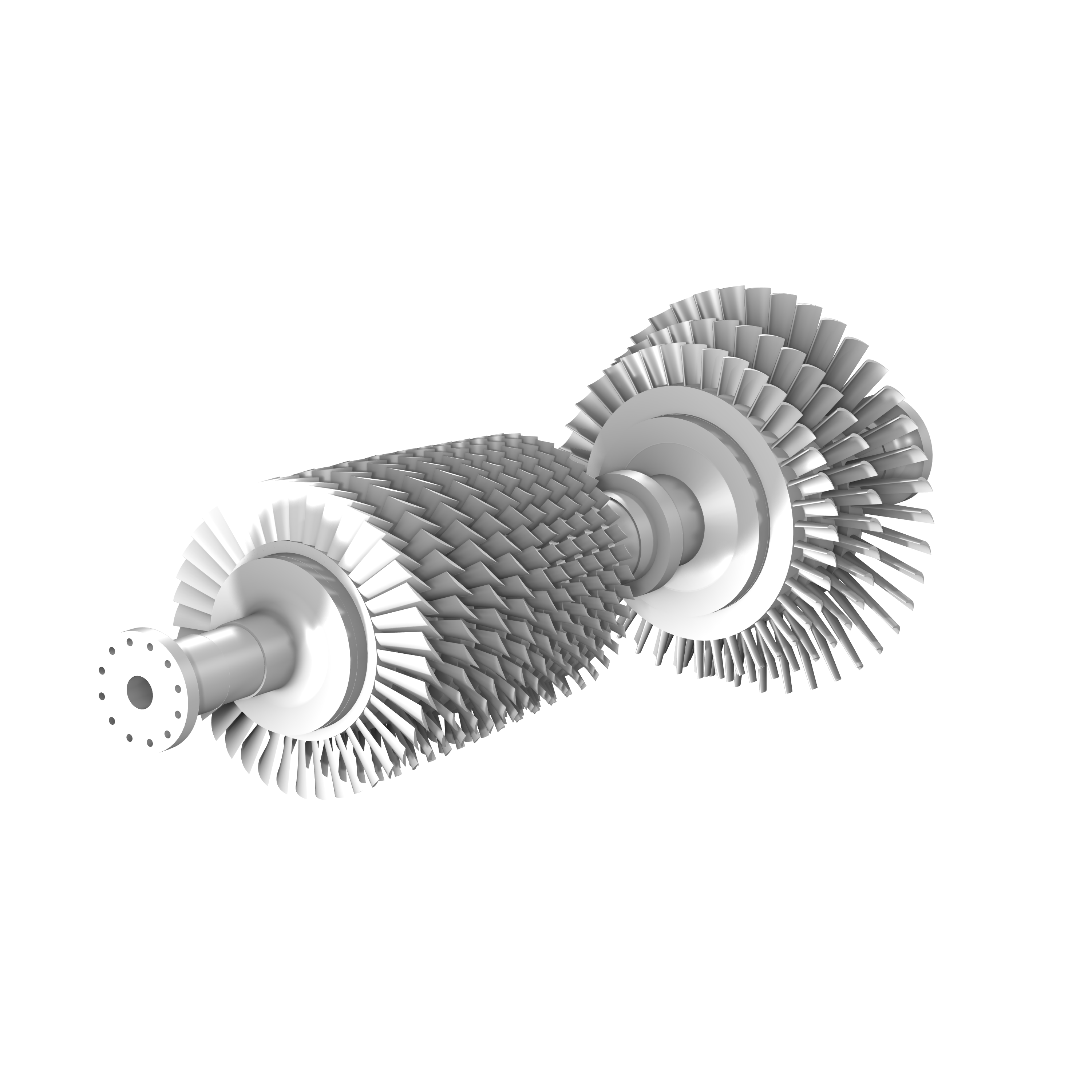

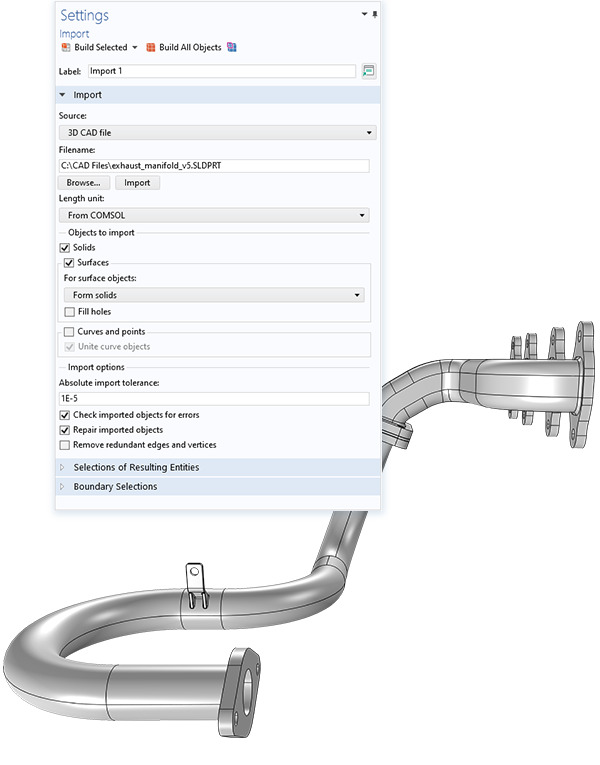

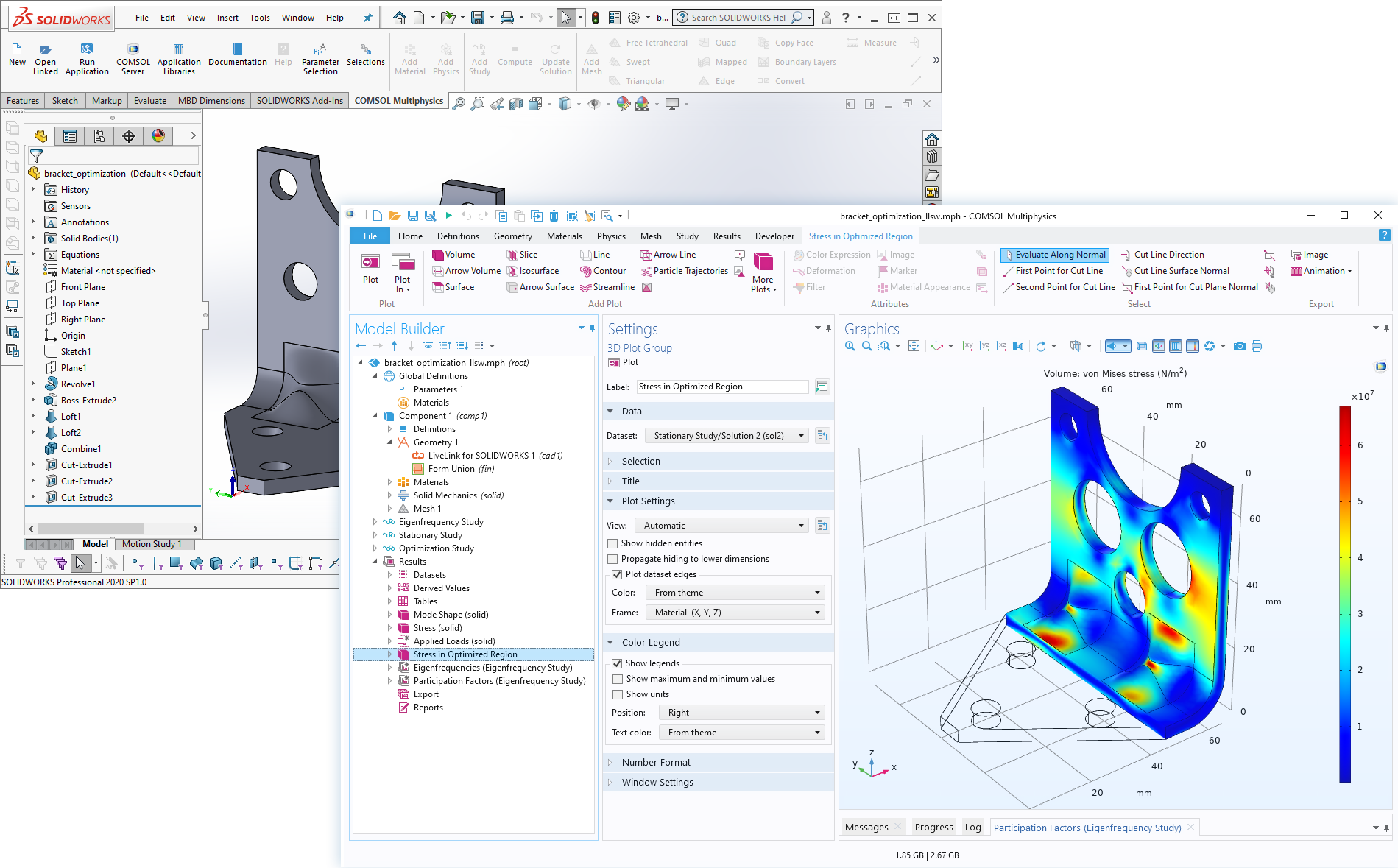

Most CAD software programs support exporting to the Parasolid®, ACIS®, STEP, and IGES file formats, all of which can be readily imported into COMSOL Multiphysics® using the CAD Import Module. In addition, there is support for importing native file formats from several CAD systems, including SOLIDWORKS®, Inventor®, PTC Creo Parametric™, NX™, and AutoCAD®. Support for importing the native file format of CATIA® V5 is provided through the separate File Import for CATIA® V5 add-on. When the CAD Import Module is installed, all imported CAD models are automatically converted into a Parasolid® geometry using the Parasolid® geometry engine included with the module.

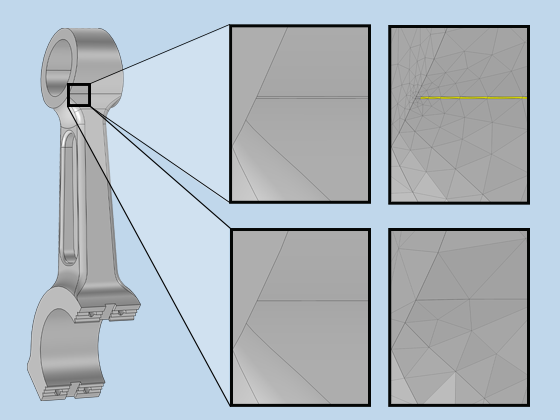

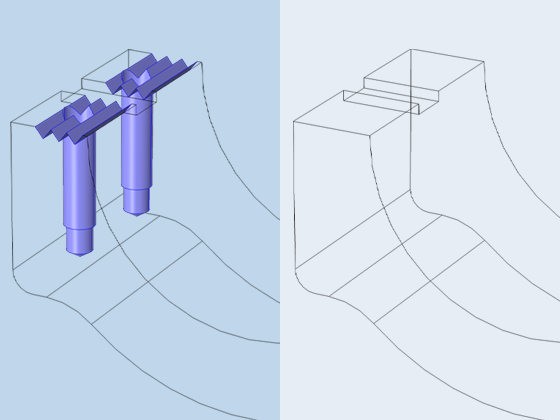

These geometries can subsequently be modified within COMSOL Multiphysics® using the CAD Import Module or the Design Module. In addition to fixing errors, users can make other adjustments, such as creating a surrounding CFD, acoustics, or electromagnetics domain. (Most CAD models represent the object to be manufactured, whereas simulations often focus on the physical phenomena around that object, such as airflow.) Once the modifications are complete, the CAD Import Module can export the updated geometry in IGES, STEP, Parasolid®, or ACIS® formats for use in other tools.

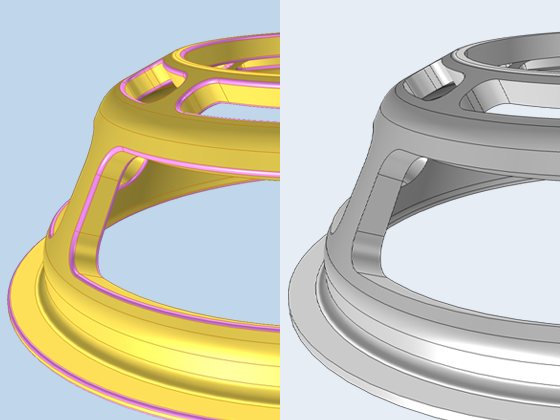

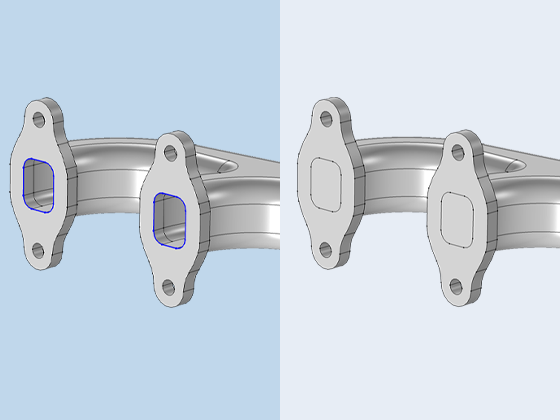

The import functionality supports associative geometry import, allowing physics settings and other selections to be retained on the geometry. When a file is imported, COMSOL Multiphysics® reads the information in the CAD file to identify its geometric entities. If the file is later reimported due to a design change, all selections in COMSOL Multiphysics® are automatically updated and preserved based on associativity rules, reducing the need to repeat setup work. This associative information is typically available when importing CAD files saved in the native format of the software where it was created.